Case study

Orthodontic tooth re-aligning device

- Electronic orthodontic tooth re-aligning device designed to be used alongside braces.

- Coin vibration motor used to stimulate the movement of the teeth and reduce the time needed in braces.

- The customer had a short ramp-up time (10k to 100k motors in three months).

Challenge

- Our customer approached us at the end of 2019 when they were looking for a reliable coin vibration motor supplier who could ramp up motor supplies as they were needed.

- All the design work had been completed before they contacted us so we were unable to suggest any improvements to the device functionality.

- A contract manufacturer (CM) was brought in to manage the project once the device had been fully qualified and signed off.

- The delivery times had also been agreed upon with the final customer before the CM came and spoke with us.

Solution

- We were able to supply them with a small but reliable coin vibration motor that would drop into the product without the need to redesign any of the housing or the tooling.

- Our Hong Kong engineering team managed to expedite the sign-off of the motors and their production in a much shorter time frame than was originally planned.

- The demand went from 10k to 100K motors within three months.

Results

- The teeth re-alignment device was launched into the dental market as planned and just ahead of the global pandemic. It was extremely well received by both orthodontists and patients, as it reduced the number of in-person visits a patient needed to attend.

- PMD was able to supply the CM with the motor volumes they had signed off with the end customer so there was no risk of their production line having to pause due to being short of parts.

- Due to our efficiency in getting this device to market, they have asked us to support them with a new project.

Project scope

Orthodontic vibration tooth moving device used in conjunction with a brace

Our customer reached out to us at the end of 2019 with the design for a new orthodontic tooth re-alignment device designed to be used for five minutes a day, in conjunction with a brace. The aim of the device was to help stimulate the relocation/re-alignment of the teeth and reduce the discomfort to the user. It would also reduce the length of time a brace would need to be worn, speed up treatment times and reduce the number of in-person appointments needed.

Through the discussions we had with the customer we discovered that the design work had been carried out by a small design firm and then handed over to our customer, the Contract Manufacturer (CM). The CM was only responsible for getting the device into full production and ensuring it was launched on the scheduled date.

The device was already in production in China but the end customer was experiencing quality and supply issues with their current CM. This meant they were looking for a second source supplier and it also explained why our customer had been onboarded just as the device was about to go into full production.

The CM had also committed to an agreed monthly volume with the end customer which was signed off quite late in the project, just before we were planning to ramp up production. Fortunately, we were able to expedite their signed-off order and the subsequent production needs to meet their deadline. Our team managed to turn around 5x their originally agreed annual supply within just three months.

STAGE 1

Designing for application

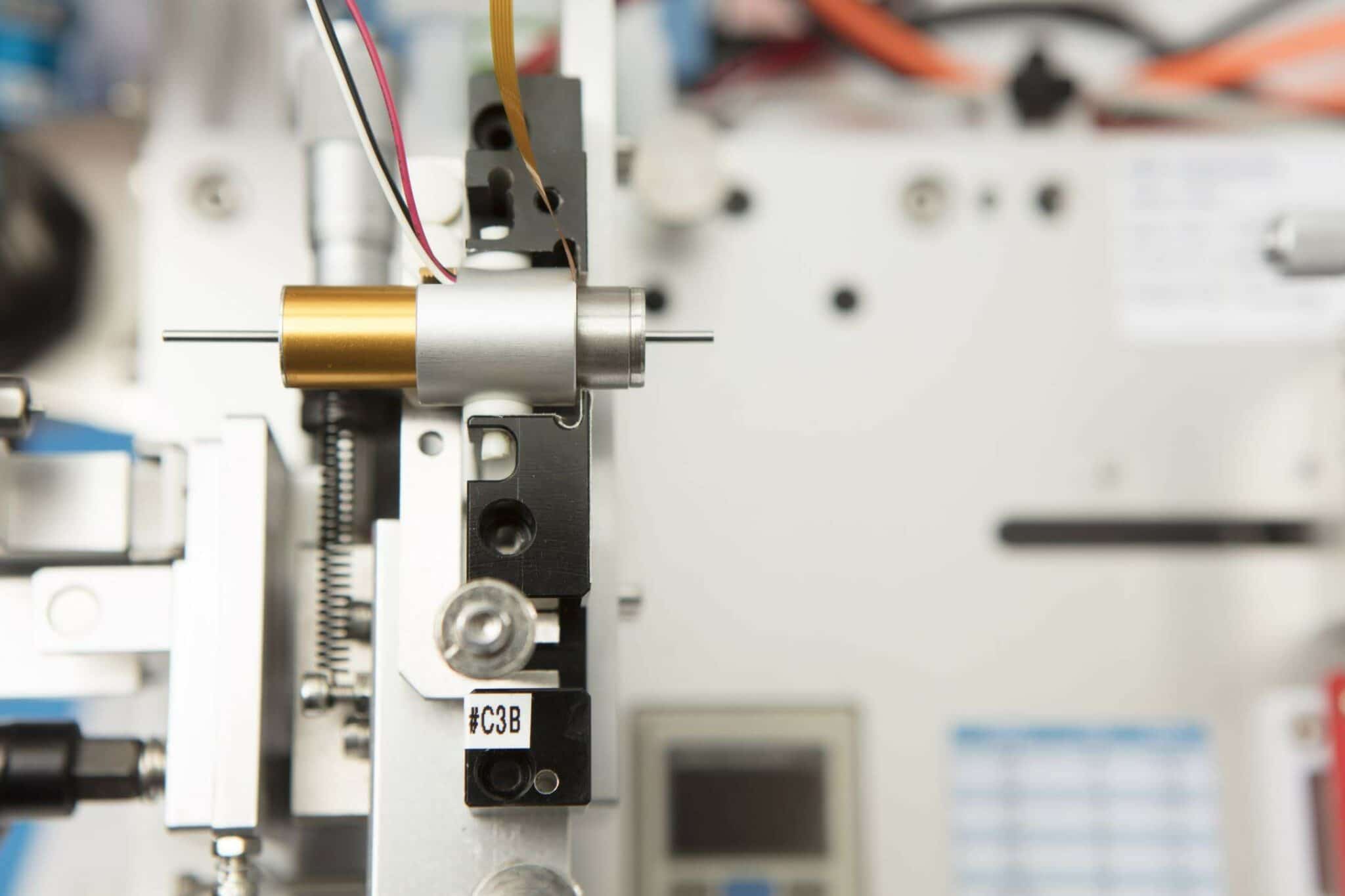

- Our customer was looking for a small but powerful and reliable coin vibration motor that could be dropped into the device without the need for any changes to the design.

- All the device design work had been completed and signed off before they approached us so we were unable to make any suggestions on how to improve any of its functionality.

- It transpired that they had been working with samples from another supplier but were experiencing quality and supply issues. This meant they were looking for a new second source supplier.

STAGE 2

Manufacturing and testing

- They had a clear specification for the strength of the motor they were looking for and the dimensions of how large it could be due to all the design work having been already completed.

- Samples of our recommended Precision Microdrives coin vibration motor was tested to check the performance requirements would be met, including the lifetime to ensure it would be suitable for the device.

- Our customer ramped up more quickly than we expected, but we were able to supply them with their motor requirements without causing any delays to the production line.

STAGE 3

Results and relationship

- The product has been well received in the dental market especially as people are more open to completing treatment in their own homes and not visiting medical professionals. This was particularly popular during the global pandemic.

- We have built a strong relationship with the CM as we have proved we can provide the volume and quality of motors they needed on time and to spec.

- We are now their primary supplier as it transpired they were having quality and supply issues with their original supplier.

CASE STUDIES

We supply motor and mechanism solutions for all sorts of applications

-

Medical patient simulator

Patient simulator for first-aid cardiac arrest training required a vibration motor to haptic simulate a heartbeat.

View Case Study

-

Swarm robot research linear actuator

Challenging technical and unique application for swarm robotics for a European robotic research Institution.

View Case Study

-

Bench-top pill counting machine

Bench-top medical instrument used a vibration motor to aid movement of pills through instrument pathways.

View Case Study

-

Weather balloon measurement lab

High volumes of low-cost reliable single-use motors for weather balloon measurement lab.

View Case Study

-

Emergency services ruggedised radio

Emergency radios to withstand high temperatures, impacts, and vibrate through protective clothing

View Case Study

-

Surgically implanted pacemaker motor

Brushless vibration motor within a FDA Class III implanted medical pacemaker device.

View Case Study

MORE THAN YOUR AVERAGE MOTOR SUPPLIER

We manage your risk

We manage your risk through optimised design and rigorous testing, protecting your application and intellectual property, and fulfilling your performance requirements, whilst reducing your lifecycle costs.

MOTORS & MECHANISMS

Precision products

From off the shelf motor components to fully validated and tested complex mechanisms, choose a motor and mechanism partner you can trust.

-

DC motors

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf

View Page

-

DC gear motors

Building on our range of DC motors, we integrate spur and planetary gearboxes, from 6mm to 60mm frame diameters.

View Page

-

Vibration motors

With every vibration and haptic technology covered, we’ll help you select the best vibrating solution for your application.

View Page

-

Haptic feedback

Practical and reliable, low noise and high quality haptic feedback solutions for all types of application user interface.

View Page

-

Mechanisms

Custom motor assemblies designed and manufactured to your requirements. A turnkey service from design inputs to mass production.

View Page

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies

Industries we serve

At Precision Microdrives we design and manufacture customised electric motors and mechanisms across a number of industries.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help.