Case study

Wearable smart device

- Wearable smart device for crowd control.

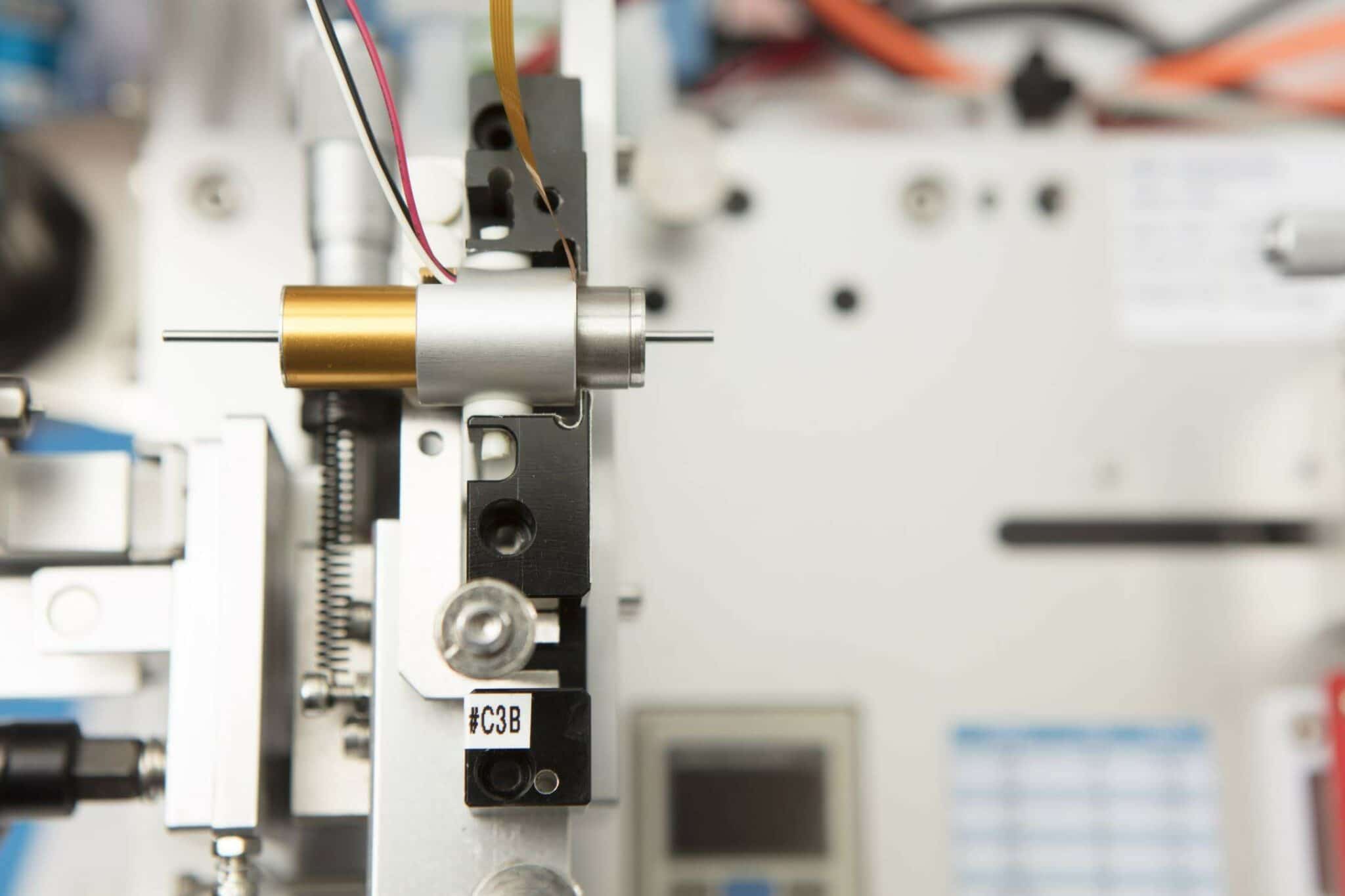

- Surface mounted vibration motor.

- Modified motor bracket to aid assembly.

Challenge

- Our customer designed and developed a wearable smart device.

- The device alerts the wearer using vibration alerting, on queue lengths, priority boarding and purchase options whilst validating tickets/passes.

- The device required low battery drainage, and had to pass a series of strict tests including longevity, shock and moisture.

Solution

- Our customer needed a manufacturer who fully understood their technical challenges.

- With multilingual capabilities in their European time zone, and Asian time zone to aid communication with their Asian contract manufacturer.

- We identified an issue with their assembly process, and were able to provide a speedy solution that resolved the issue.

Results

- We saved our customer from a costly redesign.

- We designed and manufactured a motor that uses minimal power, whilst maximising the device longevity.

- The venues using the product reported an increase in customer satisfaction, an increase in revenue and customer spending across multiple sites.

Project scope

Vibration alerting smart device

The customer approached us whilst they were designing and developing a wearable smart device. The device would be used in various locations, but particularly in busy entertainment venues, theme parks and water parks. The device alerts the wearer on queue lengths, priority boarding, and purchase options whilst validating tickets/passes.

The device required low battery drainage and had to pass a series of strict tests including longevity, shock and moisture. The customer needed a manufacturer who fully understood their technical challenges and crucially had multilingual capability within multiple time zones, to aid communication with their Asian contract manufacturer.

STAGE 1

Designing for application

- We worked with the customer, taking on part of their design responsibility and assigned an in-house team managing their development risk.

- We jointly reviewed their designs, identifying an issue with their proposed motor housing.

- We were able to provide a speedy solution that resolved the issue, whilst maintaining their tight requirements and tolerances.

STAGE 2

Testing and finalising

- This also meant they did not need to redesign their device, make any changes to their tooling/jigs, nor alter their production line that was prebuilt.

- Battery life was critical, so we helped develop and manufacture a motor that uses minimal power whilst maximising the device longevity.

- Intensive in-house testing proved our engineering input, by resolving the design issue for the customer.

STAGE 3

Results and relationship

- The device was launched on time in a variety of different entertainment venues, and has been well received by their target market.

- The venues using it have reported an increase in customer satisfaction, an increase in revenue and customers spending more across multiple sites.

- Our London and Hong Kong based engineering teams fulfilled a critical need in supporting the customer’s in-house design team.

CASE STUDIES

We supply motor and mechanism solutions for all sorts of applications

-

Medical patient simulator

Patient simulator for first-aid cardiac arrest training required a vibration motor to haptic simulate a heartbeat.

View Case Study

-

Swarm robot research linear actuator

Challenging technical and unique application for swarm robotics for a European robotic research Institution.

View Case Study

-

Bench-top pill counting machine

Bench-top medical instrument used a vibration motor to aid movement of pills through instrument pathways.

View Case Study

-

Weather balloon measurement lab

High volumes of low-cost reliable single-use motors for weather balloon measurement lab.

View Case Study

-

Emergency services ruggedised radio

Emergency radios to withstand high temperatures, impacts, and vibrate through protective clothing

View Case Study

-

Surgically implanted pacemaker motor

Brushless vibration motor within a FDA Class III implanted medical pacemaker device.

View Case Study

MORE THAN YOUR AVERAGE MOTOR SUPPLIER

We manage your risk

We manage your risk through optimised design and rigorous testing, protecting your application and intellectual property, fulfilling your performance requirements, whilst reducing your lifecycle costs.

MOTORS & MECHANISMS

Precision products

From off the shelf motor components to fully validated and tested complex mechanisms, choose a motor and mechanism partner you can trust.

-

Mechanisms

Custom motor assemblies designed and manufactured to your requirements. A turnkey service from design inputs to mass production.

View Page

-

Vibration motors

With every vibration and haptic technology covered, we’ll help you select the best vibrating solution for your application.

View Page

-

DC motors

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf

View Page

-

DC gear motors

Building on our range of DC motors, we integrate spur and planetary gearboxes, from 6mm to 60mm frame diameters.

View Page

-

Haptic feedback

Practical and reliable, low noise and high quality haptic feedback solutions for all types of application user interface.

View Page

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies

Industries we serve

At Precision Microdrives we design and manufacture customised electric motors and mechanisms across a number of industries.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help.