Case study

Chest percussive therapy device

- Portable home use Chest Percussive Therapy (CPT) device, for treating chronic respiratory conditions.

- Brushless motor needed due to the product life-time requirements.

- 16 robust vibration motors per device, mounted in individual enclosures.

Challenge

- Our customer was seeking help with re-designing the mounts and electronics for their chest percussive therapy vest, along with sourcing a stronger motor to maximise the vibration transmitted to a patient’s torso during treatment.

- The vest needed to be able to provide pulse therapy as well as continual vibrations, as a patient can need both types of treatment.

- This device was going to be battery powered, and could be used at full power for up to 30 minutes at a time, three times a day. This meant they were looking for low energy drain on the battery.

Solution

- We reviewed their specification and were able to offer a selection of vibration motors that matched their amplitude and frequency requirements. They tested samples of these different motors.

- We discussed with them the option of using a brushless vibration motor, as it offers a high amplitude and extended longevity, so this could be better for the pulse setting they wanted.

- Though further discussions, we discovered we could offer a considerable cost down, by supplying the motors and the drivers.

Results

- The samples passed all the customers internal tests, including strength and longevity.

- The vest protype is going through clinical trials, ahead of recieving its FDA approval.

- The relationship is ongoing, as we are continuing to support them with getting their product to market.

Project scope

Portable high-frequency chest percussive therapy (CPT) vest, designed to allow movement around the home during treatment.

Our customer designed a battery operated chest percussive therapy (CPT) or high-frequency chest wall oscillation (HFCWO) device to support patients with a range of respiratory conditions, to clear their airways at home. It is designed to replicate the physiotherapy the user would receive from a medical professional but enables the patient to administer the treatment themselves and in the comfort of their own homes.

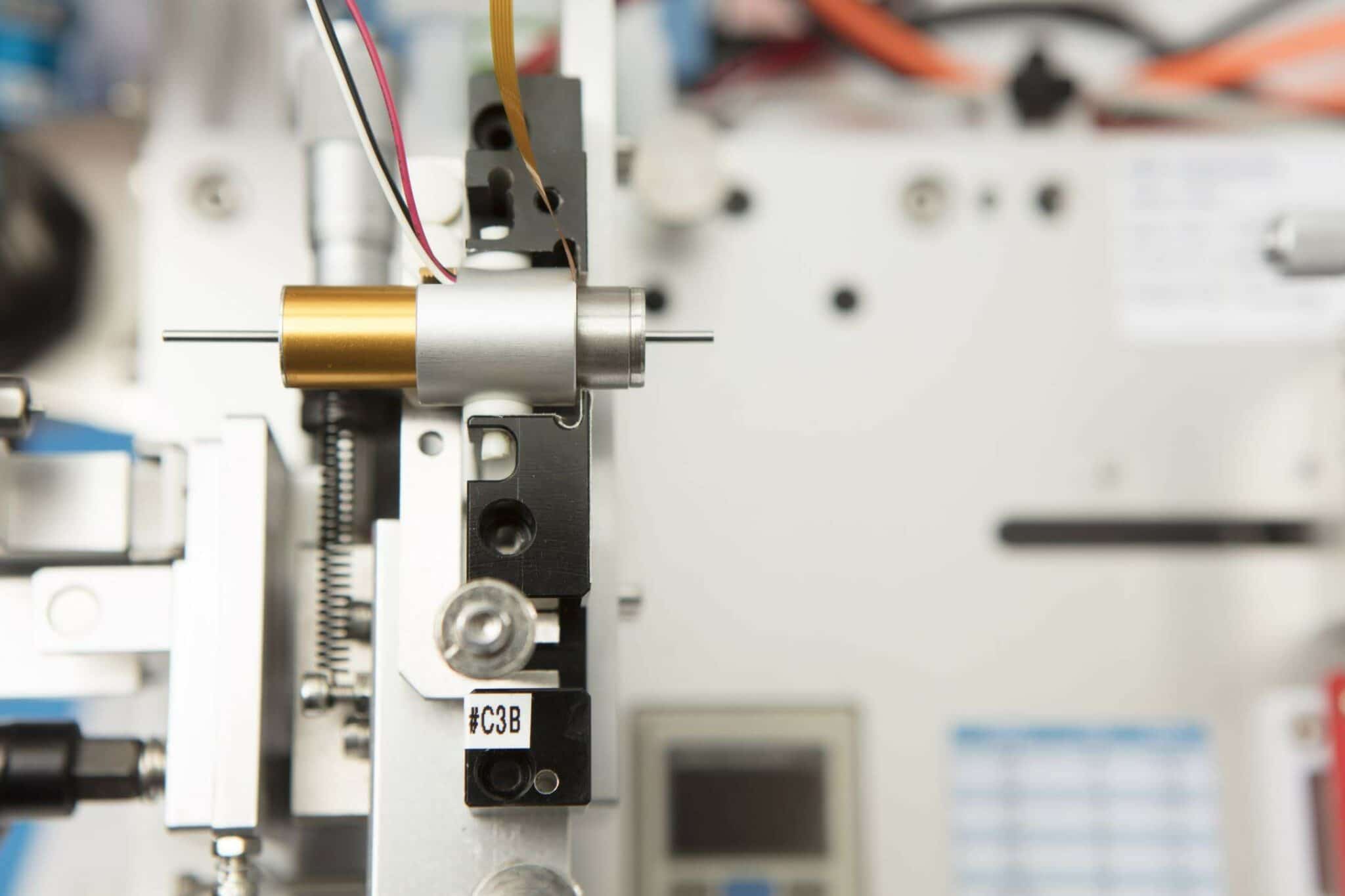

The vest has 16 motors, each mounted in its own enclosure and divided into eight treatment zones that can all be operated individually to provide therapy in specific areas. The motors can be sent to either provide continuous vibration or to pulse, depending on the treatment required/needed.

The customer had bought some of our motors to test through a design agency, but was unaware of the level of service or customisation we could provide. They reached out to us as they wanted to see if we could recommend a more suitable motor for their device.

STAGE 1

Designing for application

- Our customer needed a very strong and durable vibration motor, with at least 60G amplitude.

- The motor needed to be powerful enough, to clear any mucus congestion from a patients airways.

- They had limited amount of space so the motors needed to be small, although they were open to re-designing the motor housing if necessary.

STAGE 2

Manufacturing and testing

- Our customer had a clear idea on the strength of motor they needed to have but they lacked the technical knowledge to know what type of motor they should be using.

- Our experienced team worked with their designers, to trial several motors to discover which one would be the most suitable.

STAGE 3

Results and relationship

- Our customer was expecting the long-life brushless motor solution we decided on to be expensive, but we were able to design a suitable motor that was lower in cost, but with the high amplitude motor we needed.

- The vest is still going through its clinical trials ahead of gaining its FDA class II approval, and we are continuing to support and work with our customer as their primary supplier.

CASE STUDIES

We supply motor and mechanism solutions for all sorts of applications

-

Medical patient simulator

Patient simulator for first-aid cardiac arrest training required a vibration motor to haptic simulate a heartbeat.

View Case Study

-

Swarm robot research linear actuator

Challenging technical and unique application for swarm robotics for a European robotic research Institution.

View Case Study

-

Bench-top pill counting machine

Bench-top medical instrument used a vibration motor to aid movement of pills through instrument pathways.

View Case Study

-

Weather balloon measurement lab

High volumes of low-cost reliable single-use motors for weather balloon measurement lab.

View Case Study

-

Emergency services ruggedised radio

Emergency radios to withstand high temperatures, impacts, and vibrate through protective clothing

View Case Study

-

Surgically implanted pacemaker motor

Brushless vibration motor within a FDA Class III implanted medical pacemaker device.

View Case Study

MORE THAN YOUR AVERAGE MOTOR SUPPLIER

We manage your risk

We manage your risk through optimised design and rigorous testing, protecting your application and intellectual property, and fulfilling your performance requirements, whilst reducing your lifecycle costs.

MOTORS & MECHANISMS

Precision products

From off the shelf motor components to fully validated and tested complex mechanisms, choose a motor and mechanism partner you can trust.

-

DC motors

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf

View Page

-

DC gear motors

Building on our range of DC motors, we integrate spur and planetary gearboxes, from 6mm to 60mm frame diameters.

View Page

-

Vibration motors

With every vibration and haptic technology covered, we’ll help you select the best vibrating solution for your application.

View Page

-

Haptic feedback

Practical and reliable, low noise and high quality haptic feedback solutions for all types of application user interface.

View Page

-

Mechanisms

Custom motor assemblies designed and manufactured to your requirements. A turnkey service from design inputs to mass production.

View Page

-

Linear actuators

Precise, reliable and highly customisable linear actuators designed for a wide range of industrial, commercial and medical applications.

View Page

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies

Industries we serve

At Precision Microdrives we design and manufacture customised electric motors and mechanisms across a number of industries.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help.