Case study

PPE respirator hood system

- PPE respirator hood designed for industrial environments but re-purposed for medical / pharmaceutical industries.

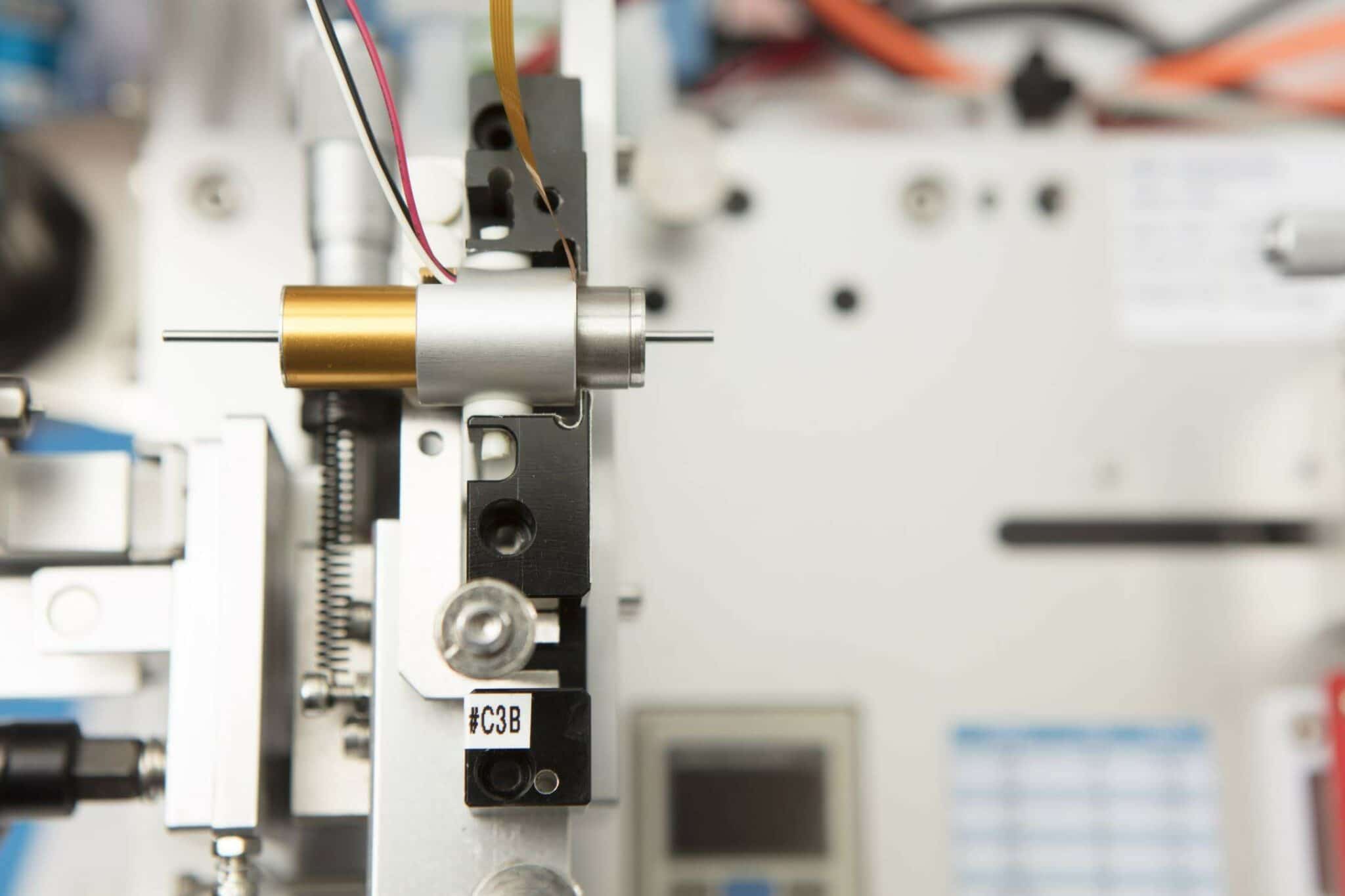

- A bespoke shrink wrapped vibration motor and mounting solution used in the notification system.

- 8mm ERM vibration motor

Challenge

- Our customer designed a respirator hood for the industrial sector and were looking to pivot to supply protection to frontline medical workers during the pandemic.

- The hood is battery operated so the motor needed to have a low energy drain.

- A control unit was designed in to generate three types of alert alarms: electronic audible, visual and vibration.

- They wanted to investigate the idea of including a vibration alerting/haptic feedback system into the medical hood.

Solution

- Our team of application engineers worked with our customer’s in-house team to design a bespoke shrink wrapped motor and mounting system.

- We reviewed the haptic feedback hood design and made some recommendations on how to improve the integration.

- Through sourcing an almost identical 2nd source motor we were able to ensure the customer was not impacted by the sudden international increase in demand for vibration motors.

- We set up a new manufacturing line specifically for this device so we could ensure we maintained the supply level they needed and could meet their delivery schedule.

Results

- We have been successfully manufacturing and supplying the bespoke solution for this customer for almost a decade.

- They had a consistent yearly order for the industrial hood motors but saw a huge increase in demand once it became available to frontline medical workers during the pandemic.

- Close cooperation between both parties led to a us being able to protect them from the risk of supply chain issues due to the huge demand in motors.

- We are the only supplier they are using to source and manufacture the solution for this device.

Project scope

PPE respiratory hood designed for industrial environments but re-purposed for medical and pharmaceutical workers.

Our multi-national bluechip customer designed a PPE respiratory hood to be used in industrial settings and tough environments, such as machine workshops, to protect the users from inhaling toxic gases, vapours and particles. Reducing the workers’ risk of developing life-changing illnesses.

The industrial hood was designed to cover the face and have a waist-mounted notification system. The notification system alerts the user to key pieces of information like the battery charge or airflow status.

When the pandemic started they contacted us as planned to re-design the industrial hood so it would be more comfortable for medical frontline and pharmaceutical workers. The medical hood was designed to cover the whole head and neck and would use the same waist-mounted notification system. They were also looking into adding some form of vibration / haptic feedback alerting system into the hood so the user would have more ways of being alerted to key information.

They knew the medical version of the hood was going to be a critical product so to ensure they could meet the demand, their monthly motor order increased overnight by 400%.

STAGE 1

Designing for application

- One of their key concerns was the importance of reducing the risk of the motor coming into contact with any dust or toxic particles, but having the power to issue a strong tactile alert.

- Following discussions with the customer we made changes to the motor mounting bracket to increase the strain relief of the motor.

- We worked with the customer to come up with an alert system that could be added into the hood.

STAGE 2

Testing and finalising

- The vibration motor was tested to ensure would be robust enough to survive being used in an industrial environment.

- The hood was tested by health and safety and achieve the EN 12941 Class TH2 and TH3 certification.

- We worked with them to fast-track an almost identical motor so they would have two sources for their motor needs.

- This reduced their risk of supply chain issues as the suppliers were in two different geographic locations.

STAGE 3

Results and relationship

- Due to our quick support during the pandemic we were fast-tracked as their preferred supplier for the new factory they have recently opened in Poland. This factory will service Europe and the Middle East markets.

- We have been recommended internally for several new projects across the business.

- By agreeing a long term order commitment we have proactively managed their supply chain risks including protecting them from the increase in raw material prices.

CASE STUDIES

We supply motor and mechanism solutions for all sorts of applications

-

Medical inhaled medication delivery device

Intelligent medical inhaler device, which was FDA Class III approved, required a gear motor mechanism to provide precise

View Case Study

-

Medical patient simulator

Patient simulator for first-aid cardiac arrest training required a vibration motor to haptic simulate a heartbeat.

View Case Study

-

Swarm robot research linear actuator

Challenging technical and unique application for swarm robotics for a European robotic research Institution.

View Case Study

-

Bench-top pill counting machine

Bench-top medical instrument used a vibration motor to aid movement of pills through instrument pathways.

View Case Study

-

Weather balloon measurement lab

High volumes of low-cost reliable single-use motors for weather balloon measurement lab.

View Case Study

-

Surgically implanted pacemaker motor

Brushless vibration motor within a FDA Class III implanted medical pacemaker device.

View Case Study

-

Digital medication management device

A digital medication management device for chronic disease patients taking controlled drugs, that sends reminders and feedback to

View Case Study

-

Chest percussive therapy device

Portable high-frequency chest percussive therapy (CPT) vest, designed to allow movement around the home during treatment.

View Case Study

-

Insulin monitoring device

High quality, reliable Precision Microdrives vibration motor design for FDA Class II diabetic insulin pump.

View Case Study

-

Lower limb prosthetic

Challenge Solution Results Project scope Vertically mounted coin vibration motors used in a lower leg prosthetic limb Our

View Case Study

More than your average motor supplier

We manage your risk

We manage your risk through optimised design and rigorous testing, protecting your application and intellectual property, fulfilling your performance requirements, whilst reducing your lifecycle costs.

MOTORS & MECHANISMS

Precision products

-

DC motors

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf

View Page

-

DC gear motors

Building on our range of DC motors, we integrate spur and planetary gearboxes, from 6mm to 60mm frame diameters.

View Page

-

Vibration motors

With every vibration and haptic technology covered, we’ll help you select the best vibrating solution for your application.

View Page

-

Haptic feedback

Practical and reliable, low noise and high quality haptic feedback solutions for all types of application user interface.

View Page

-

Mechanisms

Custom motor assemblies designed and manufactured to your requirements. A turnkey service from design inputs to mass production.

View Page

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies

Industries we serve

At Precision Microdrives we design and manufacture customised electric motors and mechanisms across a number of industries.

About PMD

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help.