Linear Resonant Actuator (LRA) vibration motors

High performance Linear Resonant Actuators (LRAs) for demanding haptic feedback applications.

Our Linear Resonant Actuator (LRA) vibration motors are used in handheld or body worn devices, for vibration alerting and haptic feedback functions. In combination with a suitable driver, they offer precise haptic feedback effects with a long lifetime of operation.

We are trusted experts in the design and development of LRA vibration motors for a wide range of consumer and industrial applications. Contact us for free development support and advice!

Browse Linear Resonant Actuators

Export Data| Product Image | Part Number | Stock Level | LRA Type | Diameter (mm) | Height (mm) | Rated Voltage (V) | Resonant Frequency (Hz) | Typical Current (mA) | Typical Amplitude (G) |

|---|---|---|---|---|---|---|---|---|---|

|

C08-00A

Download Datasheet |

890 | Coin LRA (Y-axis) | 8 | 2.6 | 1.2 | 240 | 28 | 0.7 |

|

C08-005

Download Datasheet |

2518 | Coin LRA (Y-axis) | 8 | 3.3 | 1.8 | 235 | 75 | 1.28 |

|

C10-100

Download Datasheet |

1851 | Coin LRA (Y-axis) | 10 | 3.7 | 2 | 175 | 67 | 1.5 |

|

C12-003

Download Datasheet |

Made to order | Block LRA (Z-axis) | 12 | 2.8 | 2 | 204 | 111 | 1.5 |

Filter products

Using LRA vibration motors

Using LRAs is straight forward, but they require special drive signals to function.

Driving linear resonant actuators / linear vibrators

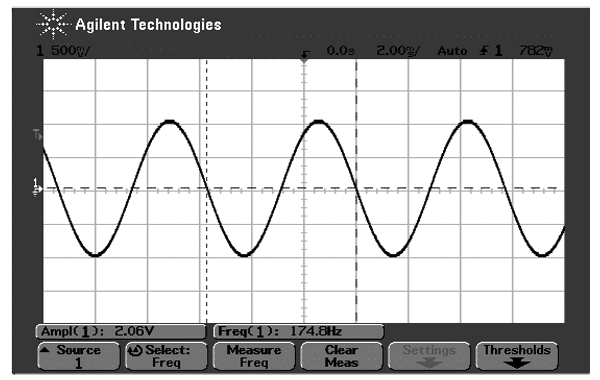

LRA linear vibrators need to be driven with an AC signal, much like a loudspeaker. It is preferable that this signal is a sinewave at the resonant frequency as shown below. Off the shelf driver ICs (such as the DRV2605), which come with integrated haptic feedback patterns, make this task easy.

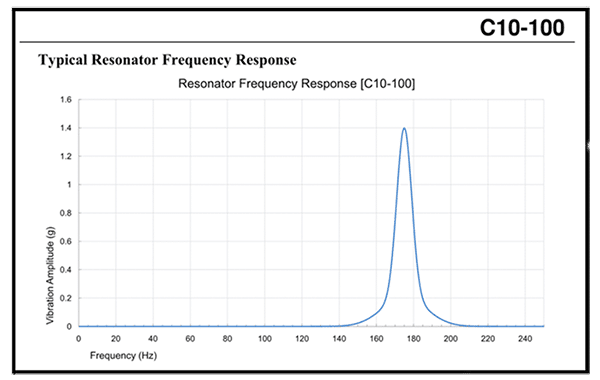

Resonant frequency of operation

LRA vibration motors have a frequency of resonance. The combination of spring stiffness, mass and magnet / coil size, as well as other parameters will dictate the frequency response as shown below. LRA drivers will auto-tune to the resonance point to maximise vibration output.

Extended lifetime for linear LRA vibrators

LRA vibration motors are effectively brushless as they use a voice-coil to drive the mass. This means that the only moving parts that are prone to failure are the springs. These springs are modelled with finite element analysis (FEA) and are operated within their non-fatigue zone.

With little mechanical wear (within normal operating limits), failure modes are restricted to ageing of internal components, which results in much longer MTTF failure modes than traditional brushed eccentric rotating mass (ERM) vibration motors.

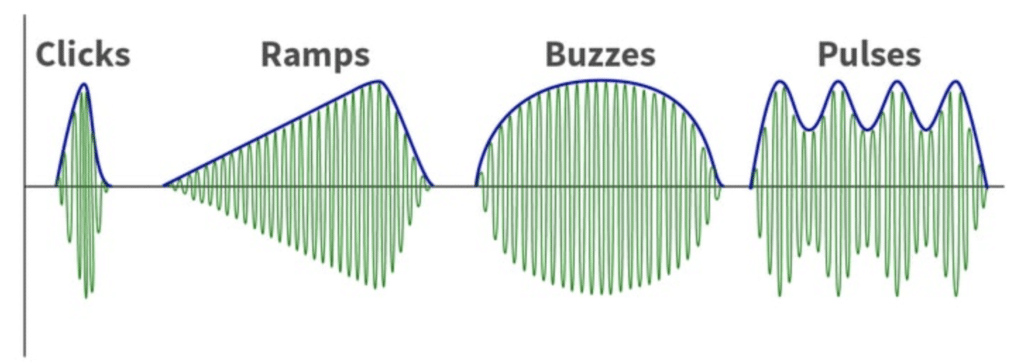

Haptic feedback with LRA vibration motors

Some LRA driver IC’s come with built-in haptic feedback processors, which modulate the sinusoidal vibration to create haptic effects. Below is an example of haptic effects, and how they would be visualised on an oscilloscope.

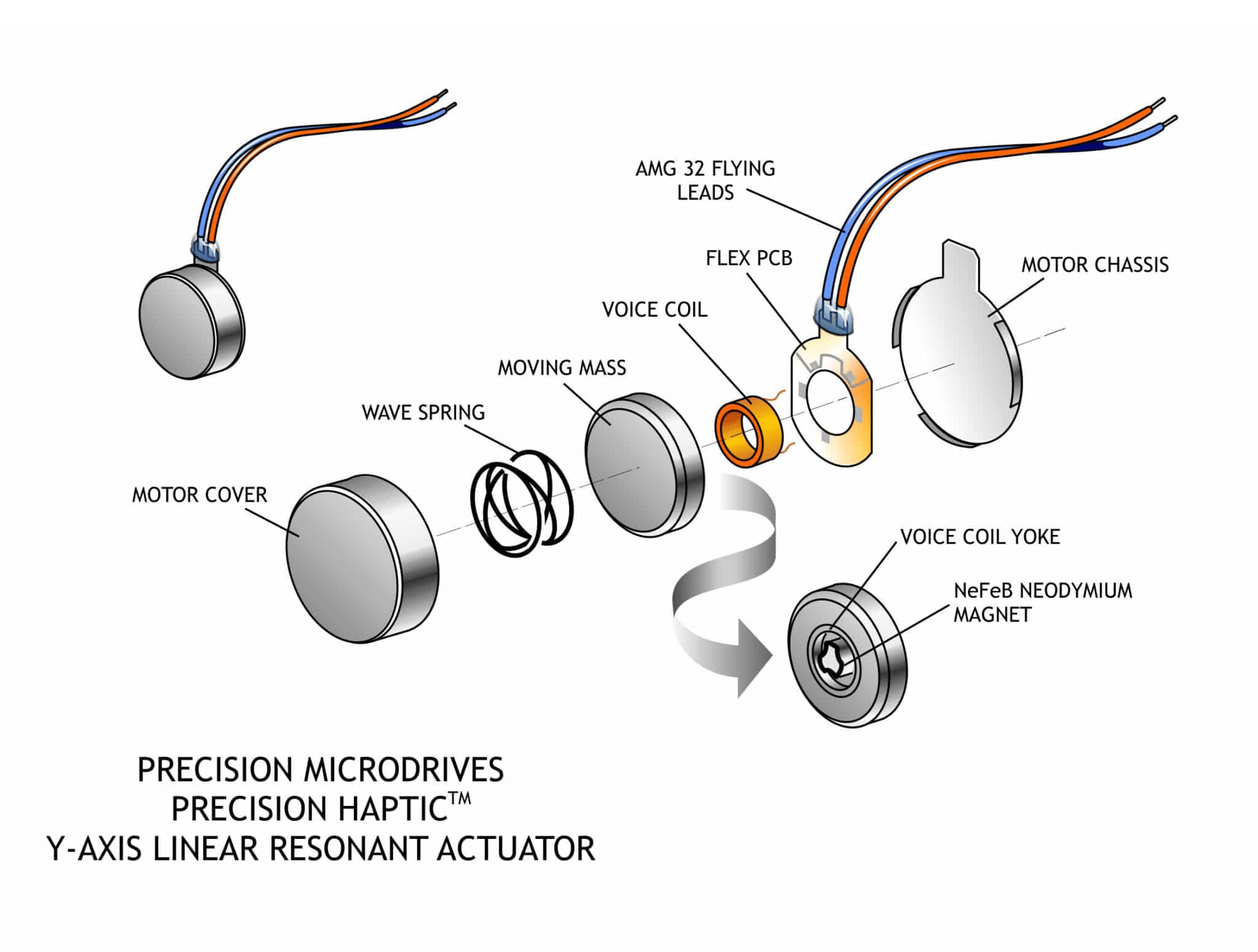

LRA vibration motors construction

Our Linear Resonant Actuator (LRA) vibration motors are used in handheld or body worn devices, for vibration alerting and haptic feedback functions. In combination with a suitable driver, they offer precise haptic feedback effects with a long lifetime of operation.

We are trusted experts in the design and development of LRA vibration motors for a wide range of consumer and industrial applications. Contact us for free development support and advice!

Coil LRA motors : Y-axis vibration

The coin LRA motor is very reminiscent of a loud speaker in design, except that the cone and surround, is replaced with a spring and mass. Vibration goes in and out of the surface onto which the LRA is affixed.

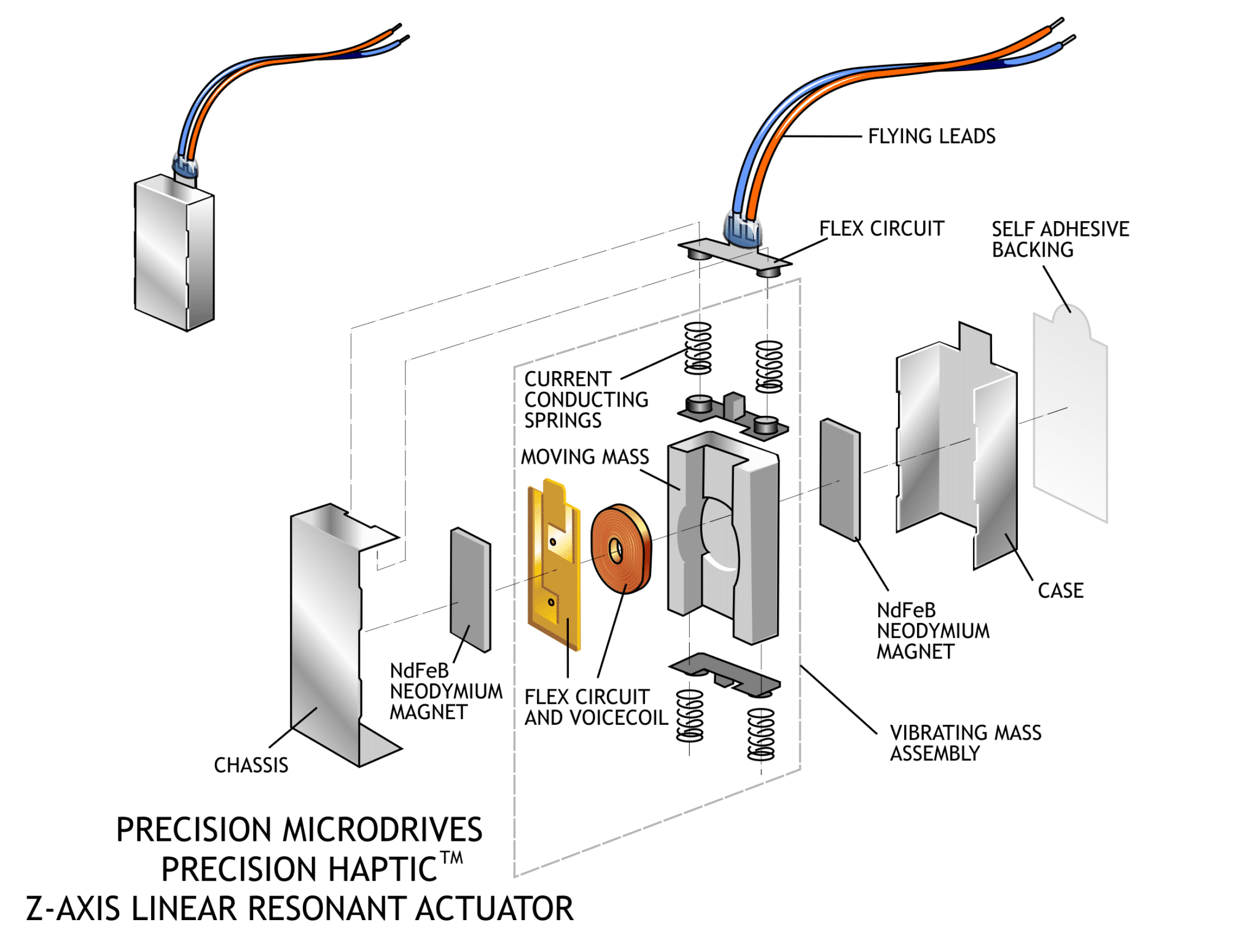

Block LRA motors : Z-axis vibration

The block LRA motor is more reminiscent of a solenoid rotated onto its side, also with a sprung mass. Vibration in this case, is side to side relative to the surface onto which the LRA is affixed.

Technical Resources

Check our application notes, case studies and technical posts on Linear Resonant Actuator LRA motor

- AB-003: Driving Linear Resonance Vibration Actuators

- AB-020 : Understanding Linear Resonant Actuator Characteristics

- Quick LRA Debugging

- When LRA’s don’t behave as expected (Part 1 of 2)

- When LRA’s don’t behave as expected (Part 2 of 2)

- Why Does the Resonant Frequency of an LRA Shift?

- Linear Resonant Actuator Vibration Analysis with Pulse Width Modulated Signals

- Driving LRAs from Audio Signals and Music

- Understanding Horizontal Linear Resonant Actuators

- Haptic feedback for Vape

MORE THAN YOUR AVERAGE MOTOR SUPPLIER

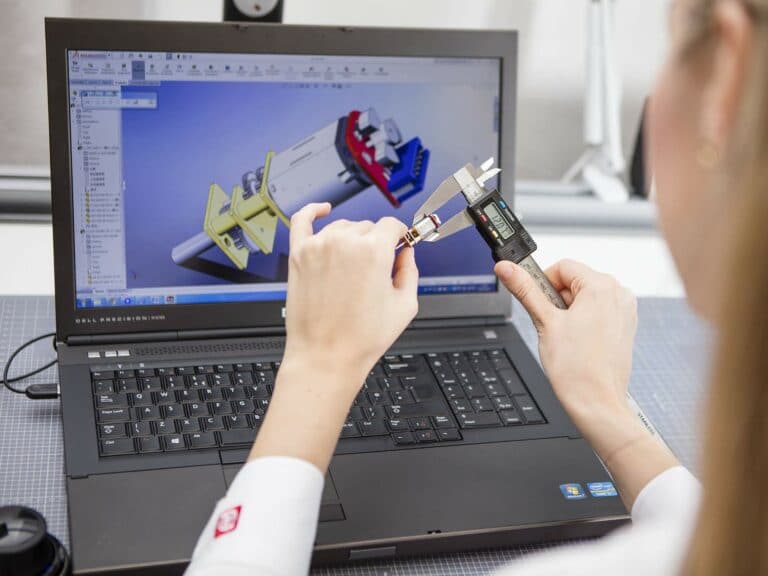

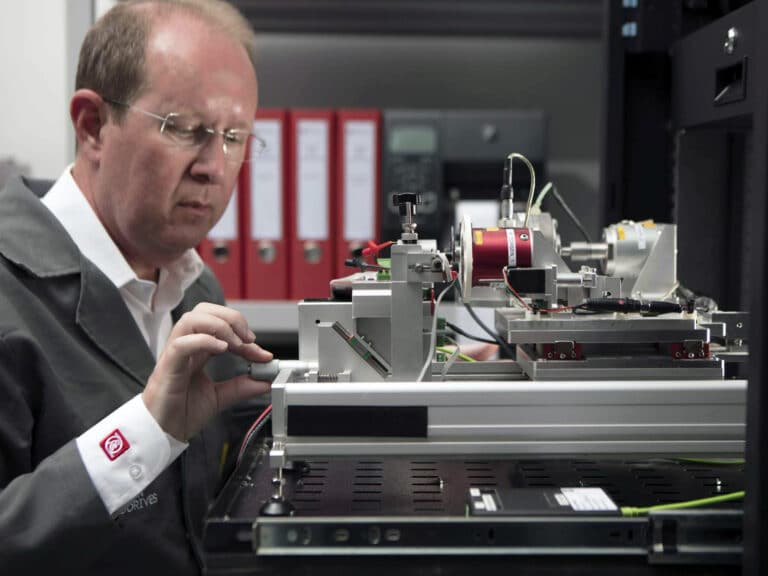

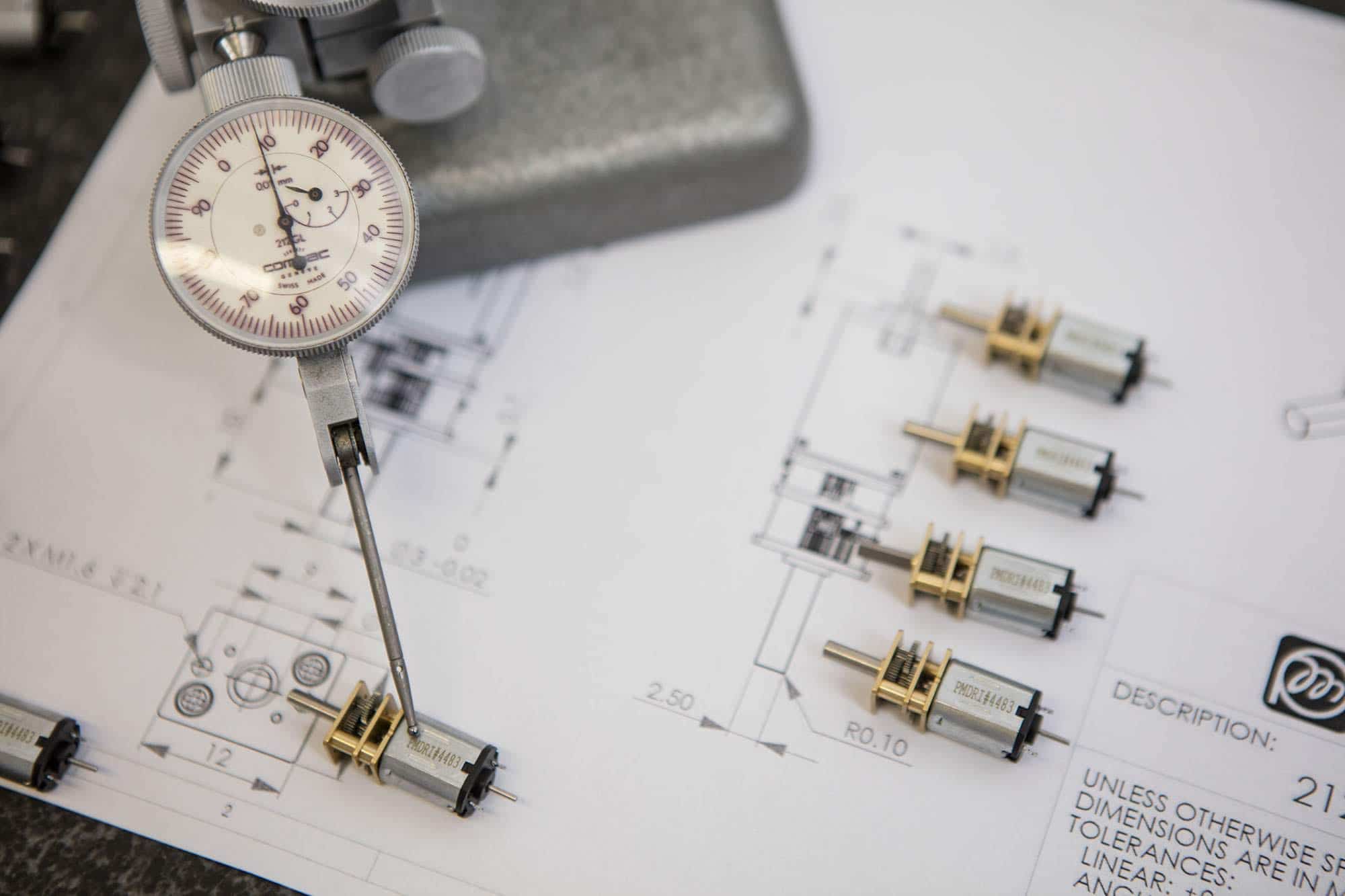

Precision mechanisms

We use our proven technology to solve your motor problems, reducing costs and managing your risk through optimised design.

Specialised engineering services and capabilities

Discover more

Resources and guides

Check our application notes on linear resonant actuator LRA motors

- AB-020 : Understanding Linear Resonant Actuator Characteristics

- AB-003: Driving Linear Resonance Vibration Actuators

- Quick LRA Debugging

- When LRA’s don’t behave as expected (Part 1 of 2)

- When LRA’s don’t behave as expected (Part 2 of 2)

- Why Does the Resonant Frequency of an LRA Shift?

- Linear Resonant Actuator Vibration Analysis with Pulse Width Modulated Signals

- Driving LRAs from Audio Signals and Music

- Understanding Horizontal Linear Resonant Actuators

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.

Case studies

View our past projects with examples of various different applications utilising custom-made motor and mechanism solutions from Precision Microdrives.