Managing your risk

The benefits of working with Precision Microdrives

- Your trusted motor & mechanism partner.

- Delivering on time and to spec.

- We proactively manage your risk.

Motors and mechanisms are complex components. We manage your exposure to risk from design to mass production.

Our values match yours

As a UK headquartered company we speak your language and respect your values. We can avoid costly miscommunications. We work under confidentiality and protect your intellectual property. We take pride in engineering the best solutions and delivering the best service that we can and strive to offer you even more value on our next project together. In fact, many customers have remarked over the years how we behave and support like a team within their own business.

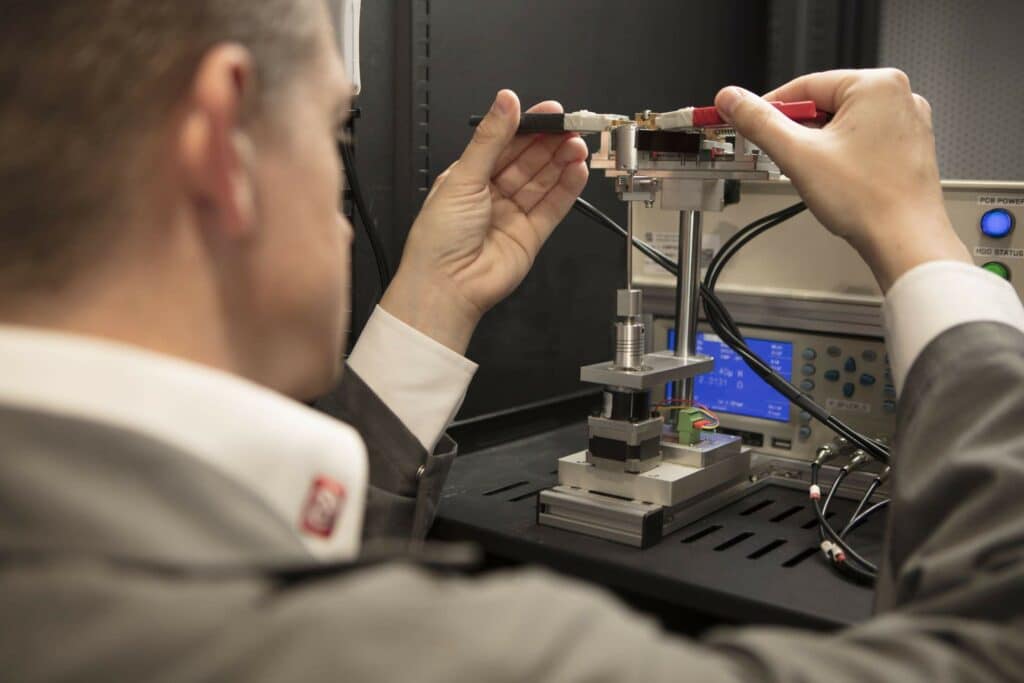

Our expertise can foresee where things could go wrong

It’s our motor engineering expertise and pride in technical diligence that makes Precision Microdrives a design and manufacturing partner you can trust. Since 2004 we’ve witnessed all the ways that motor and mechanism projects can go wrong. We know what you don’t.

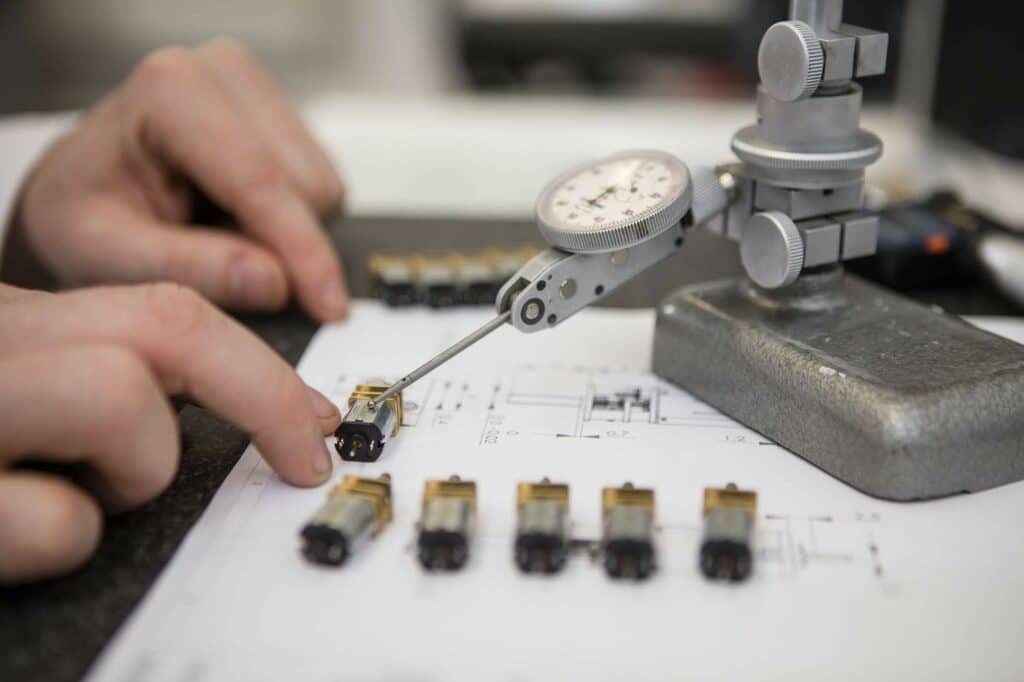

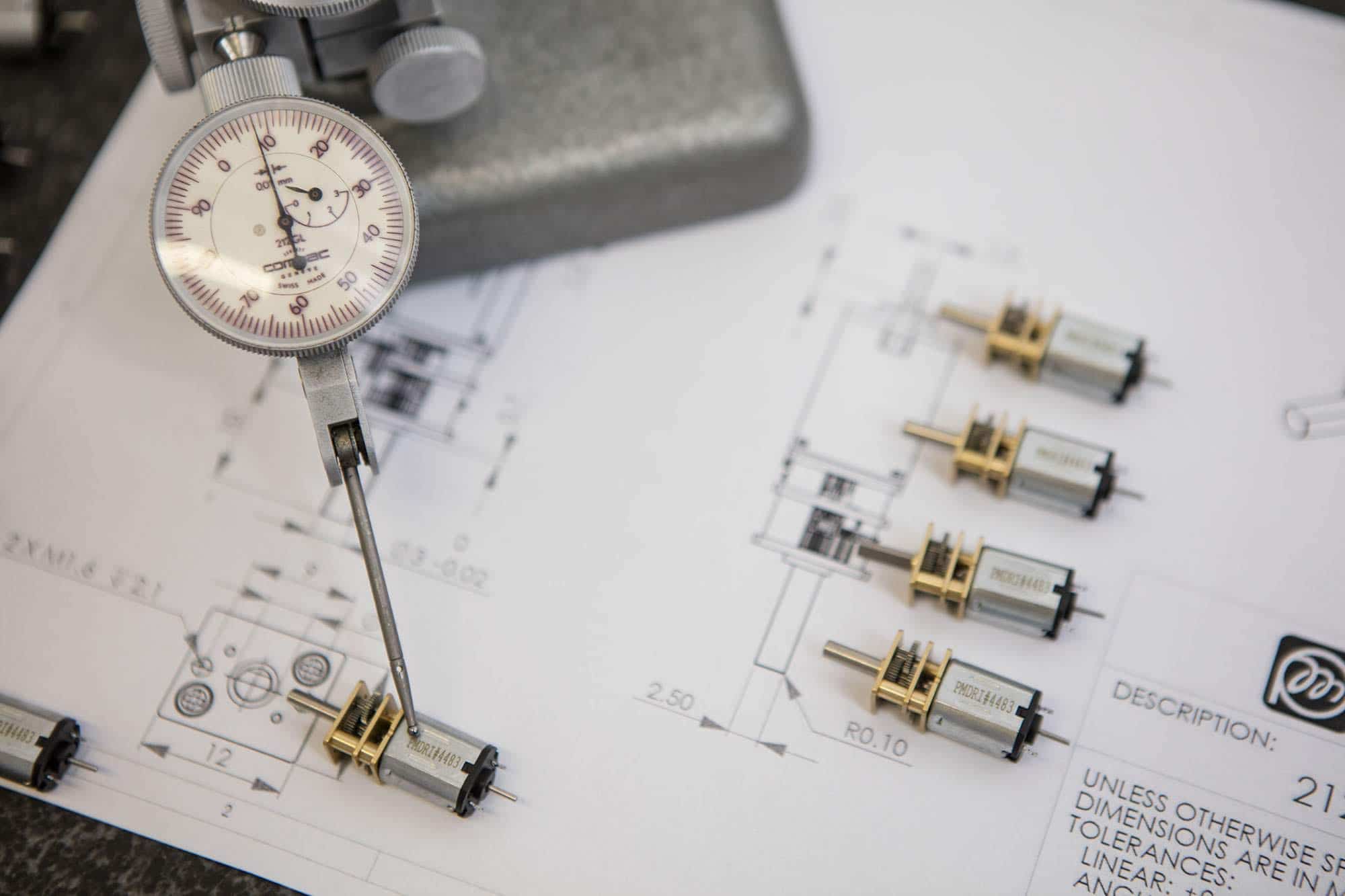

Our processes are engineered to prevent bad surprises

We have built the knowledge, processes, experience and infrastructure to allow us to avoid the design and manufacturing pitfalls that come with designing and mass-producing miniature motors and mechanisms in Asia. We can help you access lower costs whilst covering your back.

Speak to our team

Speak to our team of specialist motor, mechanism and motion control engineers.

Let us help you realise your project into mass production, with minimised design and production risks.

THE PRECISION MICRODRIVES ADVANTAGE

How can we help?

Custom assemblies

Longevity testing

Mechanism design

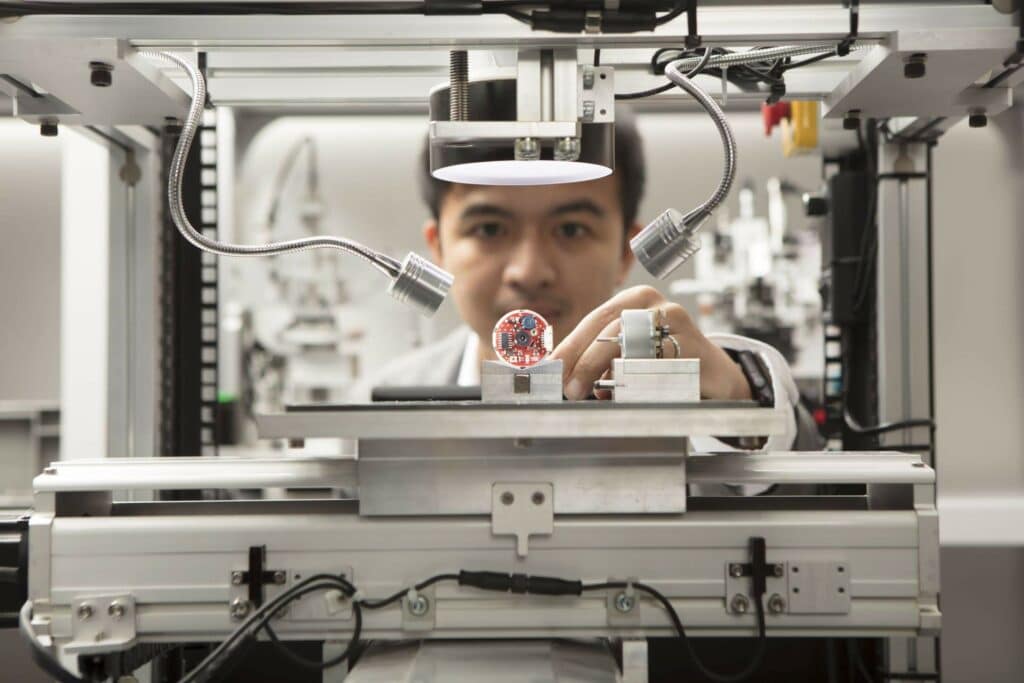

Engineering confidence

In-house production

Full testing validation

WHERE WE DELIVER VALUE

We can add value to your product irrespective of industry or location

Industries served

We provide motor and mechanism solutions to all sorts of industries, including:

Medical

Cost-effective customised application solutions designed with precision to fit the fast-paced medical industry.

Instruments

Motors and customised mechanisms for a wide range of measuring instruments with precision.

Industrial

Solutions for complex industrial machines aiding in a wide range of functions.

Consumer

Everyday consumer applications containing a plethora of miniature motors and mechanisms.

Security

Dependable motor mechanism products to keep you protected and secure

Healthcare

Reliable and cost-effective micro motors and mechanisms built for dependable and innovative healthcare devices.

Global engineering

Precision Microdrives serves customers worldwide with unique time zone positioning. This means that we can talk to our customers in their language, avoiding miscommunications. With offices in London and Hong Kong, we have the capability to support customers directly across the world daily.

Our main markets:

- USA

- UK

- Germany

- France

- Northern Europe

- Israel

- Singapore

- Taiwan

- Japan

- China

Application examples

Bench-top pill counting machine

A bench-top medical instrument used a vibration motor to aid the movement of pills through instrument pathways.

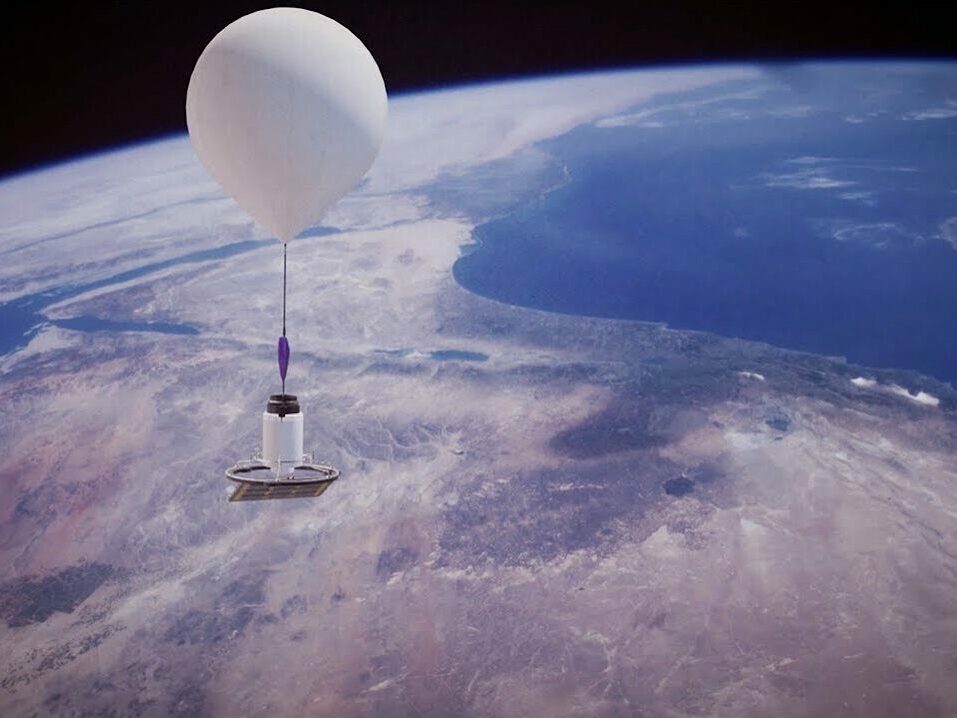

Weather balloon measurement lab

High volumes of low-cost reliable single-use motors for weather balloon measurement lab.

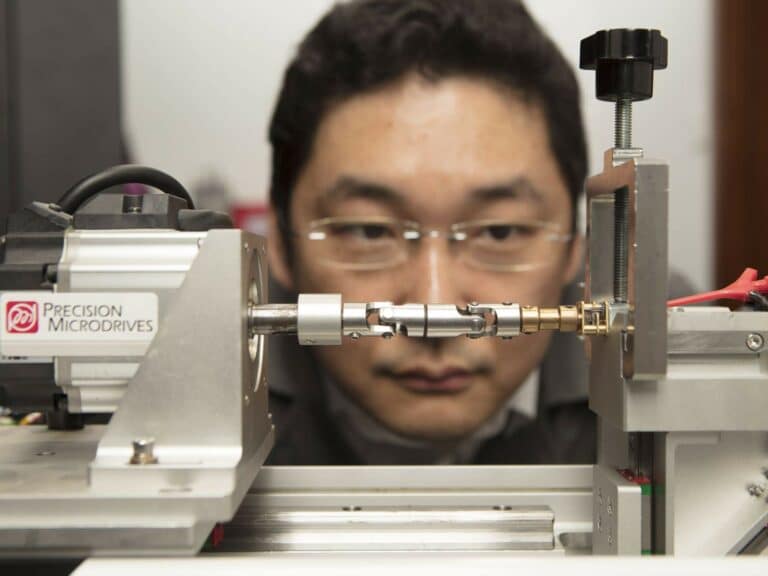

Swarm robot research linear actuator

Challenging technical and unique application for swarm robotics for a European robotic research Institution.

Pacemaker

Everyday consumer applications containing a plethora of miniature motors and mechanisms.

Smart home

Precision motors for solar-powered, smart-enabled motorised control access system for operating home devices like locks, windows and blinds.Solutions for complex industrial machines aiding in a wide range of functions.

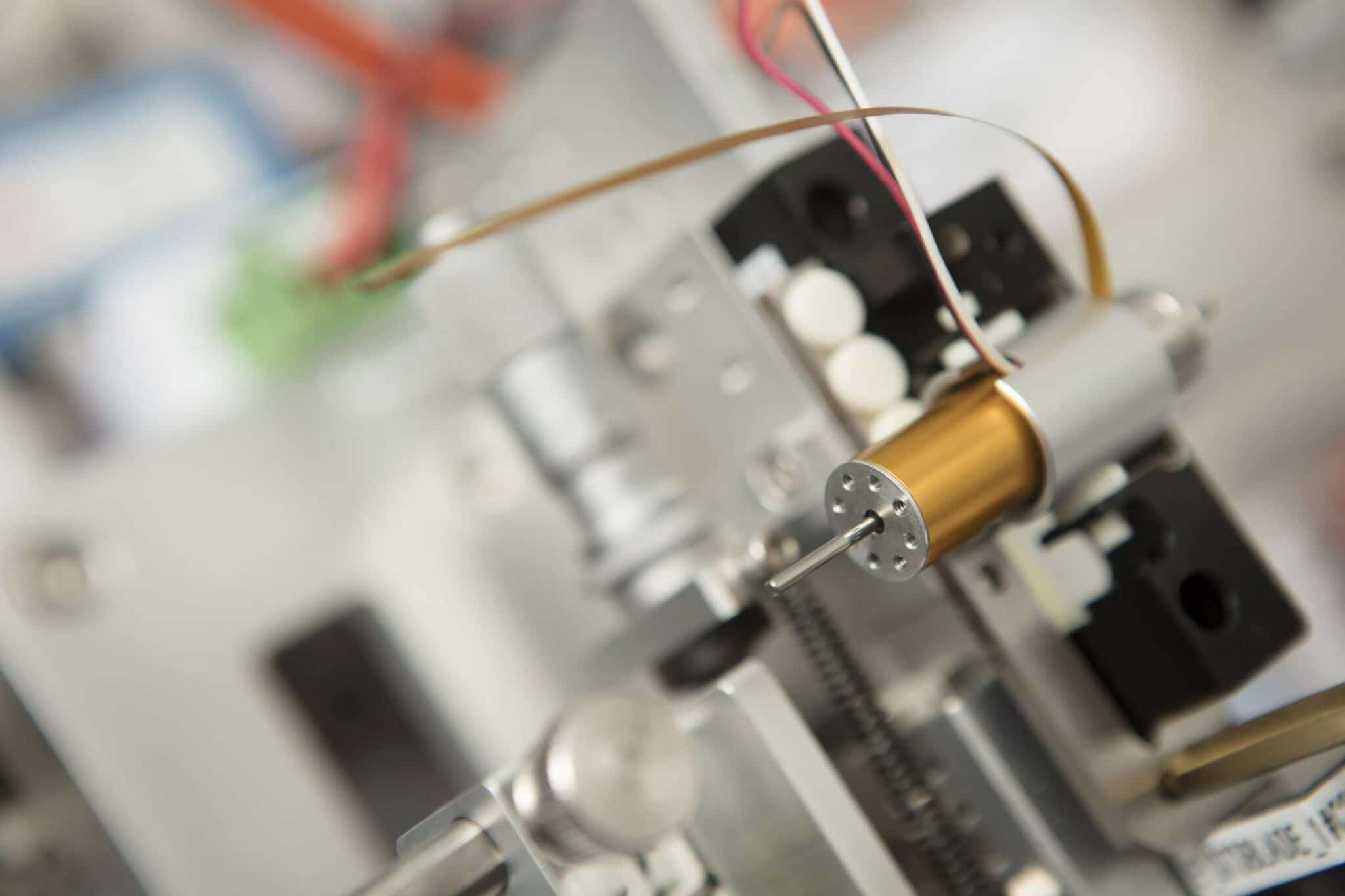

Handheld water analysis device

Handheld water spectrophotometry analysis instrument required a 4mm micro DC motor used to rotate the miniature mirror plate. Motors and customised mechanisms for a wide range of measuring instruments with precision.

HOW WE DELIVER VALUE

How we deliver outstanding results for our customers, every time

OUR PRODUCTS

What we deliver

-

Brushless Motors

We offer a comprehensive range of DC brushless motors in both slotted and slotless (high torque and negligible cogging) designs,

View Page

-

DC motors

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf

View Page

-

DC gear motors

Building on our range of DC motors, we integrate spur and planetary gearboxes, from 6mm to 60mm frame diameters.

View Page

-

Mechanisms

Custom motor assemblies designed and manufactured to your requirements. A turnkey service from design inputs to mass production.

View Page

-

Vibration motors

With every vibration and haptic technology covered, we’ll help you select the best vibrating solution for your application.

View Page

-

Linear actuators

Precise, reliable and highly customisable linear actuators designed for a wide range of industrial, commercial and medical applications.

View Page

OUR ADVANTAGE

Working with Precision Microdrives

Our clients

Our clients are designing a new product or undertaking a lifecycle refresh of an existing one. They are using the opportunity to embrace value-engineering instead of over-engineering.

This doesn’t mean low standards. Instead, our clients are developing a specification with care, designing and manufacturing with diligence and delivering precisely.

Our motors and mechanisms are fit for world-class products at a price that enables straightforward commercial success.

Our vision

Like the products themselves, a motor and mechanism manufacturer has many moving parts. The technology, whilst mature, is still complicated and underpinned by many engineering disciplines.

We offer technical support, guidance and a real partnership to innovators who want to manage and reduce their risk and maximise commercial success.

Founded in 2004 to make sourcing of proven electro-mechanical mechanisms in Asia easier and more reliable, our business is built on a desire to help like-minded people use miniature motors in their application.

Our objective

The more you embrace a partnership with us the more value and commercial success we can bring to your business.

We can take on the design and manufacture of your application’s electromechanical mechanism with significant experience. We can save you from the pitfalls and risks in working with these types of products. We can integrate modern and proven technology in highly cost-effective packages.

This will help you focus on developing the technology and features that will set your application apart from your competition. The more we can help you focus on maximising your value the more we prosper together as partners.

MECHANISM DESIGN PARTNER

Far more than your average motor supplier

We use our proven technology to solve your motor problems, reducing costs and managing your risk through optimised design.

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.

Case studies

View our past projects with examples of various different applications utilising custom-made motor and mechanism solutions from Precision Microdrives.