Case study

Smart home blinds

- Smart home blinds system.

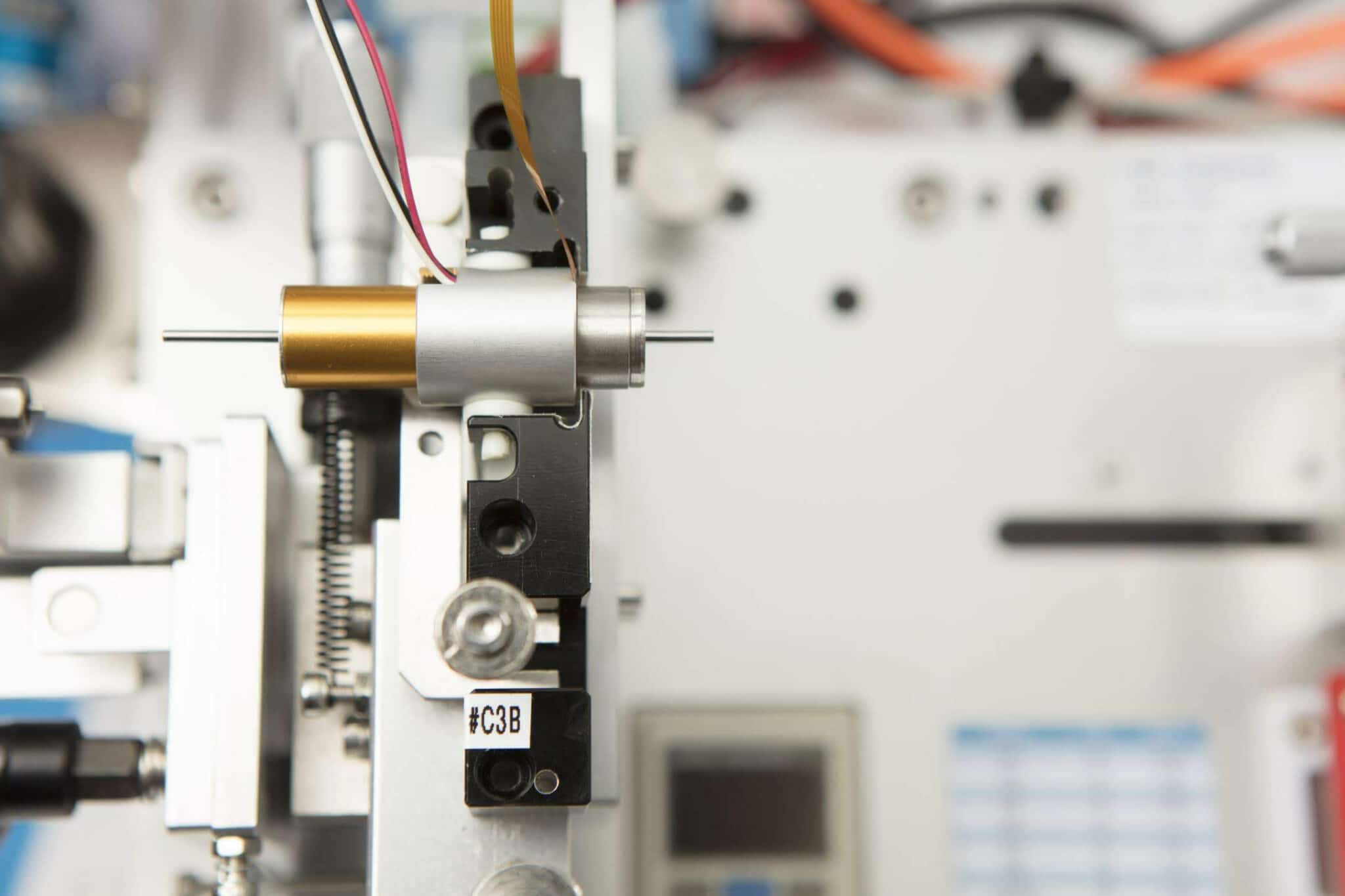

- Gearmotor mechanism for opening and closing integrated blinds.

- Brushless gearmotor solution with reduced footprint and cost.

Challenge

- The customer, a building company, had assembled a team of electronic engineers to add ‘smart home’ functionality to their pre-fab builds.

- Their engineering team contacted us seeking a motor control system for blinds which would be used to automatically control external heating during summer, alongside traditional functions such as privacy.

- The customer had designed and prototyped a system that would enable the motor to be placed either side of the blind roller, but had performed no design-for-manufacture studies.

Solution

- We studied the design that the customer had prepared, and immediately noticed the challenges surrounding how readily it could be manufactured.

- The customer had designed their transfer gearbox with a specific motor in mind. We were able to counter-propose a smaller brushless gear motor with sufficient performance that would fit within the dimensions of a regular blind roller.

- This greatly simplified the mounting and integration of the blinds, the manufacturing costs, and enabled the customer to market the blinds outside of their regular pre-fab houses business.

Results

- We recognised that the customer’s engineering team had great ideas, but little experience in mass production, so proposed a different route for them to head down.

- Our final solution was more useful in a wider range of situations owing to its 60% more effective use of space with the blind cavity.

- Our mechanism was estimated to be 35% less cost to produce their design, which itself was far from being production ready.

- After only one engagement with PMD, our customer choose to make us a long-term partner.

Project scope

Solar powered motorised blind mechanism for pre-fabricated smart homes

Our customer is a building company that manufactured pre-fabricated homes. They wanted pre-integrate electronic ‘smart home’ products into their builds to meet evolving customer expectations.

Their team of electronic engineers were smart and had great ideas, but lacked the experience of mass production. We reviewed their prototype designs and discovered that a considerable amount of design for manufacture was necessary to bring them to market.

The customer had gone down this route, because they hadn’t clearly understood what motor form factors were available. We were able to identify a package that would operate the blinds from within the internal void of the blind roller – space that had previously been wasted.

This enabled the customer to not only fit them more efficiently in their builds, but enabled them also to sell them as stand-alone solutions outside their existing market.

STAGE 1

Designing for application

- We started the project with a design review of the customer’s existing design.

- The design looked great on paper, but had been created with an imperfect view of the gear motors that they could use.

- Their design was also impractical to manufacture efficiently without a lot of additional design work, and they had missed a different approach that saw the gear motor integrated inside the blind roller, instead of outside it.

STAGE 2

Testing and finalising

- Our proposed design was smaller, simpler, consumed less power but was not built like a tank. It was rather built under our value engineering principles, and was therefore more than ‘good enough’, but not overly engineered.

- We manufactured prototypes and proceeded to test them on our longevity dynamometers with the same loading they would experience in application.

- They passed, and the customer placed orders for their expected 18 month demand.

STAGE 3

Results and relationship

- The cost of manufacture was estimated to be 35% less with our design than with the original design, although this did not include any of the DFM work that would have been required (and amortised) on the customer’s design.

- 60% more effective use of space.

- After only one engagement with PMD our customer choose to make us a long-term partner responsible for the design of the complete product including manufacture, assembly and packaging.

CASE STUDIES

We supply motor and mechanism solutions for all sorts of applications

-

Medical patient simulator

Patient simulator for first-aid cardiac arrest training required a vibration motor to haptic simulate a heartbeat.

View Case Study

-

Swarm robot research linear actuator

Challenging technical and unique application for swarm robotics for a European robotic research Institution.

View Case Study

-

Bench-top pill counting machine

Bench-top medical instrument used a vibration motor to aid movement of pills through instrument pathways.

View Case Study

-

Weather balloon measurement lab

High volumes of low-cost reliable single-use motors for weather balloon measurement lab.

View Case Study

-

Emergency services ruggedised radio

Emergency radios to withstand high temperatures, impacts, and vibrate through protective clothing

View Case Study

-

Surgically implanted pacemaker motor

Brushless vibration motor within a FDA Class III implanted medical pacemaker device.

View Case Study

MORE THAN YOUR AVERAGE MOTOR SUPPLIER

We manage your risk

We manage your risk through optimised design and rigorous testing, protecting your application and intellectual property, fulfilling your performance requirements whilst reducing your lifecycle costs.

MOTORS & MECHANISMS

Precision products

From off the shelf motor components to fully validated and tested complex mechanisms, choose a motor and mechanism partner you can trust.

-

Mechanisms

Custom motor assemblies designed and manufactured to your requirements. A turnkey service from design inputs to mass production.

View Page

-

Vibration motors

With every vibration and haptic technology covered, we’ll help you select the best vibrating solution for your application.

View Page

-

DC motors

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf

View Page

-

DC gear motors

Building on our range of DC motors, we integrate spur and planetary gearboxes, from 6mm to 60mm frame diameters.

View Page

-

Haptic feedback

Practical and reliable, low noise and high quality haptic feedback solutions for all types of application user interface.

View Page

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies

Industries we serve

At Precision Microdrives we design and manufacture customised electric motors and mechanisms across a number of industries.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help.