Coreless motors

A wide range of high-quality, and cost-effective, sub-Ø20 mm coreless DC motors, with optional gearboxes and encoders.

We offer a comprehensive range of DC coreless motors with precious metal brushes, matching gearboxes, and encoders. Our motors feature high density windings, neodymium alloy magnets, CNC or stamped enclosures, and preloaded ball bearings. We design matching driver and controller solutions to your application requirements, and offer simulated application validation and lifetime testing services.

| Product Image | Part Number | Stock Level | Motor Type | Diameter (mm) | Length (mm) | Voltage (V) | No-load Current (A) | No-load Speed (rpm) | Stall Torque (mNm) | Stall Current (A) | Nominal Torque (mNm) | Nominal Speed (rpm) | Nominal Current (A) | Commutation |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

104-10J

Download Datasheet |

10 | Coreless | 4 | 8.1 | 3 | 0.011 | 51500 | 0.059 | 0.144 | 0.03 | 3580 | 0.080 | Precision metal brushes |

|

104-008

Download Datasheet |

Made to order | Coreless | 4 | 8.1 | 2.4 | 0.017 | 54480 | 0.066 | 0.213 | 0.03 | 3580 | 0.106 | Precision metal brushes |

|

104-10L

Download Datasheet |

Made to order | Coreless | 4 | 8.1 | 3.7 | 0.009 | 54000 | 0.055 | 0.066 | 0.030 | 3580 | 0.066 | Precision metal brushes |

|

106-10F

Download Datasheet |

Made to order | Coreless | 6 | 9.3 | 5 | 0.010 | 30800 | 0.13 | 0.10 | 0.08 | 3580 | 0.065 | Precision metal brushes |

|

106-10E

Download Datasheet |

8 | Coreless | 6 | 9.3 | 3 | 0.017 | 32435 | 0.141 | 0.185 | 0.08 | 3580 | 0.017 | Precision metal brushes |

|

106-10C

Download Datasheet |

35 | Coreless | 6 | 10.8 | 3 | 0.016 | 34330 | 0.32 | 0.625 | 0.12 | 3580 | 0.170 | Precision metal brushes |

|

108-400

Download Datasheet |

42 | Coreless | 8 | 16.8 | 6 | 0.018 | 15560 | 1.39 | 1.39 | 0.60 | 3580 | 0.190 | Precision metal brushes |

|

108-10F

Download Datasheet |

Made to order | Coreless | 8 | 16.8 | 6 | 0.018 | 15560 | 1.39 | 1.39 | 0.60 | 3580 | 0.190 | Precision metal brushes |

|

108-201

Download Datasheet |

Made to order | Coreless | 8 | 16.8 | 6 | 0.018 | 15560 | 1.39 | 1.39 | 0.60 | 3580 | 0.190 | Precision metal brushes |

|

110-203

Download Datasheet |

Made to order | Coreless | 10 | 15 | 10.0 | 0.015 | 18740 | 2.97 | 0.66 | 0.75 | 3580 | 0.180 | Precision metal brushes |

|

110-108

Download Datasheet |

23 | Coreless | 10 | 15 | 8.0 | 0.027 | 13695 | 2.88 | 0.785 | 0.70 | 3580 | 0.215 | Precision metal brushes |

|

110-202

Download Datasheet |

18 | Coreless | 10 | 15 | 10.0 | 0.015 | 18740 | 2.97 | 0.66 | 0.75 | 3580 | 0.180 | Precision metal brushes |

|

110-600

Download Datasheet |

75 | Coreless | 10 | 20.7 | 18 | 0.012 | 18460 | 6.77 | 0.95 | 1.00 | 3580 | 0.150 | Precision metal brushes |

|

110-109

Download Datasheet |

Made to order | Coreless | 10 | 20.7 | 3 | 0.080 | 21100 | 7.33 | 6.00 | 1.00 | 3580 | 0.890 | Precision metal brushes |

|

110-400

Download Datasheet |

Made to order | Coreless | 10 | 20.7 | 12 | 0.020 | 21800 | 8.47 | 1.79 | 1.00 | 3580 | 0.230 | Precision metal brushes |

|

112-600

Download Datasheet |

22 | Coreless | 12 | 15.2 | 15 | 0.009 | 17755 | 3.46 | 0.515 | 0.90 | 3580 | 0.140 | Precision metal brushes |

|

112-109

Download Datasheet |

175 | Coreless | 12 | 15.2 | 5.0 | 0.043 | 22615 | 4.18 | 2.085 | 1.00 | 3580 | 0.535 | Precision metal brushes |

|

112-408

Download Datasheet |

Made to order | Coreless | 12 | 15.2 | 9.0 | 0.018 | 18375 | 3.71 | 0.900 | 0.95 | 3580 | 0.245 | Precision metal brushes |

|

112-601

Download Datasheet |

16 | Coreless | 12 | 20.8 | 6.0 | 0.014 | 8215 | 6.66 | 1.04 | 2.25 | 3580 | 0.360 | Precision metal brushes |

|

112-20A

Download Datasheet |

Made to order | Coreless | 12 | 20.8 | 3.0 | 0.028 | 9150 | 6.67 | 2.31 | 2.10 | 3580 | 0.745 | Precision metal brushes |

Filter products

Sample request

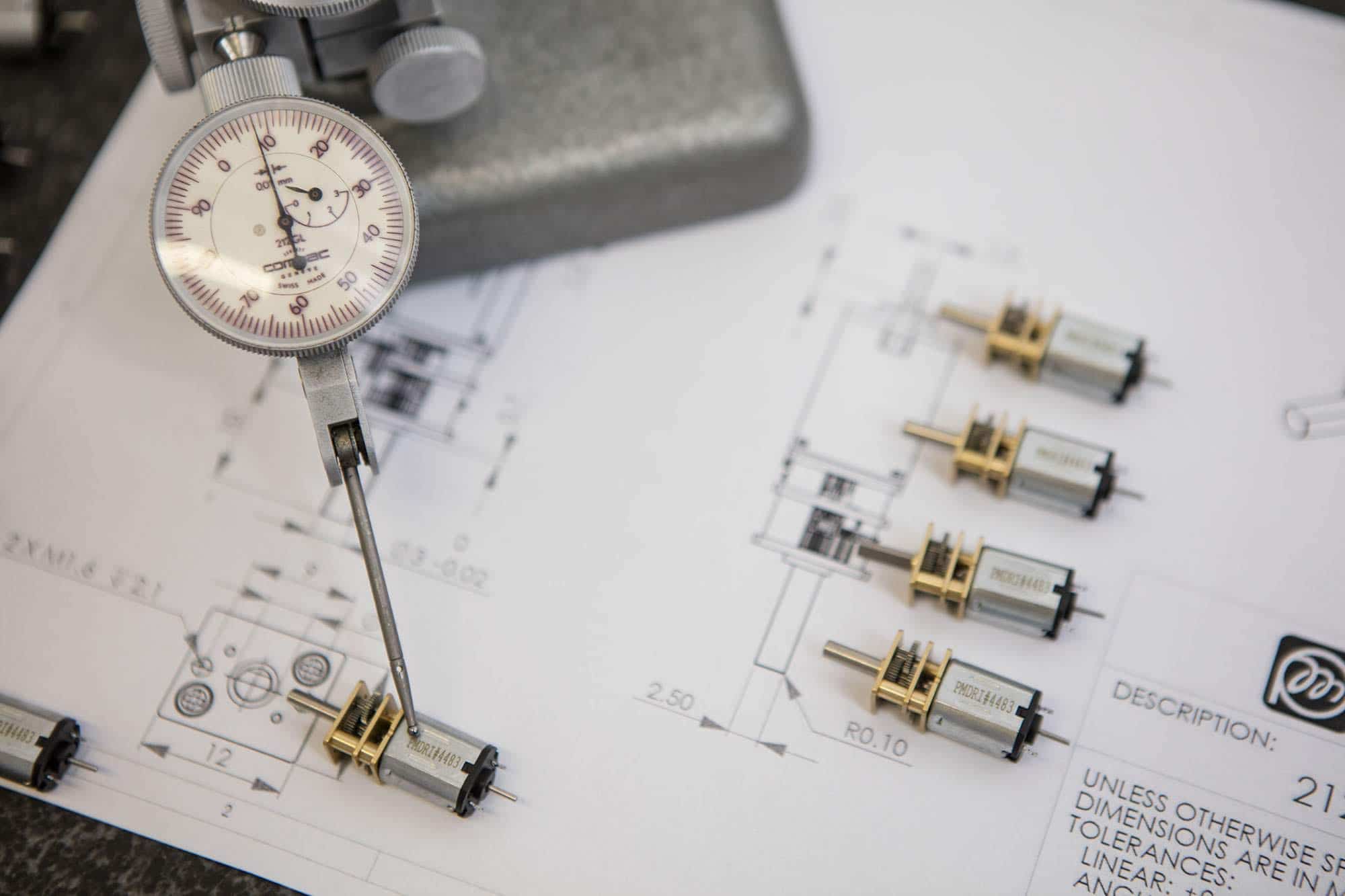

We aim to get you up and prototyping as quickly as possible. We stock off-the-shelf samples for each motor size, to support commercial development.

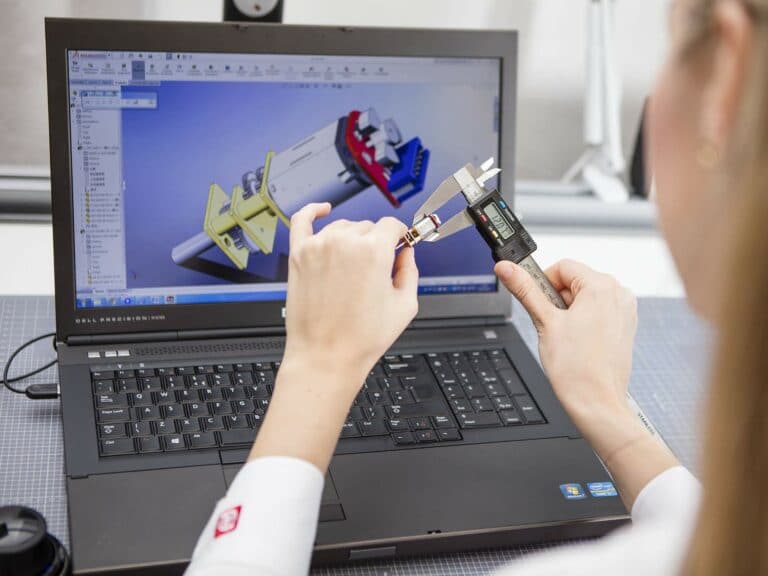

Our application engineers can advise on motor design and selection, mechanism design, and support the development of high performance motor drivers. They can also assist to validate the in-application performance and longevity suitability of a down-selected motor or mechanism design.

Contact our application engineering team to discuss your project, using the form, or email [email protected].

We design and manufacture DC Coreless motors:

- Frame diameters from Ø4mm to Ø20mm,

- Coreless high density windings,

- Winding voltages from 2.4v to 18v, with a variety of windings available off-the-shelf for sampling,

- A range matching planetary gearboxes with ratios from 1:4 to 1:3372,

- A range of matching encoders providing ABN, and UWV outputs,

- Precious metal brushes.

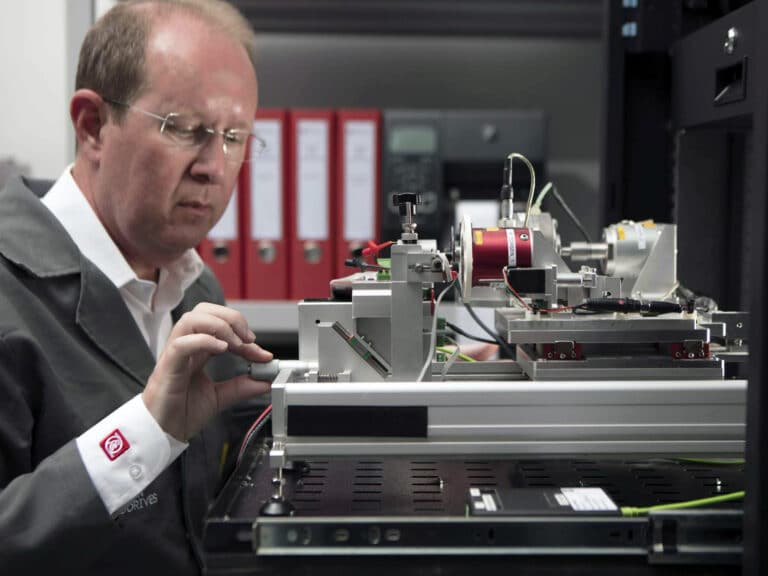

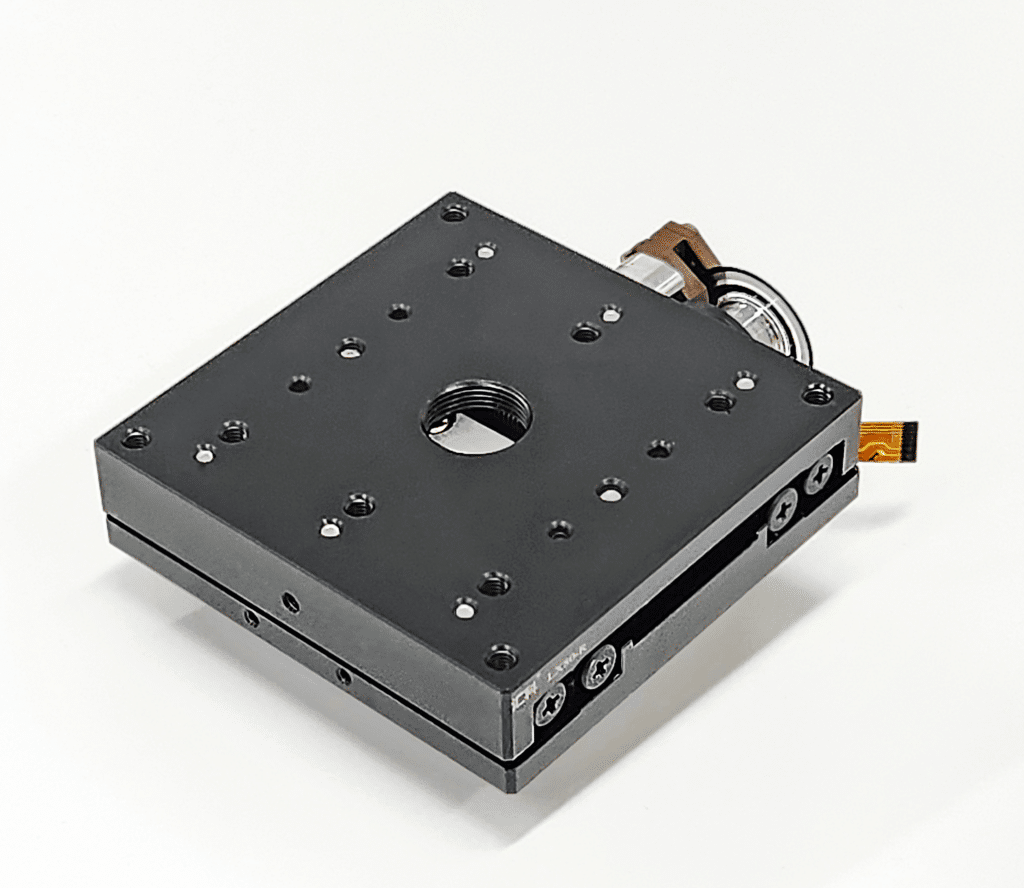

We also design and manufacture quick turnaround mechanisms using coreless motors:

- Slider tables,

- Ball screw and belt drive positioners,

- Levers, cams and other slider arrangements,

- Complex mechanisms: Fully bespoke ground-up designs for complex applications,

Contact our application engineering team to discuss your project [email protected], or use the contact form below.

MORE THAN YOUR AVERAGE MOTOR SUPPLIER

Precision mechanisms

We use our proven technology to solve your motor problems, reducing costs and managing your risk through optimised design.

Specialised engineering services and capabilities

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.

Case studies

View our past projects with examples of various different applications utilising custom-made motor and mechanism solutions from Precision Microdrives.