Case study

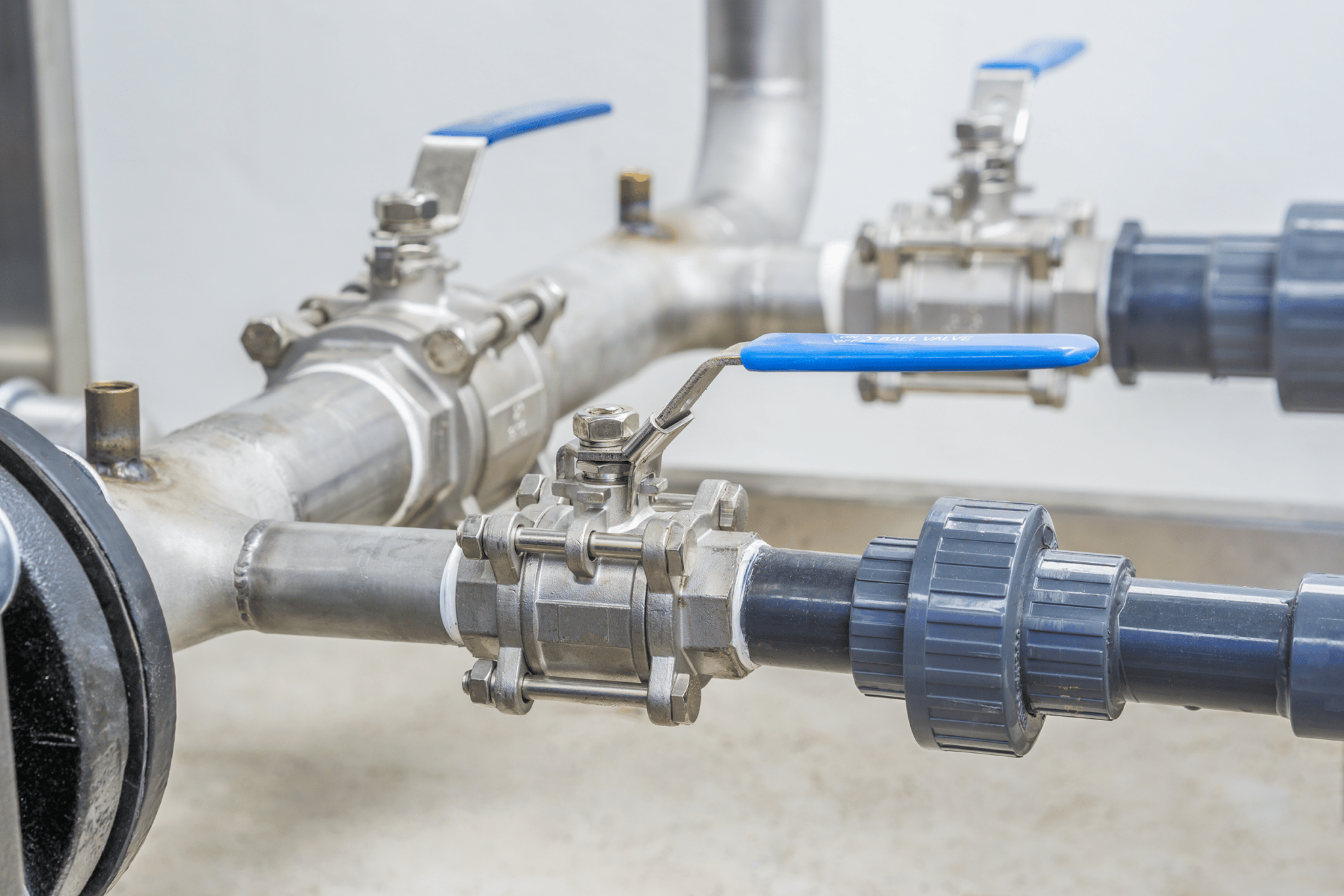

Electronic powered water ball valve

- Remotely operated electronic water ball valve used in isolated areas of the world.

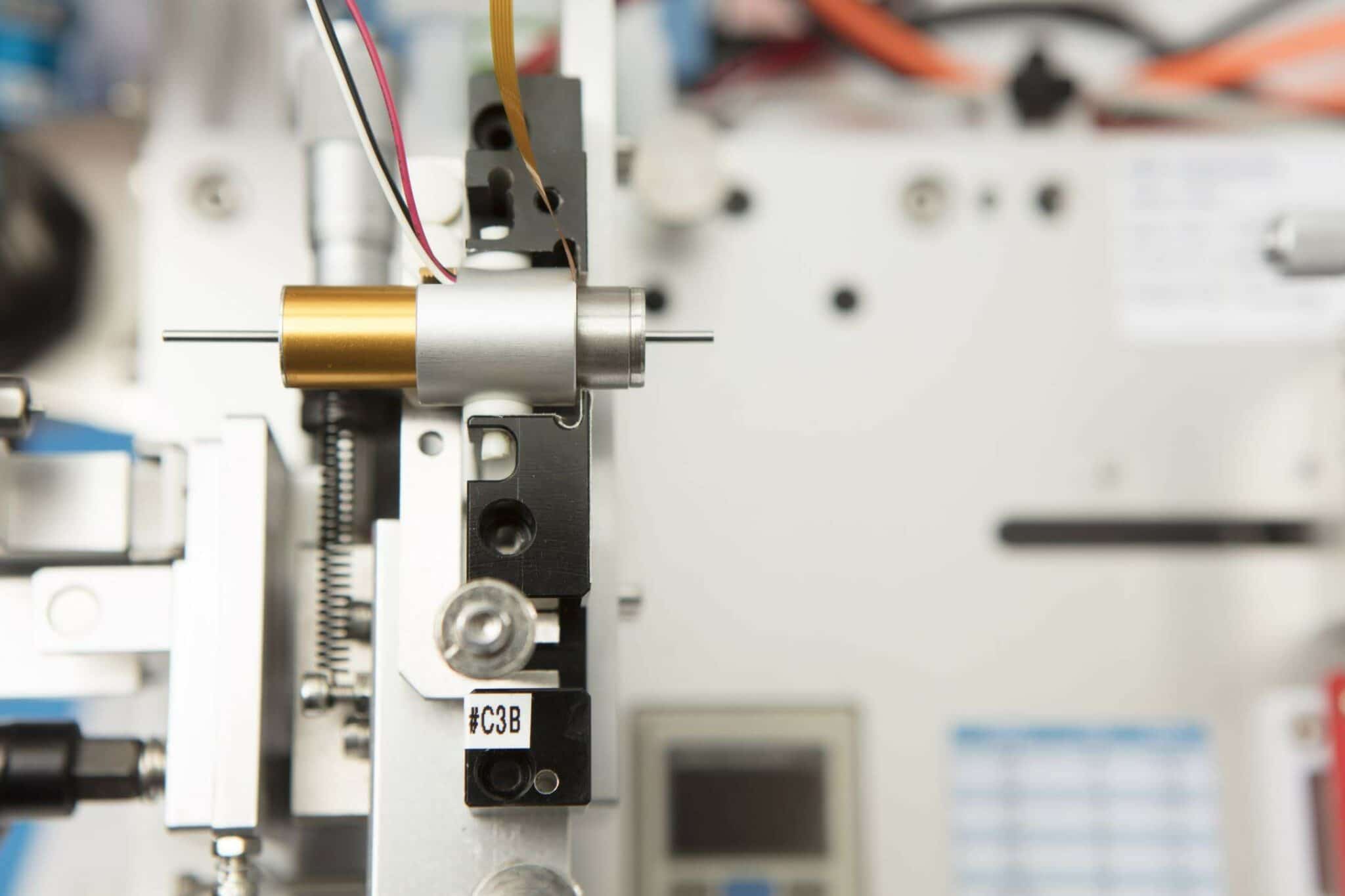

- Gearmotor used to remotely open/close the values as needed.

- 16mm Gearmotor used to operate the valve mechanism.

Challenge

- Our customer approached us as they had designed a new electronically-actuated water ball valve, and needed support with the design and specification of a suitable gearmotor.

- They came to us with a built prototype / POC (Proof of Concept), but they had concerns with the axial and radial loading that the gear motor would experience.

- The gear motor needed to be powerful, robust, and reliable as it was to be used in a wide variety of environments and harsh locations. Some of these would be subjected to extreme weather conditions.

- The motor needed to have enough torque to operate the valve whilst consuming moderate power given that it was a battery power device.

Solution

- Precision Microdrives’ team of UK based application engineers reviewed the customer’s prototype. They then worked with them to fully understand the technology options and performance demands they had.

- Meanwhile, our Hong Kong based manufacturing engineers ran detailed in-house tests on the proposed gearmotors, to ensure they had enough torque, low enough power consumption, and longevity, in a range of environmental conditions.

- The customer also thoroughly tested the gearmotors in both dry, wet, hot and cold environments to ensure they would perform reliably in the field. They also ran tests to check the Environmental, IP (Ingress Protection) against dust and moisture and longevity, in application.

- While testing in application, the customer suffered some earlier than expected motor failures. We investigated and recommended modifications to their design to prevent driving the motor into a hard end-stop (never a recommended design approach!).

Results

- The product has just been successfully launched into the market, and has been well received.

- Due to our engineering team spending time fully understanding the technology used by the customer, we were able to quickly diagnose and resolve issues during the customer’s development process.

- We supplied a high level of support, and as such our customer has asked us to work with them on the development of a new flow measuring water meter.

- Our customer has also committed to a long term purchase agreement allowing us to offer a better unit price. Plus, as they are now using the same motor solution for two projects, they can combine volume, and shipments, reducing further their production costs.

Project scope

Electronic powered ball valve

Our customer approached us with their prototype/POC (Proof of Concept) for a remotely operated electronically-actuated ball valve. They wanted the device to be used in remote locations around the world, and they were looking for a robust and reliable battery-powered gearmotor that consumed low currents, but offered enough torque to open and close the valves as needed. The gearmotor mechanism would need to be able to work in a variety of harsh environments including extreme hot and cold situations.

Precision Microdrives UK based engineers worked with our customer to generate the correct specification and design the most appropriate gearmotor. Meanwhile, our Hong Kong based engineering team thoroughly tested the proposed mechanism to ensure that it met all the customer’s requirements and specifications. Our customer then carried out their own internal detailed test, that included using it in all likely environments. The motor passed these tests, and was then sent for test in some of the actual field locations.

During in-the-field testing, our customer discovered that some of the motors were failing earlier than expected. We carried out a full and detailed investigation of the motors and application, and discovered that the customer’s mechanism was subjecting the motors unreasonably high loads at the end-stop of actuation. We made recommendations for how they could modify their design and this resolved the issue.

After the modification was made, the valves were returned to the field for further testing, passed, and have now been successfully launched into the market.

STAGE 1

Designing for application

- Our customer had prototyped a new electronic ball value for water pipes in remote countries, with harsh environments. They wanted us to support them with getting the device into production and onto the market.

- We worked with the customer to fully understand their technology, so we could design a suitable gearmotor mechanism solution that was strong enough and reliable for the device.

STAGE 2

Manufacturing and testing

- The motors were thoroughly tested by both ourselves and the customer in a wide range of environmental conditions for both performance and longevity.

- We were able to quickly resolve an issue that came up as part of the in-field testing, and this has saved the customer the risk of damage to their brand reputation.

STAGE 3

Results and relationship

- By agreeing to a yearly order commitment and by combing the volumes for the same motor used in another project, we have proactively managed their risk and reduced some of their supply costs.

- We are now supporting them with the development of a new flow measuring water meter.

CASE STUDIES

We supply motor and mechanism solutions for all sorts of applications

-

Medical inhaled medication delivery device

Intelligent medical inhaler device, which was FDA Class III approved, required a gear motor mechanism to provide precise

View Case Study

-

Medical patient simulator

Patient simulator for first-aid cardiac arrest training required a vibration motor to haptic simulate a heartbeat.

View Case Study

-

Swarm robot research linear actuator

Challenging technical and unique application for swarm robotics for a European robotic research Institution.

View Case Study

-

Bench-top pill counting machine

Bench-top medical instrument used a vibration motor to aid movement of pills through instrument pathways.

View Case Study

-

Weather balloon measurement lab

High volumes of low-cost reliable single-use motors for weather balloon measurement lab.

View Case Study

-

Surgically implanted pacemaker motor

Brushless vibration motor within a FDA Class III implanted medical pacemaker device.

View Case Study

More than your average motor supplier

We manage your risk

We manage your risk through optimised design and rigorous testing, protecting your application and intellectual property, fulfilling your performance requirements, whilst reducing your lifecycle costs.

MOTORS & MECHANISMS

Precision products

-

DC motors

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf

View Page

-

DC gear motors

Building on our range of DC motors, we integrate spur and planetary gearboxes, from 6mm to 60mm frame diameters.

View Page

-

Vibration motors

With every vibration and haptic technology covered, we’ll help you select the best vibrating solution for your application.

View Page

-

Haptic feedback

Practical and reliable, low noise and high quality haptic feedback solutions for all types of application user interface.

View Page

-

Mechanisms

Custom motor assemblies designed and manufactured to your requirements. A turnkey service from design inputs to mass production.

View Page

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies

Industries we serve

At Precision Microdrives we design and manufacture customised electric motors and mechanisms across a number of industries.

About PMD

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help.