Case study

Electric lock mechanism for emergency exits

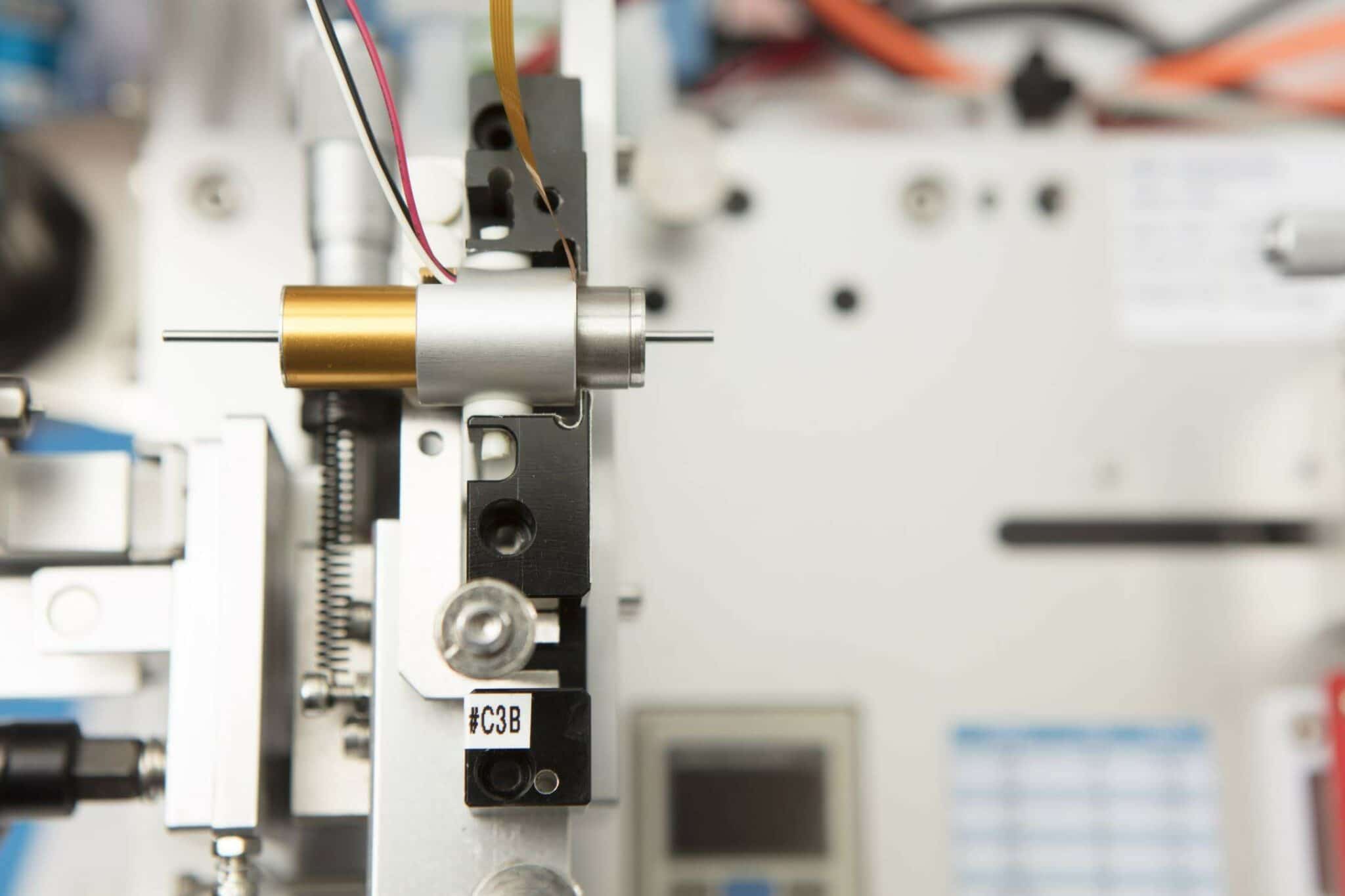

- Electric lock mechanism for ‘panic bars’ on emergency exits doors.

- 25mm gearmotor used in the push bar mechanism.

- Designed so the mechanism can be retrofitted to any emergency door.

Challenge

- Our customer approached us when they were tasked with sourcing a suitable gear motor for a new electric lock mechanism, designed to be used in ‘panic bars’ on emergency exit doors.

- The motor needed to be robust and have a long lifetime due to the life-saving situations the product was going to be used in.

Solution

- We reviewed the designs and suggested we begin by testing a spur gearmotor.

- Our customer rigorously tested this motor and it transpired that it wasn’t strong enough for the intended load so wouldn’t perform well in an emergency situation.

- Based on the feedback we received, a planetary gearmotor was then recommended as this is a stronger motor and is more effective with high speed so would have a quicker reaction time.

- We provided a selection of cost-down initiatives that supported the customer and reduced the overall cost of the lock system.

Results

- The new lock was launched onto the market and has had several years of consistent sales and good customer feedback.

- As the demand for the lock has grown we have supported our customer in scaling up production, as well as helping them out when they have had periods of sudden high demand including a special order for a new residential development project.

- The range of electric door locks was extended and Precision Microdrives now supplies gear motors for an expanded collection of electric locks.

Project scope

Electric door lock mechanism for ‘panic bar’ emergency exit doors.

Our customer was tasked with sourcing a suitable gear motor for a new electronic lock mechanism that had been designed specifically for emergency exit doors.

The concept was a mechanism that could reverse the push lever on the door and allow the emergency services instant access to the building without the need for additional equipment or breaking down the door. It could also be connected to a building’s access system and this would allow it to be programmed to automatically release/open in the case of an emergency. This would save valuable time and increase the chances of survival for anyone trapped inside the building.

The mechanism was designed so it could be installed with a new emergency door or retrofitted to an emergency exit as part of a building upgrade program. This meant that when the lock was launched it was well-received by both the building/construction and property management industries.

Our customer subsequently launched an expanded range of electric locks onto the market and Precision Microdrives continues to support them throughout their collection.

STAGE 1

Designing for application

- Our customer was looking for a robust gearmotor that would be strong enough to work in an emergency but would not be large and bulky. The lock was going to be used in a variety of different settings including prestigious office developments, hospitals and airports so needed to look stylish as well as be functional.

- The lock mechanism needed to be able to withstand changes in temperatures as it would be mounted on external doors that would be exposed to a wide variety of weather conditions when the door was opened.

- They had a clear idea of the strength of gearmotor they were looking for, but lacked the knowledge on the type of motor they needed. We reviewed the specification and suggested a couple of different types of gearmotors for them to test.

STAGE 2

Manufacturing and testing

- We supported our customer as they tested a selection of different types of gearmotors. We found a planetary gearmotor that met all their requirements and would release the door latch within two seconds.

- Our customer performed temperature, environmental and mechanical tests, to ensure the motor would perform as expected in a variety of different conditions.

- We also tested the lock to ensure it would be compatible with most building access control systems as wanted to enable buyers to be able to integrate it into their building controlled access systems.

- Once the motor had been thoroughly tested and the prototype had passed all its checks, the device went into full production.

STAGE 3

Results and relationship

- The lock was certified as BS EN1125:2008, fire-rated and awarded the CE mark for safety and peace of mind.

- We have agreed on a flexible manufacturing agreement as this reduces their supply chain risk when their needs change.

- Now owned by an international door hardware manufacturer who have expanded the range of electronic locks and continued to engaged us to support them with this growth.

CASE STUDIES

We supply motor and mechanism solutions for all sorts of applications

-

Medical patient simulator

Patient simulator for first-aid cardiac arrest training required a vibration motor to haptic simulate a heartbeat.

View Case Study

-

Swarm robot research linear actuator

Challenging technical and unique application for swarm robotics for a European robotic research Institution.

View Case Study

-

Bench-top pill counting machine

Bench-top medical instrument used a vibration motor to aid movement of pills through instrument pathways.

View Case Study

-

Weather balloon measurement lab

High volumes of low-cost reliable single-use motors for weather balloon measurement lab.

View Case Study

-

Emergency services ruggedised radio

Emergency radios to withstand high temperatures, impacts, and vibrate through protective clothing

View Case Study

-

Surgically implanted pacemaker motor

Brushless vibration motor within a FDA Class III implanted medical pacemaker device.

View Case Study

MORE THAN YOUR AVERAGE MOTOR SUPPLIER

We manage your risk

We manage your risk through optimised design and rigorous testing, protecting your application and intellectual property, and fulfilling your performance requirements, whilst reducing your lifecycle costs.

MOTORS & MECHANISMS

Precision products

From off the shelf motor components to fully validated and tested complex mechanisms, choose a motor and mechanism partner you can trust.

-

DC motors

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf

View Page

-

DC gear motors

Building on our range of DC motors, we integrate spur and planetary gearboxes, from 6mm to 60mm frame diameters.

View Page

-

Vibration motors

With every vibration and haptic technology covered, we’ll help you select the best vibrating solution for your application.

View Page

-

Haptic feedback

Practical and reliable, low noise and high quality haptic feedback solutions for all types of application user interface.

View Page

-

Mechanisms

Custom motor assemblies designed and manufactured to your requirements. A turnkey service from design inputs to mass production.

View Page

-

Linear actuators

Precise, reliable and highly customisable linear actuators designed for a wide range of industrial, commercial and medical applications.

View Page

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies

Industries we serve

At Precision Microdrives we design and manufacture customised electric motors and mechanisms across a number of industries.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help.