Case study

Portable Ventilator

- Very fast and focused help to support triaged development of an emergency portable ventilator.

- Responding to the UK government’s call for support in the face of an unprecedented developing pandemic.

- Precision Microdrives supported UK Formula One teams with motor components for this project.

Challenge

- Unprecedented challenge caused by the COVID-19 worldwide pandemic.

- An amazing opportunity to help develop an emergency portable respirator using our engineering ingenuity.

- The Formula One teams leading the project were trying to ‘bolt together’ an emergency medical device in under a month.

Solution

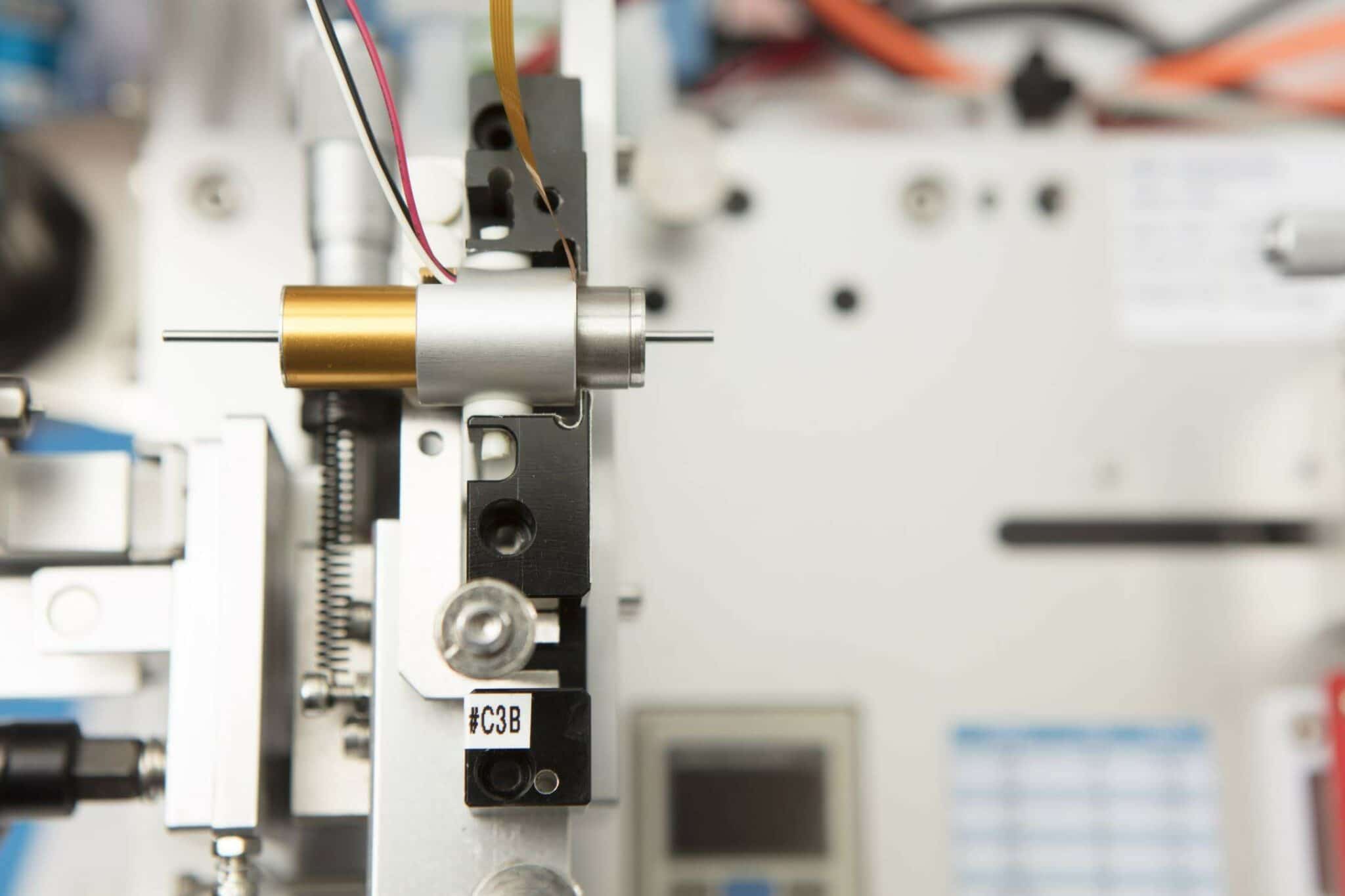

- Our engineering teams in both the UK and Hong Kong prepared a robust DC drive solution that could be validated within a few weeks.

- The motor selected was so chosen because we could pull together an international manufacturing ecosystem to deliver whilst many countries were in strict lockdowns.

Results

- Our DC motor was validated as a key component to the UK’s emergency response ventilator program.

- Our mass production and drive engineering expertise was essential within a knowledge ecosystem of very high performance and low volume manufacturing (Formula One racing).

Project scope

Urgent solution for portable ventilator during COVID-19 pandemic.

In March 2020, little was known about the severity of COVID-19, and everyone was scrabbling to prepare for a very uncertain outbreak of disease. At the time, it was believed that ventilators would be essential to treat patients and with a worldwide demand they were in very short supply.

The UK government issued a request for help from industry, to supply the parts needed to design and manufacture a cost-effective, high volume, portable ventilator medical device. A project that would normally take years of development, had to be designed in the space of weeks.

Most of the Formula One teams, many of whom are based in the UK took the design lead, alongside universities with specialist knowledge. But for all their engineering skills, Formula One companies specialise in hand building a handful of products each year, at any cost. Not mass producing lots of products to a budget.

Admittedly with government backing, that budget was pretty flexible, but the designers still needed expertise in a range of fields, and we volunteered to support with the ventilator motor. To make matters even more challenging, most of the Asian supply ecosystem was shut-down due to the first outbreak there in Jan / Feb 2020.

We worked with the designers and proposed one of our larger DC motors, which co-incidentally we had enough of a stock holding, to get the projects started. This would cover all the validation testing whilst we worked to build an worldwide ecosystem of equivalent part suppliers, including our competitors.

Within a month (April 2021), the design leads, with our support, had pretty much finished a viable design which had passed rapid validation testing. The DC motor did have a limited lifetime compared to say a brushless variant, but it was much more viable for us to supply this in the expected volumes, by stringing together bits of the supply chain that were still working.

Alas, our save-the-day design, wasn’t meant to be. By May, it was clear that COVID wasn’t as deadly as originally feared, and the need for emergency ventilators was downgraded, putting all the projects on hold.

STAGE 1

Engineering expertise

- The UK government had an urgent need to bring together experts in a wide range of engineering fields, to create a ‘bolted together’ emergency medical ventilator.

- We partnered with leading Formula One racing teams to support development of the main motor drive, with a selection deadline of mere days.

- The engineering expertise we delivered went beyond motor engineering as we were also able to advise on design for mass production aspects.

STAGE 2

Testing and validation

- We delivered a DC motor suitable for both validation and mass production from our UK stocks.

- This motor was carefully chosen because we would be able to continue production from an international component supply-chain, thereby avoiding factory shut-downs / lock-downs in many countries with a motor supply ecosystem.

- The motor whilst not being optimised for long-life, was proven to be perfectly adequate for the expected lifetime of the emergency portable ventilator.

STAGE 3

Results and relationship

- Our project partners were able to answer the UK government’s call to supply a mass producable and cost effective portable ventilator with little over a month’s development time.

- The Formula One teams we supported were impressed with our response time and the standard of engineering expertise we were able to deliver.

- Thankfully the disease was not as severe as feared and these extra ventilators were never needed. Nevertheless, the experience was positive and our team were very proud to have supported the effort.

CASE STUDIES

We supply motor and mechanism solutions for all sorts of applications

-

Medical inhaled medication delivery device

Intelligent medical inhaler device, which was FDA Class III approved, required a gear motor mechanism to provide precise

View Case Study

-

Medical patient simulator

Patient simulator for first-aid cardiac arrest training required a vibration motor to haptic simulate a heartbeat.

View Case Study

-

Swarm robot research linear actuator

Challenging technical and unique application for swarm robotics for a European robotic research Institution.

View Case Study

-

Bench-top pill counting machine

Bench-top medical instrument used a vibration motor to aid movement of pills through instrument pathways.

View Case Study

-

Weather balloon measurement lab

High volumes of low-cost reliable single-use motors for weather balloon measurement lab.

View Case Study

-

Surgically implanted pacemaker motor

Brushless vibration motor within a FDA Class III implanted medical pacemaker device.

View Case Study

More than your average motor supplier

We manage your risk

We manage your risk through optimised design and rigorous testing, protecting your application and intellectual property, fulfilling your performance requirements, whilst reducing your lifecycle costs.

MOTORS & MECHANISMS

Precision products

-

DC motors

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf

View Page

-

DC gear motors

Building on our range of DC motors, we integrate spur and planetary gearboxes, from 6mm to 60mm frame diameters.

View Page

-

Vibration motors

With every vibration and haptic technology covered, we’ll help you select the best vibrating solution for your application.

View Page

-

Haptic feedback

Practical and reliable, low noise and high quality haptic feedback solutions for all types of application user interface.

View Page

-

Mechanisms

Custom motor assemblies designed and manufactured to your requirements. A turnkey service from design inputs to mass production.

View Page

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies

Industries we serve

At Precision Microdrives we design and manufacture customised electric motors and mechanisms across a number of industries.

About PMD

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help.