Case study

Wearable fall detection aid

- Wrist-worn fall detector/personal alarm for vulnerable people.

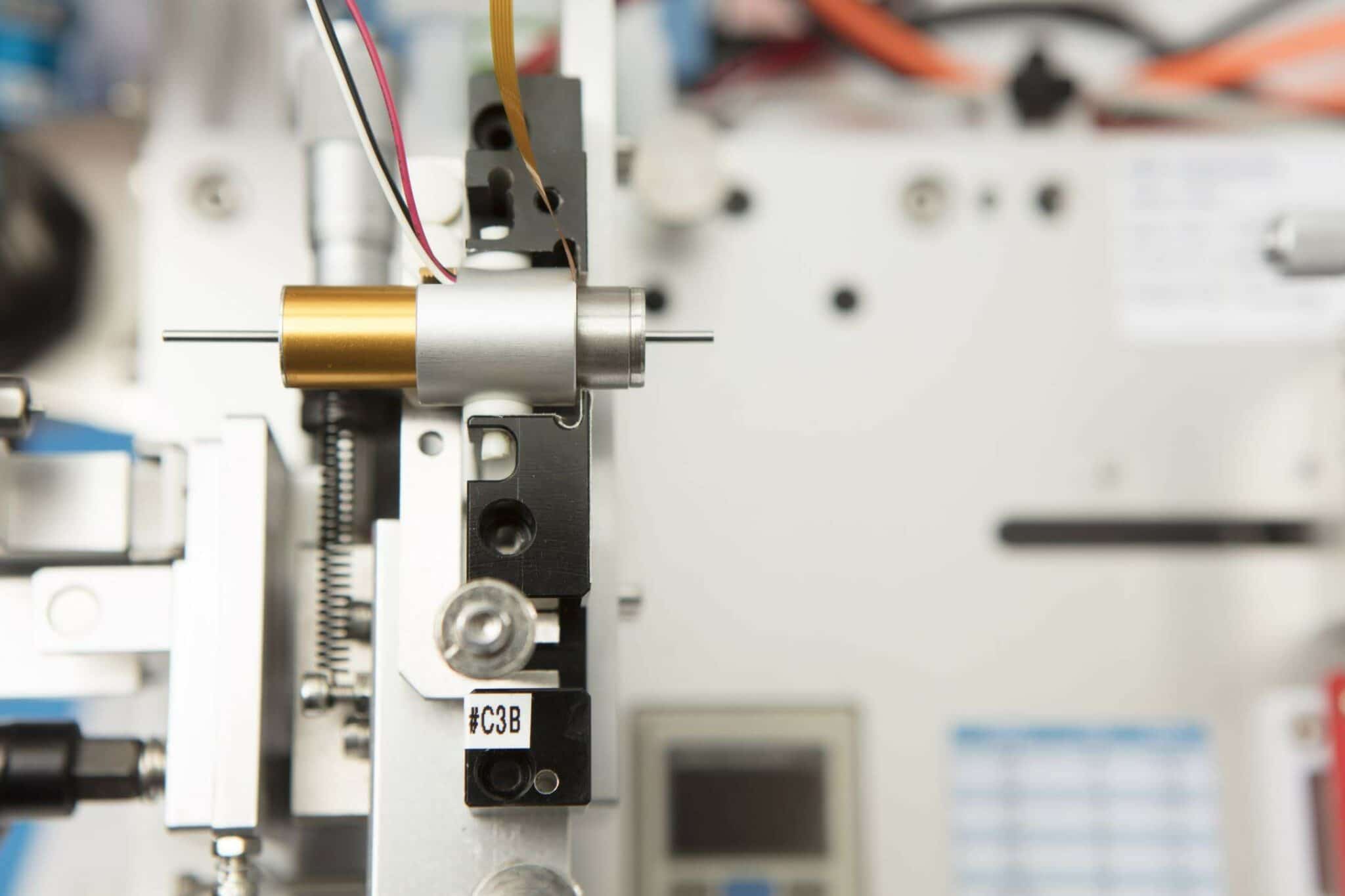

- 10mm coin vibration motor used in the wristband.

- A robust vibration motor used to detect a fall, and connect the wearer to their emergency contacts.

Challenge

- Our customer approached us seeking a powerful and robust coin vibration motor, to integrate into their wearable fall detection aid.

- Low energy drain on the battery was vital along with a long motor lifetime as the device was designed to be worn 24/7 including in the bath/shower.

- They were unable to get any support from an Asian factory due to the small volumes they were looking to purchase.

Solution

- Our UK engineers reviewed their device specification, and discussed their requirements so they understood the needs of the customer.

- Our Hong Kong engineering team evaluated our selection of in-production coin vibration motors to choose the most suitable one.

- We were able to help spec in custom wire sets, as this would speed up the assembly process on the customer’s production line.

Results

- There has been a consistent demand for their wearable fall detection aid since it launched over 10 years ago.

- We have ramped up supply as their demand has increased over the years. They now have a consistent annual order.

- We are now working with them to develop an electronic ankle-worn security tag, that uses the same 10mm coin vibration motor.

Project scope

Wrist-worn fall detection aid for vulnerable people with a risk or history of falling

Our customer approached us while they were designing a new wrist-worn fall detection device that would enable vulnerable people to continue living independently, and with a reduced fear of falling. The device was designed to automatically detect a fall, along with having a push button that the wearer could press. It’s designed to provide the wearer’s family and friends with peace-of-mind as they or the Emergency Monitoring Centre would be instantly notified when a fall occurred.

The device was designed to be worn 24 hours a day, 7 days a week including in the bath/shower. This meant it needed to have a long-lasting and robust motor. The motor also needed to have a low drain on the battery as they wanted to reduce the number of times it needed to be removed for charging.

The customer was struggling to find a motor manufacturer who would supply them with the small volume of motors they were looking to purchase in the begining. They were ideally looking to work with a UK based company as they pride themselves on their ability to design and assembling all their products in the UK.

We worked with the customer and were able to support them with both the motor volume they needed and designed to their specification, a custom wire set. The customisation simplified the production line and reduced the amount of assembly time needed.

We have been supporting this customer for over 10 years, and have seen a steady increase in their annual order volumes. They also asked us for support with the design and specification of a new electronic ankle-worn security tag. This uses the same 10mm coin vibration motor that they use in their fall aid, due to the quality and price.

STAGE 1

Designing for application

- Our customer’s design required a low-energy drain on the battery, along with a long motor lifetime as the device was designed to be worn 24/7 including in the bath/shower.

- The device needed to be as slim and as light as possible. Market research had identified that users didn’t want to wear a bulky item.

STAGE 2

Manufacturing and testing

- Our team designed a custom wire set that helped reduce the amount of assembly time they needed on the customer’s production line.

- The device was fully tested, to ensure that it would be easy for a vulnerable person to use in the case of an emergency.

STAGE 3

Results and relationship

- Since the product launch, our customer has been purchasing from us for over 10 years and has gradually increased the volume of motors they are buying.

- Due to the quality of the coin vibration motor, they are now using the same motor solution in a new ankle tag product.

CASE STUDIES

We supply motor and mechanism solutions for all sorts of applications

-

Medical patient simulator

Patient simulator for first-aid cardiac arrest training required a vibration motor to haptic simulate a heartbeat.

View Case Study

-

Swarm robot research linear actuator

Challenging technical and unique application for swarm robotics for a European robotic research Institution.

View Case Study

-

Bench-top pill counting machine

Bench-top medical instrument used a vibration motor to aid movement of pills through instrument pathways.

View Case Study

-

Weather balloon measurement lab

High volumes of low-cost reliable single-use motors for weather balloon measurement lab.

View Case Study

-

Emergency services ruggedised radio

Emergency radios to withstand high temperatures, impacts, and vibrate through protective clothing

View Case Study

-

Surgically implanted pacemaker motor

Brushless vibration motor within a FDA Class III implanted medical pacemaker device.

View Case Study

MORE THAN YOUR AVERAGE MOTOR SUPPLIER

We manage your risk

We manage your risk through optimised design and rigorous testing, protecting your application and intellectual property, and fulfilling your performance requirements, whilst reducing your lifecycle costs.

MOTORS & MECHANISMS

Precision products

From off the shelf motor components to fully validated and tested complex mechanisms, choose a motor and mechanism partner you can trust.

-

DC motors

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf

View Page

-

DC gear motors

Building on our range of DC motors, we integrate spur and planetary gearboxes, from 6mm to 60mm frame diameters.

View Page

-

Vibration motors

With every vibration and haptic technology covered, we’ll help you select the best vibrating solution for your application.

View Page

-

Haptic feedback

Practical and reliable, low noise and high quality haptic feedback solutions for all types of application user interface.

View Page

-

Mechanisms

Custom motor assemblies designed and manufactured to your requirements. A turnkey service from design inputs to mass production.

View Page

-

Linear actuators

Precise, reliable and highly customisable linear actuators designed for a wide range of industrial, commercial and medical applications.

View Page

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies

Industries we serve

At Precision Microdrives we design and manufacture customised electric motors and mechanisms across a number of industries.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help.