Linear Resonant Actuators

Within our Precision Haptic™ range of vibration motors, we offer several types of Linear Resonant Actuator (LRA) vibration motors (also known as linear vibrators). LRA motors are different to Eccentric Rotating Mass (ERM) vibration motors in the way that they work, they are used, and how long they last.

If you have an application that requires a durable vibration, or a high confidence MTTF rating, consider our Linear Resonant Actuator vibration motors as an alternative to long-life brushless vibration motors. But, understand that that longer life and control does come at a slightly increased cost of complexity – continue reading to find out more.

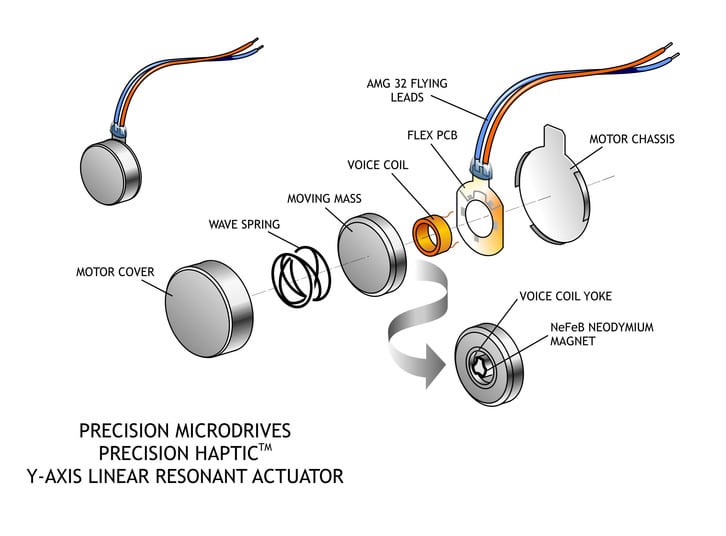

General Construction For A Y-Axis LRA Linear Vibrator

The illustration above shows the general arrangement of parts within a Y-axis LRA vibration motor. Those readers familiar with audio engineering will note that the voice coil drive is very similar to that loudspeaker. However, instead of a cone that generates sound pressure waves, there is a mass that generates vibrations.

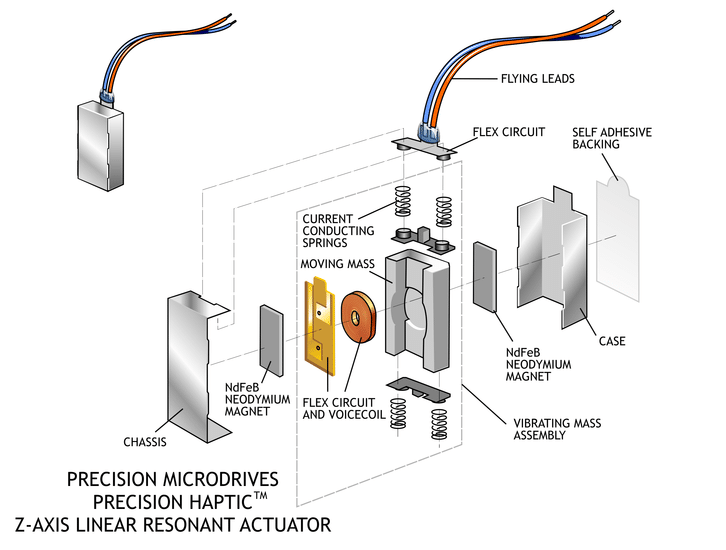

Below is another LRA which works in the same way, however, the vibrations are directed in only the Z-axis. This offers users a greater choice in design as they can produce vibrations in either horizontal or vertical directions.

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

A magnetic field is generated by the voice coil which interacts with the magnet mass, which is suspended on a spring. As the magnetic field varies with the applied drive signal, the magnet and mass are moved up and down as they interact with the spring.

Resonant Frequency Of Operation

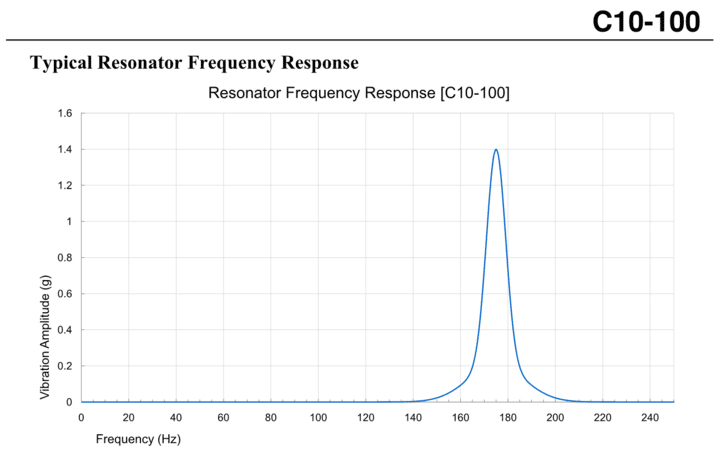

Again, those readers familiar with vibration, RF, or audio engineering, will quickly spot that attaching a mass to a spring causes a resonance effect. The combination of spring stiffness, mass and magnet/coil size will cause the linear vibrator to have a natural resonant frequency.

This natural resonant frequency is where the LRA is most efficient in its operation, as can be seen by the output amplitude vs frequency on the bode plot above for our C10-100 Linear Resonant Actuator.

Typically for Y-axis vibrators, resonant frequencies are around 175 – 235 Hz, see our range here.

Driving Linear Resonant Actuators / Linear Vibrators

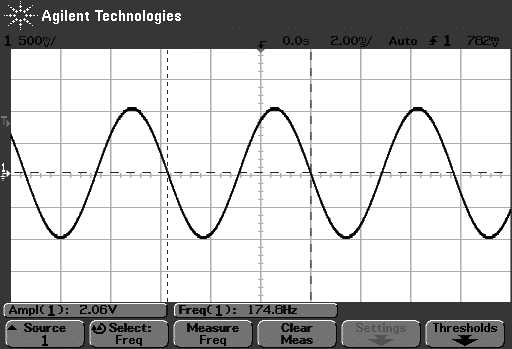

LRA linear vibrators need to be driven with an AC signal, much like a loudspeaker. It is preferable that this signal is a sinewave at the resonant frequency as shown below.

The driving waveform can, of course, be amplitude modulated to generate more advanced haptic feedback effects.

Take a read of our application bulletin about driving LRA vibration motors to learn more.

Extended Lifetime For Linear Vibrators

Unlike most vibration motors which have an electromechanical commutation, LRA vibration motors are effectively brushless as they use a voice-coil to drive the mass. This means that the only moving parts that are prone to failure are the springs. These springs are modelled with finite element analysis (FEA) and are operated within their non-fatigue zone.

With little mechanical wear, failure modes are restricted to ageing of internal components which results in much longer MTTF failure modes than traditional brushed eccentric rotating mass (ERM) vibration motors.

We also sell an increasing range of brushless ERM motors which offer long-life vibration in two planes rather the single plane offered by the LRA motors.

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.