Case study

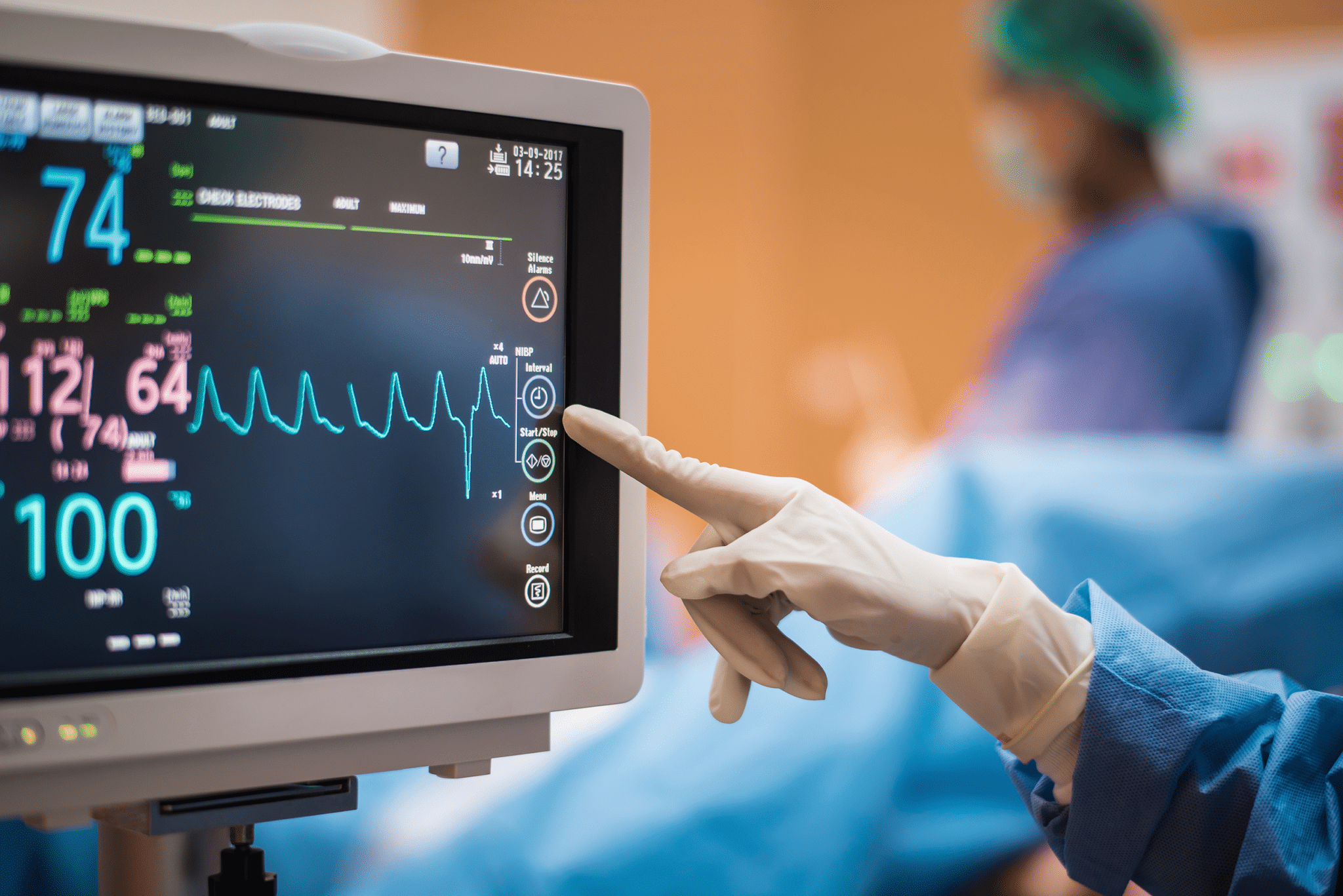

Touchscreen ECG monitor

- Touchscreen ECG monitor with integrated haptic feedback to provide a crisp ‘button pressing’ sensation when used.

- Precision Microdrives supported the customer from initial development through to mass production.

- 10mm LRA vibration motor with a low EMI (Electromagnetic Interference) rating.

Challenge

- Our customer had designed a new portable ECG monitor, and wanted to add haptic feedback to the coloured touchscreen display. This would allow medical professionals to receive the same button press sensation when they use the monitor, as when they used the dedicated keypad on the control panel.

- They had limited knowledge of how haptic feedback technology works so were struggling to successfully integrate haptics into the device.

- Our customers’ key concern was mitigating the risk of the motor interfering with the ECG’s ability to pick up the rhythm and electrical signals produced by a patient.

Solution

- PMD’s team of application engineers reviewed the product specifications, and worked with our customer’s in-house engineering team. We helped support them from the development stage right through, and into mass production.

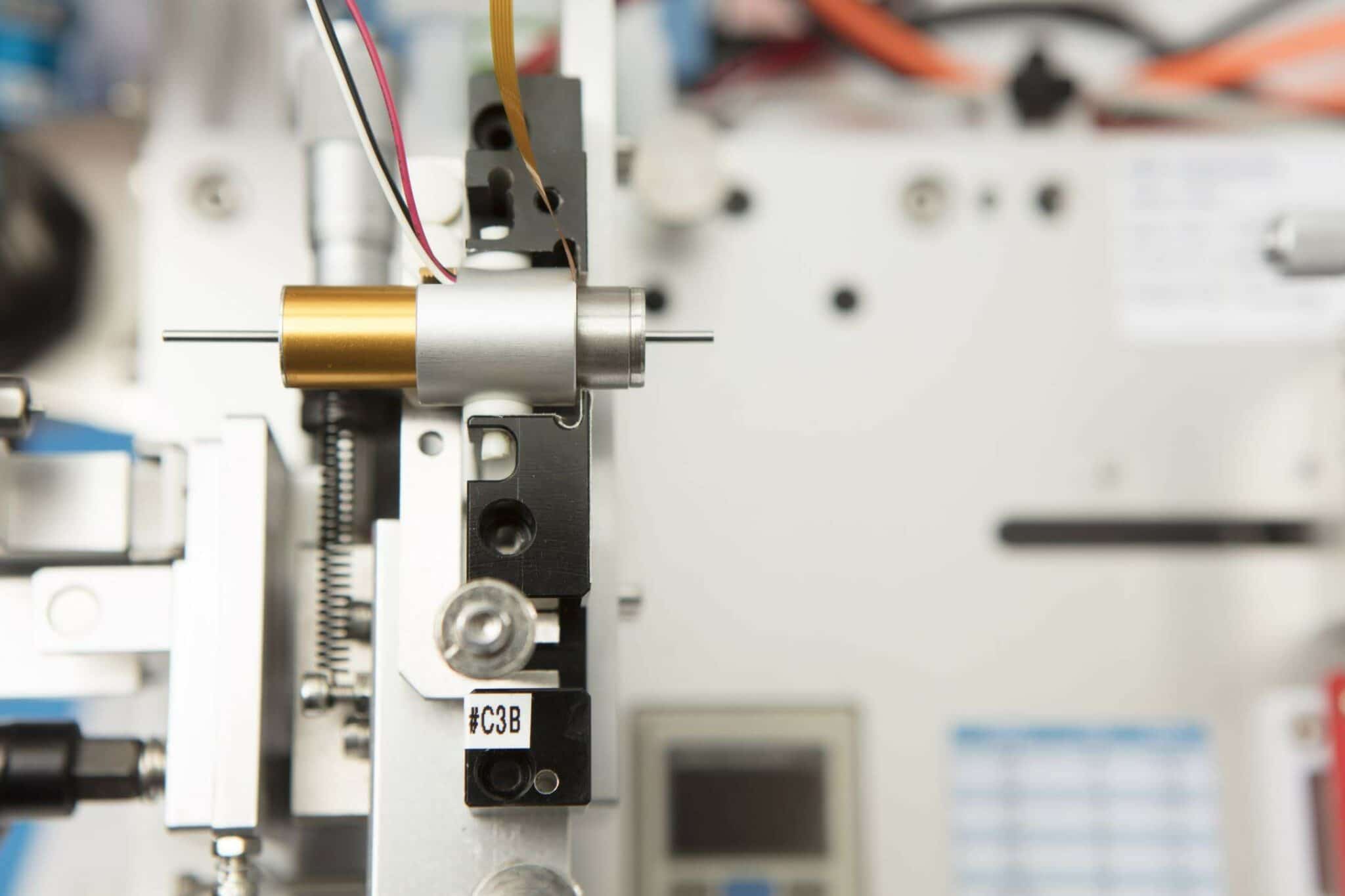

- Our engineering team proposed a 10mm LRA vibration motor as this has a low EMI (Electromagnetic Interference) shadow, and with the correct driver can offer crisp haptic feedback effects.

- We shared the datasheet and our test results for the proposed motor, to prove that it would meet the required EMI rating.

Results

- The product was successfully launched on time and to specification into the European Medical Market. Users liked the addition of haptic feedback on the touchscreen.

- Our customer has had a consistent annual order and Precision Microdrives has supported them to manage their costs by having a flexible call-off annual sales agreement.

- Recently there has been an increase in demand for this device and we were able to support their ramp-up in production, without impacting costs or lead time.

- We have been successfully supplying this customer with our motor solution for over five years.

Project scope

Touchscreen ECG device using haptic feedback to give medical professionals the same sensation as pressing a traditional button

This customer based in Italy reached out to Precision Microdrives as they were designing a new ECG device and wanted to add haptic feedback to the touchscreen. They had bought a selection of vibration motor samples from us, but due to having limited knowledge of how haptic feedback works and its complexities, they were struggling to integrate the technology into their device.

Our application engineering team worked with them to provide a large amount of technical support and know-how during the development stage of the project. This enabled their in-house engineering team to correctly generate the clear, crisp haptic sensation they wanted to create for the touchscreen.

The device was initially soft-launched into the European medical market and was well received. Since then, our customer has had a consistent yearly order with flexible call-offs, plus a few ramp-ups in production that PMD has supported, allowing them to maintain a constant supply of monitors to the market.

STAGE 1

Designing for application

- We supported our customer throughout the design process and provided them with a large amount of technical support.

- This enabled them to overcome the difficulties they were having adding the haptic feedback sensations they wanted.

- The customer had concerns about the level of EMI (ElectroMagnetic Interference) that the motor would transmit when the monitor was being used. We presented a 10mm LRA vibration motor as the solution.

STAGE 2

Manufacturing and testing

- The vibration motor was successfully tested to prove the EMI rating was sufficiently low enough not to interfere with the main function of the ECG monitor.

- The device was thoroughly tested and validated, to ensure it would perform as needed before it was signed off and went into full mass production.

- Our detailed support work enabled them to launch an innovative product that allows medical professionals to provide more accurate results to patients.

STAGE 3

Results and relationship

- We were able to support the customer from the development stage through to mass production and this saved their engineering team considerable R&D work.

- Due to the level of technical support, we provided the customer they decided that they would make us their sole supplier for the LRA vibration motor for this device.

- By agreeing to a yearly order commitment we have proactively managed their risk, helped them ramp up their production and reduced their supply costs.

CASE STUDIES

We supply motor and mechanism solutions for all sorts of applications

-

Medical inhaled medication delivery device

Intelligent medical inhaler device, which was FDA Class III approved, required a gear motor mechanism to provide precise

View Case Study

-

Medical patient simulator

Patient simulator for first-aid cardiac arrest training required a vibration motor to haptic simulate a heartbeat.

View Case Study

-

Swarm robot research linear actuator

Challenging technical and unique application for swarm robotics for a European robotic research Institution.

View Case Study

-

Bench-top pill counting machine

Bench-top medical instrument used a vibration motor to aid movement of pills through instrument pathways.

View Case Study

-

Weather balloon measurement lab

High volumes of low-cost reliable single-use motors for weather balloon measurement lab.

View Case Study

-

Surgically implanted pacemaker motor

Brushless vibration motor within a FDA Class III implanted medical pacemaker device.

View Case Study

More than your average motor supplier

We manage your risk

We manage your risk through optimised design and rigorous testing, protecting your application and intellectual property, fulfilling your performance requirements, whilst reducing your lifecycle costs.

MOTORS & MECHANISMS

Precision products

-

DC motors

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf

View Page

-

DC gear motors

Building on our range of DC motors, we integrate spur and planetary gearboxes, from 6mm to 60mm frame diameters.

View Page

-

Vibration motors

With every vibration and haptic technology covered, we’ll help you select the best vibrating solution for your application.

View Page

-

Haptic feedback

Practical and reliable, low noise and high quality haptic feedback solutions for all types of application user interface.

View Page

-

Mechanisms

Custom motor assemblies designed and manufactured to your requirements. A turnkey service from design inputs to mass production.

View Page

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies

Industries we serve

At Precision Microdrives we design and manufacture customised electric motors and mechanisms across a number of industries.

About PMD

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help.