Haptic feedback

Practical solutions for adding haptics to your application

We deliver a high performance haptic feedback user experience

Haptic feedback is where your product communicates with the user, via their sense of touch.

There are many haptic feedback technologies, and almost as many ‘technology startups’ promoting them. Some of these do offer effective and unique touch feedback experiences, but many are either too expensive or work only in a handful of niche use-cases.

Our focus is on haptic feedback that works reliably and cost effectively in real-world applications.

To do that, we use a mature and proven combination of:

- Applied experience

- Vibration actuators

- Touch surface suspension

- Advanced programmable haptic controllers

Understand haptics

Learn more about using haptics in your application.

WHAT DO YOU NEED

Haptic feedback or vibration alerting?

Adding haptics to a device can be quite challenging, even with expert help. Before you embark on that journey, consider whether haptic feedback is really what you need. Perhaps it’s simpler implementation, vibration alerting is more than good enough?

Haptic feedback is a tactile user interface

Haptic feedback uses very controlled vibration or actuated movement, to provide touch feedback or information to a user. It is a tactile user interface and enables a device to speak the ‘language’ of haptics, adding complexity.

The most obvious implementation of this is a touch screen, where haptic feedback takes the form of simulating the feeling of pressing a button.

A more complex example would be a glove with many haptic actuators on it to support training of a surgeon in a virtual reality environment.

Vibration alerting is a tactile alarm

Vibration alerting is a lot simpler. It’s a binary on / off signal to a user to grab their attention.

Think of an incoming phone call, vibration on a steering wheel to alert the driver that they have veered across a lane marking, or a vibrating crane control stick to signal that the attached load is too heavy.

Vibration alerting can also be quite elaborate – think of a belt with 12 integrated vibration motors to direct the wearer where to go. Most people call this haptics, but it’s actually just vibration alerting.

Why the big deal with semantics? Well in a nutshell, if you’re vibration alerting the project is going to be much simpler and cheaper.

The components of haptic feedback

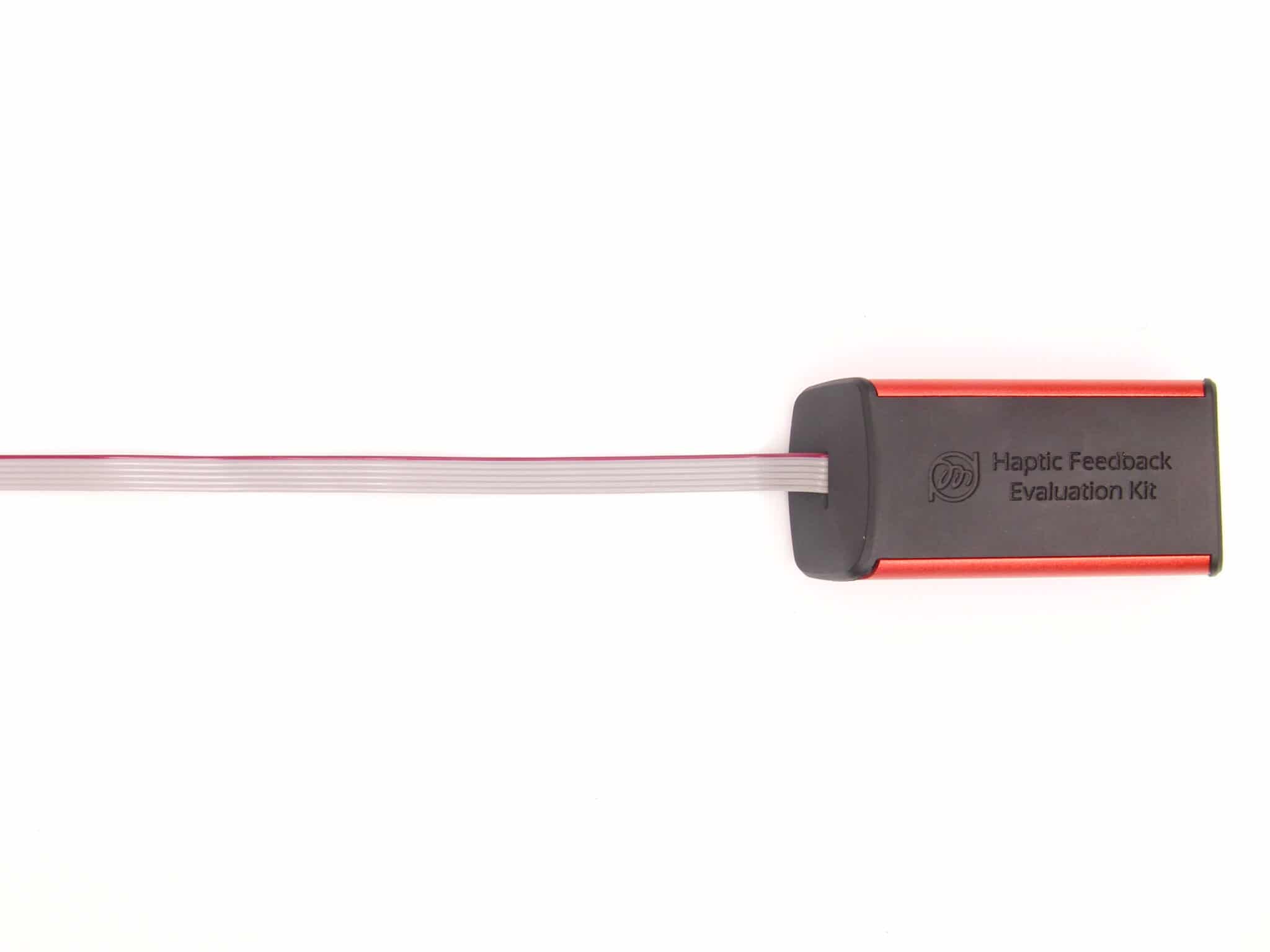

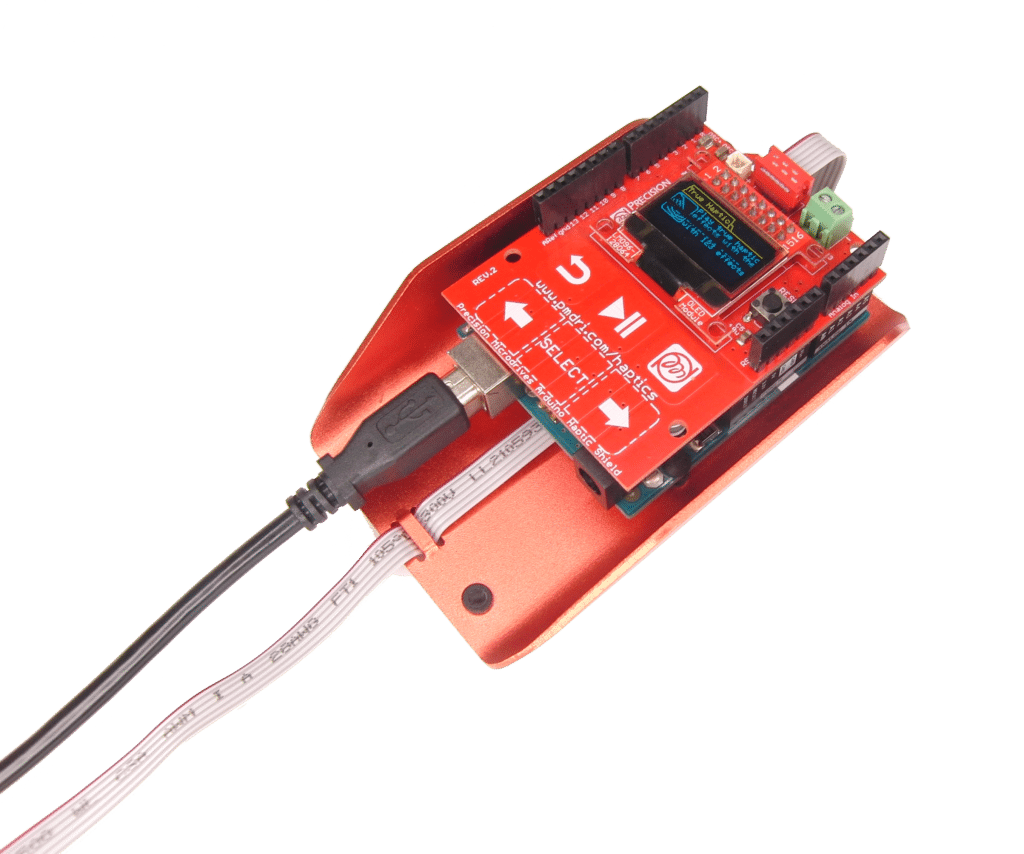

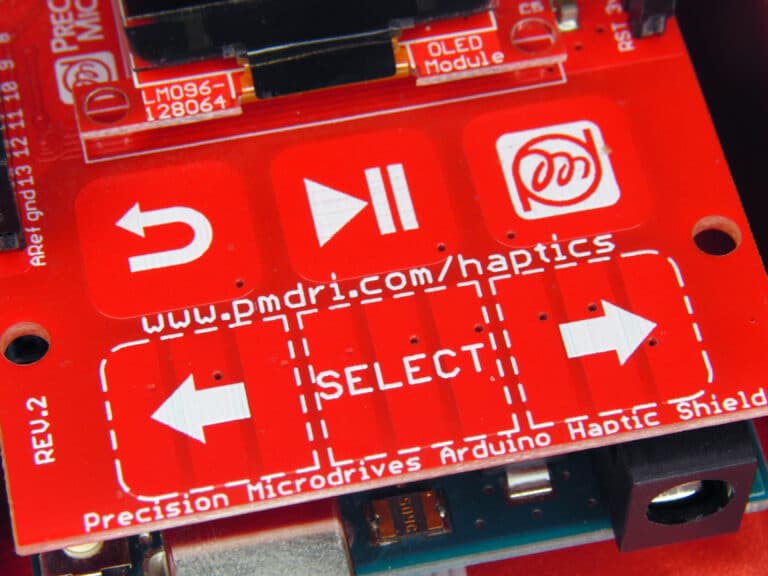

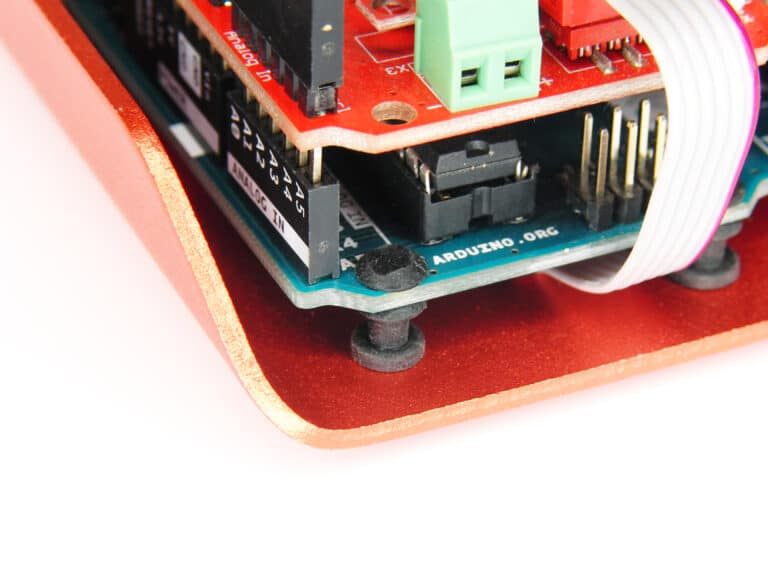

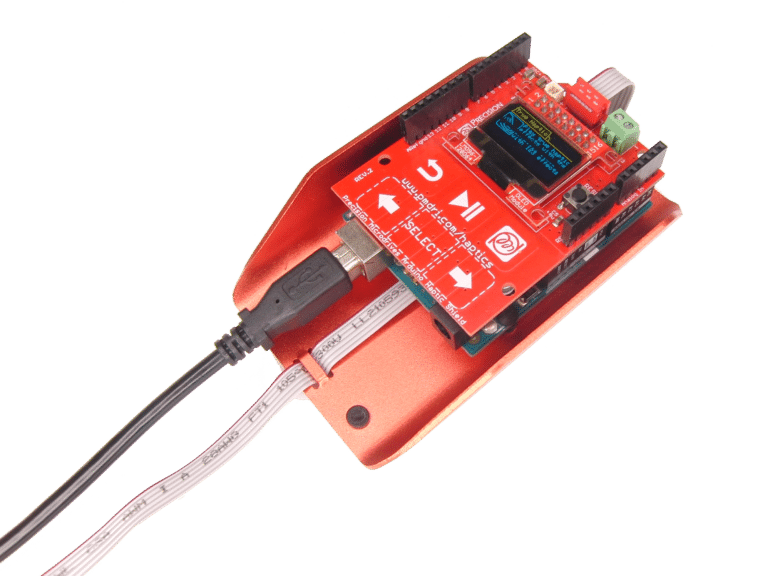

The hotspot explainer below uses our haptic feedback kit to illustrate the main components that make up a typical haptic feedback solution.

-

Touch sensors

These are a sensors or touch surface that you touch. A touch surface microchip registers the touch and it’s location. The touch registration is sent directly (as quickly as possible) to the haptic driver, along with relevant information, such as which area in the touch space was pressed.

-

Suspension

If you attach a vibration motor or haptic actuator to a rigid body, most of its energy will spread away from the touch surface. Suspension exists to isolate the touch area from the rest of the device or application, and keep the haptic feedback energy solely on the touch surface.

-

Application host processor

The application host processor, in our example an Arduino Uno, takes signals from the touch sensor, processes them and then causes the device to react as it’s supposed to do.

What it’s not supposed to do is get in between the touch sensor and the haptic driver. We want the signal from the touch sensor that someone has pressed the touch surface, to be transmitted to the haptic driver as quickly as possible.

-

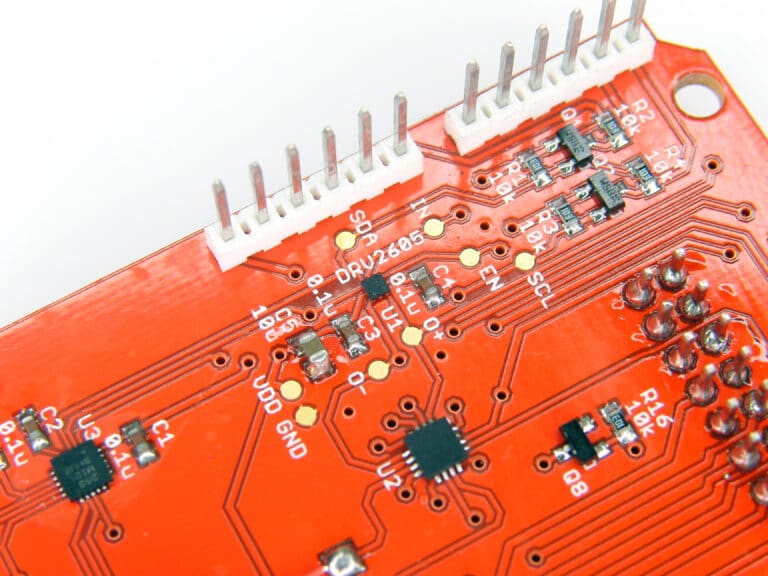

Haptic driver

The haptic driver receives a signal from (ideally) the touch sensor and begins to drive the vibration actuators / motors. The signal from the touch sensor should instruct the haptic driver which haptic effect it should ‘play’ through the actuators.

The actuators will then be driven with a range of signals to accelerate / decelerate them to create the impulse that the user will feel.

-

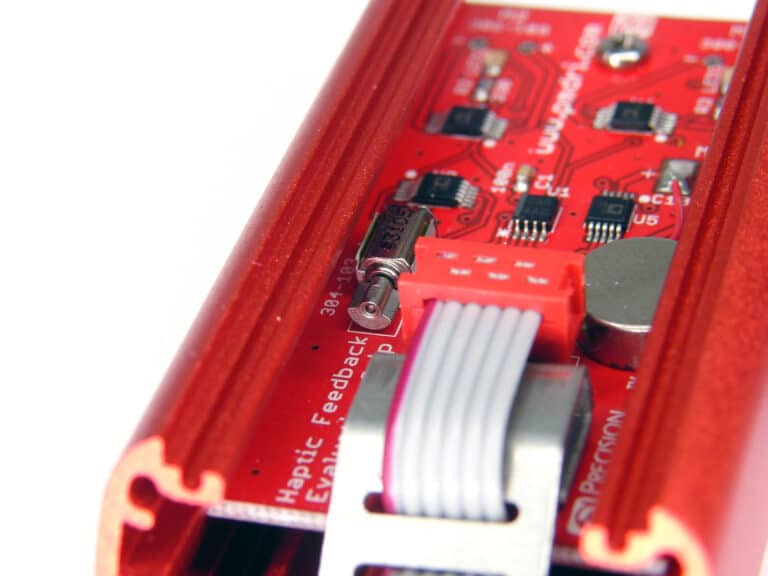

Vibration actuators

The vibration actuators / motors are the components that turn the electrical signals into the vibration / mechanical impulses that the user feels.

Typically they can be ERM, LRA or solenoid type motors.

-

Click on the blue hot-spots, left, to learn more…

This is the Precision Microdrives haptic feedback evaluation kit. It’s a simple device that illustrates the main components and design considerations, that make up a typical haptics application.

NEXT STEPS

Add haptics to your application

We know, how tempting it is to buy a few vibration motors and a DRV2605 – it’s quick and easy, and it will work more often than not. But to add high quality haptic feedback, that’s audibly quiet, and works consistently in the application requires a bit more investment.

Excellent haptics comes from combining the right actuators, the right suspension, a tuneable driver, and good deal of experience in how to bring it all together in such a way that it can be consistently manufactured.

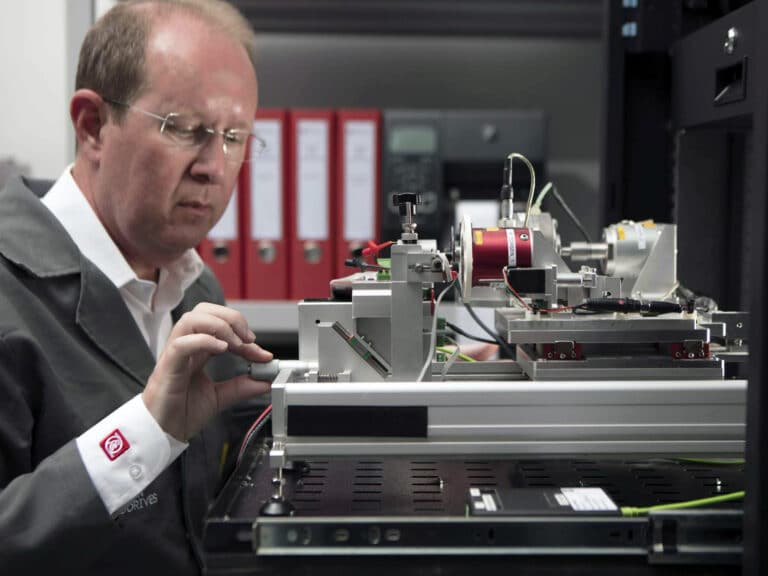

PRECISION PROCESSES

Our capabilities

We can support you through the whole journey from prototype to high volume cost-effective mass production:

Our customers

We’re proud to support all customers large and small. Here are a few of our customers that we have designed and manufactured motors and mechanisms for.

HOW CAN WE HELP?

The Precision Microdrives advantage

Custom Assemblies

Longevity testing

Mechanism design

Engineering confidence

In-house production

Full testing validation

MOTORS & MECHANISMS

More precision products

Verified and reliable precision motors, perfect for your application.

-

Brushless Motors

We offer a comprehensive range of DC brushless motors in both slotted and slotless (high torque and negligible cogging) designs,

View Page

-

Vibration motors

With every vibration and haptic technology covered, we’ll help you select the best vibrating solution for your application.

View Page

-

DC motors

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf

View Page

-

DC gear motors

Building on our range of DC motors, we integrate spur and planetary gearboxes, from 6mm to 60mm frame diameters.

View Page

-

Mechanisms

Custom motor assemblies designed and manufactured to your requirements. A turnkey service from design inputs to mass production.

View Page

-

Linear actuators

Precise, reliable and highly customisable linear actuators designed for a wide range of industrial, commercial and medical applications.

View Page

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.

Case studies

View our past projects with examples of various different applications utilising custom-made motor and mechanism solutions from Precision Microdrives.