Case study

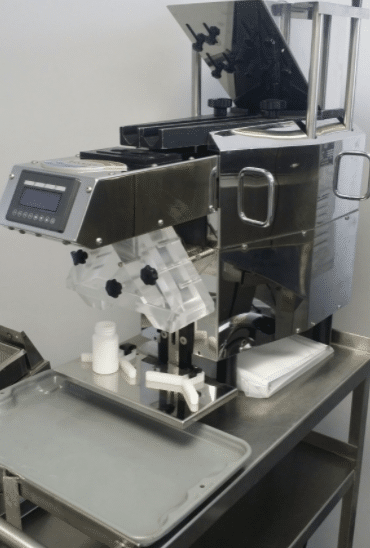

Bench-top pill counting machine

- Bench-top medical instrument.

- Vibration motor to aid movement of pills through instrument pathways.

- Kit of two long-life vibration motors with fittings and a resonance controller.

Challenge

- Our customer’s machines were being upgraded to handle larger quantities of pill and tablets.

- In some climates the humidity would cause the tablets to temporarily block the internal pathways of the machine.

Solution

- A kit of long lasting vibration motors that could be affixed to the machine hoppers in several locations.

- We designed a long-life brushed motor with custom eccentric mass, to hit a target vibration frequency and amplitude, to induce resonance.

Results

- We used a spot-welding manufacturing technique for the chassis, and added a PCB backpack onto the motor to include an X2Y EMI filter.

- Provided an innovative solution and created an end-of-line testing station to ensure frequency and amplitude targets were met.

Project scope

Instrument upgrade

Vibration is not only used for haptic feedback, and user interface notifications. In this example our customer is a manufacturer of bench-top pill and tablet counters.

Some parts of their machines were being upgraded to handle larger quantities of pill and tablets, and in some climates the humidity would cause the tablets to temporarily block the internal pathways of the machine.

The customer tasked us with designing and manufacturing a kit of long lasting vibration motors, that could be affixed to the machine hoppers in several locations.

This mechanically aided the pills in their journey through the machine, preventing blockages. The kit contained two durable vibration motors, fixing enclosures, mounting fasteners, flying leads, & an electronic motor driver.

STAGE 1

Designing for application

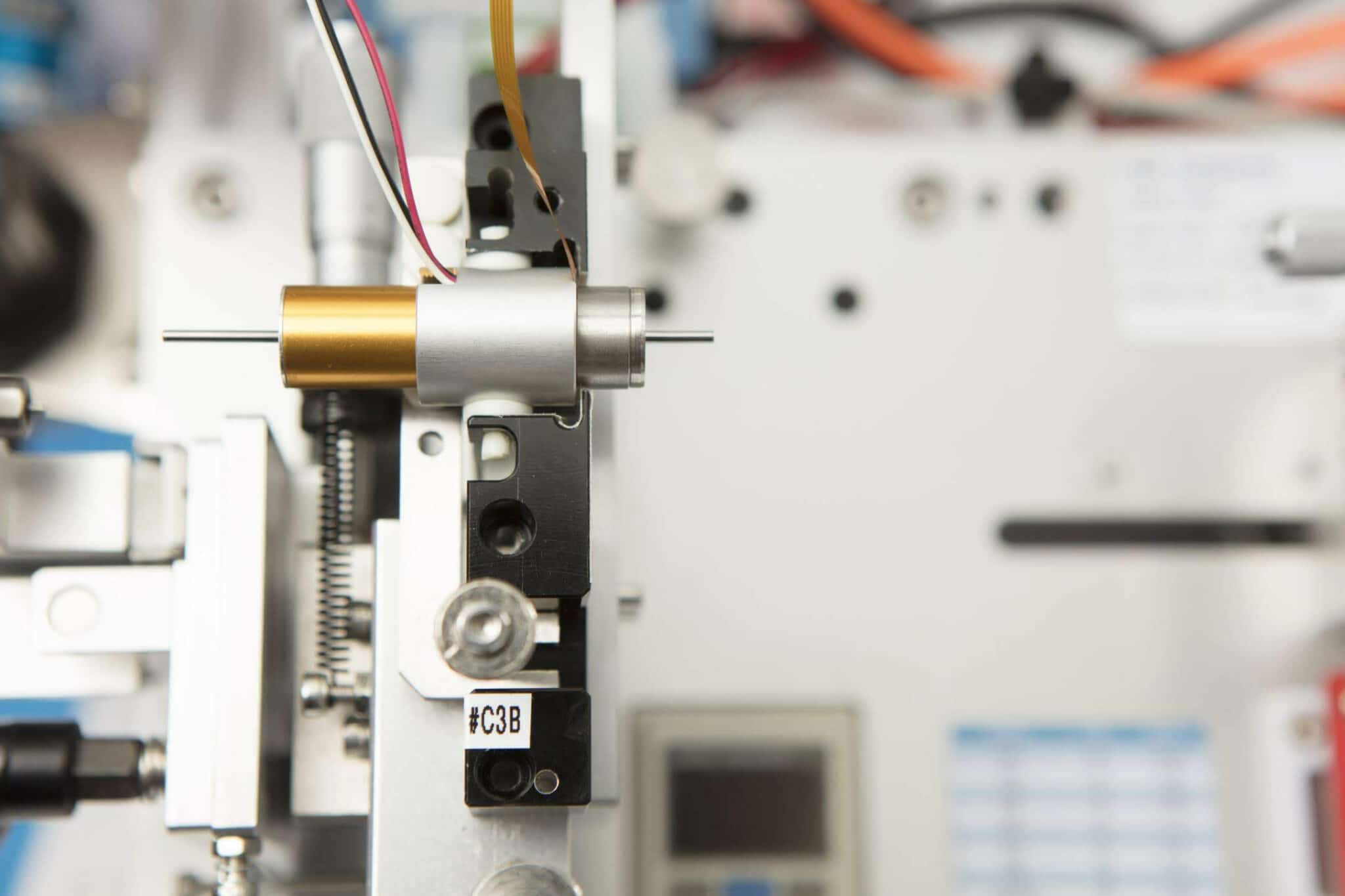

- The first technical job on this project was to understand the frequency and magnitude of vibration required to hit mechanical resonance, and dislodge blockages within the machine.

- We had been given lifetime and environmental requirements, and after initial prototype testing our team designed a long-life brushed motor with eccentric mass that would hit the target vibration frequency and amplitude.

STAGE 2

Manufacturing and testing

- The customer confirmed the preferred fixing points on their machine, and we designed a chassis enclosure that would secure the motor whilst protecting it from humidity and dust.

- We used a spot-welding manufacturing technique for the chassis, and added a PCB backpack onto the motor to include a EMI filter.

- The flying leads were secured with epoxy to the PCB backpack, for strain relief. The whole wiring harness was secured further with a spot-welded strain relief fixture onto the chassis.

STAGE 3

Precision delivery

- The two motors, fixing components, wire sets and driver module, were all serialised, labelled and kitted together into a single carton package with protective foam and fitting instructions.

- PMD’s testing infrastructure allowed us to assure our client that the product was verified and reliable, managing their risk throughout.

- Every production batch was delivered on time and to spec.

- Positive relationship, leading to follow-up collaborations.

CASE STUDIES

We supply motor and mechanism solutions for all sorts of applications

-

Medical inhaled medication delivery device

Intelligent medical inhaler device, which was FDA Class III approved, required a gear motor mechanism to provide precise dosage for

View Case Study

-

Medical patient simulator

Patient simulator for first-aid cardiac arrest training required a vibration motor to haptic simulate a heartbeat.

View Case Study

-

Swarm robot research linear actuator

Challenging technical and unique application for swarm robotics for a European robotic research Institution.

View Case Study

-

Bench-top pill counting machine

Bench-top medical instrument used a vibration motor to aid movement of pills through instrument pathways.

View Case Study

-

Weather balloon measurement lab

High volumes of low-cost reliable single-use motors for weather balloon measurement lab.

View Case Study

-

Surgically implanted pacemaker motor

Brushless vibration motor within a FDA Class III implanted medical pacemaker device.

View Case Study

MORE THAN YOUR AVERAGE MOTOR SUPPLIER

We manage your risk

We manage your risk through optimised design and rigorous testing, protecting your application and intellectual property, and fulfilling your performance requirements, whilst reducing your lifecycle costs.

MOTORS & MECHANISMS

Precision products

From off the shelf motor components to fully validated and tested complex mechanisms, choose a motor and mechanism partner you can trust.

-

DC motors

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf

View Page

-

DC gear motors

Building on our range of DC motors, we integrate spur and planetary gearboxes, from 6mm to 60mm frame diameters.

View Page

-

Vibration motors

With every vibration and haptic technology covered, we’ll help you select the best vibrating solution for your application.

View Page

-

Haptic feedback

Practical and reliable, low noise and high quality haptic feedback solutions for all types of application user interface.

View Page

-

Mechanisms

Custom motor assemblies designed and manufactured to your requirements. A turnkey service from design inputs to mass production.

View Page

Discover More

Resources and guides

Discover our product application notes, design guides, news and case studies

Industries we serve

At Precision Microdrives we design and manufacture customised electric motors and mechanisms across a number of industries.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help.