Vibration Motors and Haptic Feedback

Wide range of DC vibration motors with off-the-shelf sampling

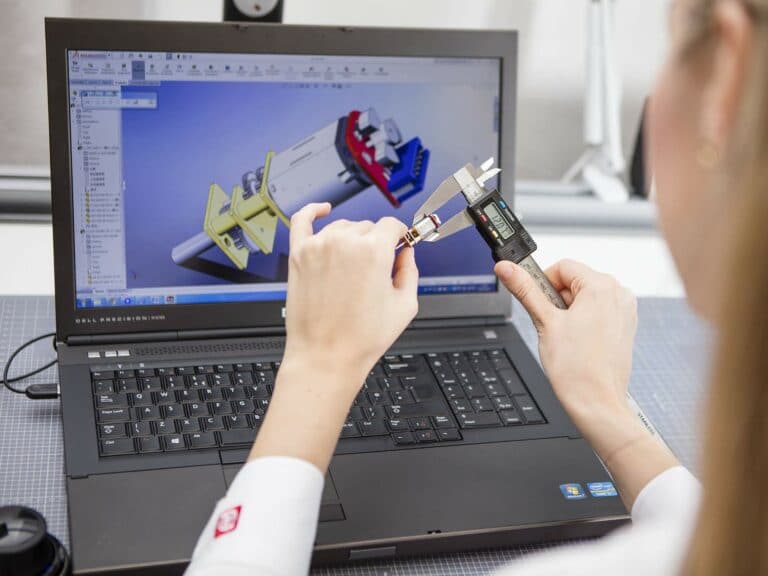

Expedite your product development

with miniature vibration motors, mechanisms and haptic feedback technology designed for your application

Trust Precision Microdrives to manage your development and manufacturing risks

Using our proven technology and design process, we engineer cost-effective, multi-volume motor and mechanism solutions you can rely on. Freeing up your engineering resource to expedite your R&D.

- Consistent, reliable, quality controls

- Managing your engineering risk

- Motor products delivered On Time and To Spec

- Expedite your product development

- Free up your internal resources for more valuable R&D

- Design, validation and compliance processes to rely on.

Speak to an engineer

DESIGN SOLUTIONS

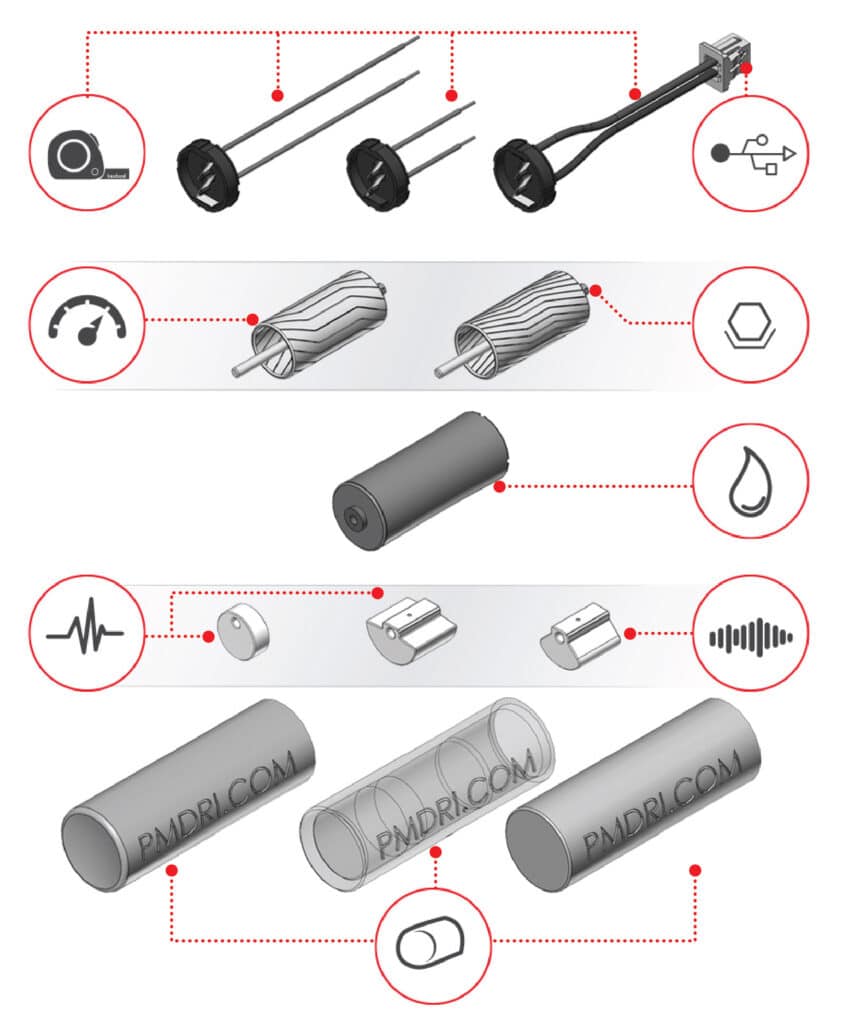

Technologies and form factors

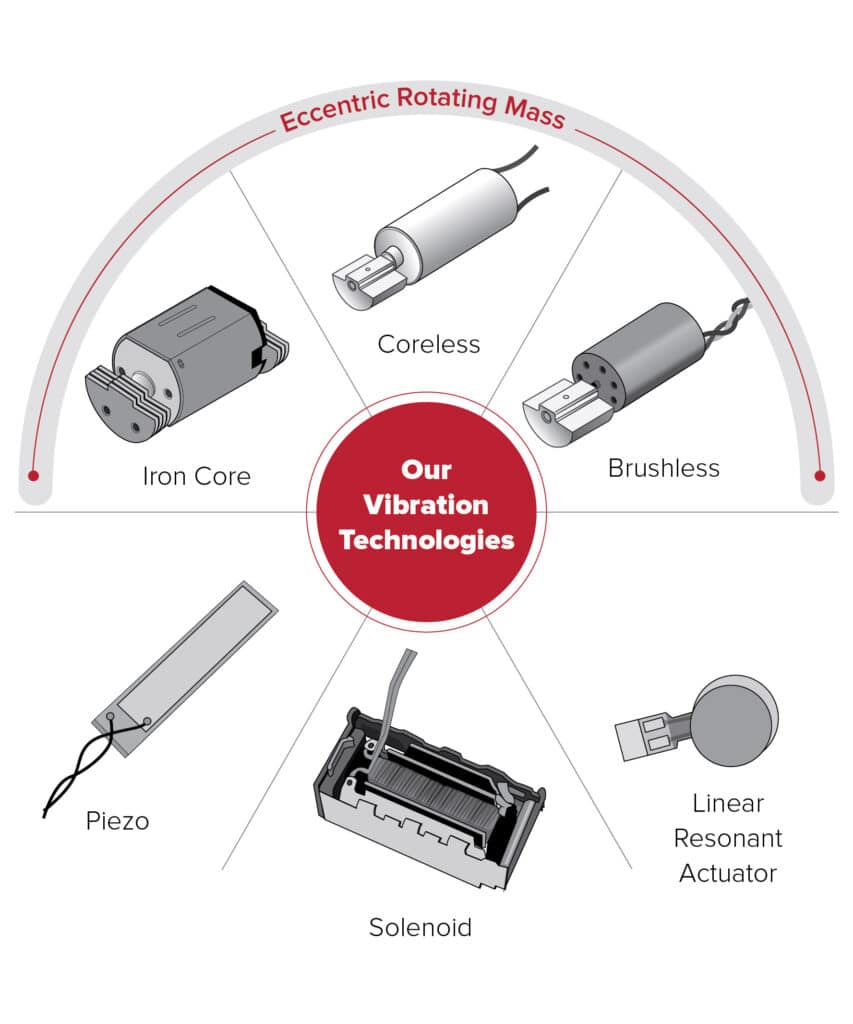

Vibration motor technologies

Our application engineers design vibration and haptic feedback solutions using six distinct motor technologies.

- Eccentric Rotating Mass (ERM)

- Linear resonant actuators

- Solenoid actuators

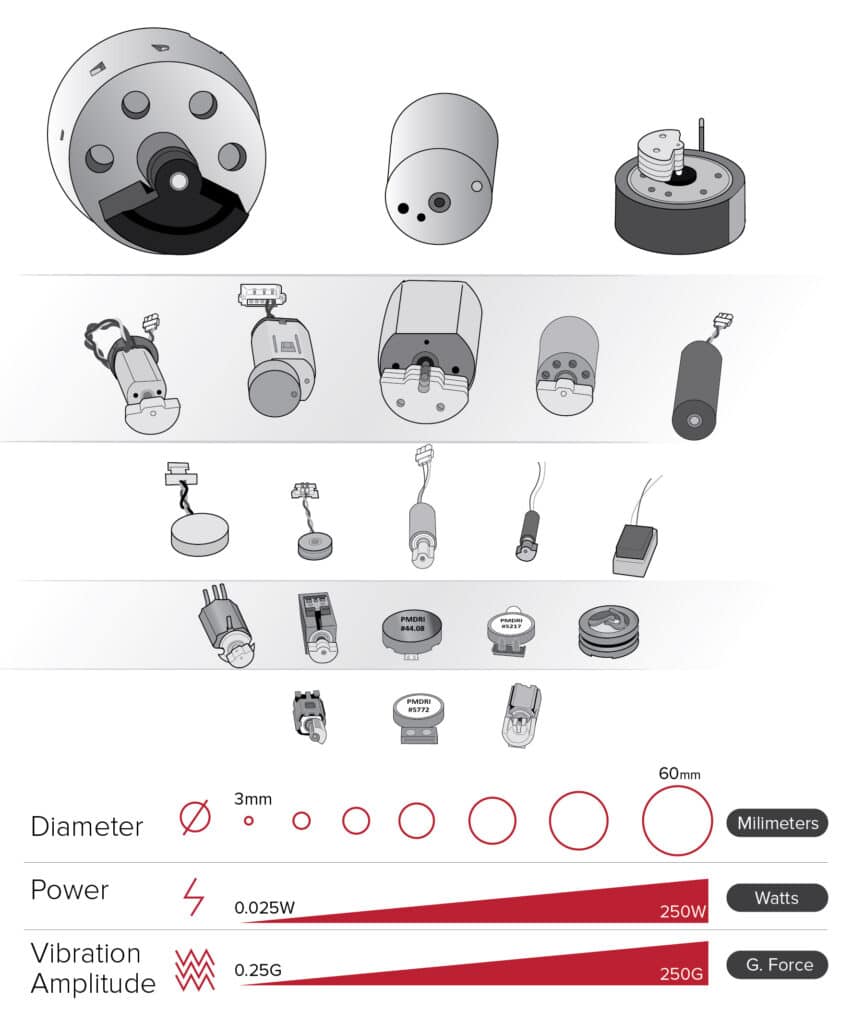

57 stocked motor form factors

We want to help get you developing quickly. So we have many off-the-shelf form factors in a variety of winding configurations available for sample or purchase.

- Leaded vibration motors

- Through hole PCB vibration motors

- SMD reflow vibration motors

- Coin and pancake vibration motors

- Encapsulated vibration motors

Customisations

Your application is unique so we expect you to want some level of custom features or performance. Work with our application engineers to design the perfect solution.

- Lead customisation

- Connectors

- Brushes and commutator

- Bearings and lubricants

- Resonant vibration frequencies

- Encapsulation

- Eccentric mass modification

- Winding customisation

Typical vibration motor form factors

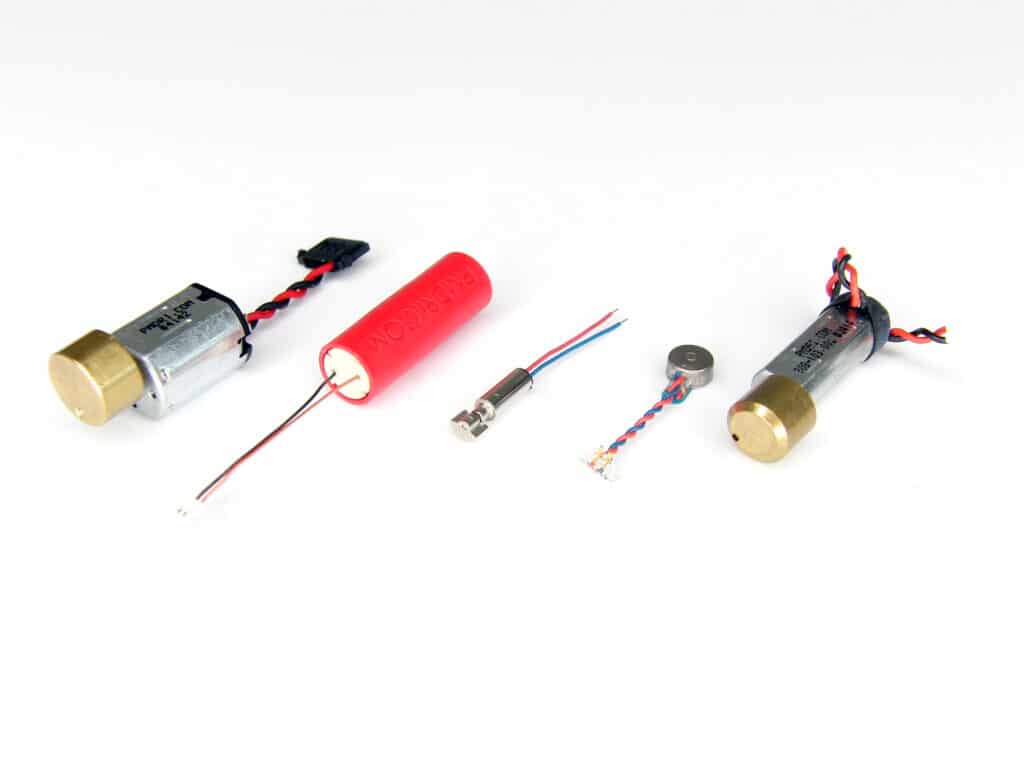

Leaded vibration motors

Most vibration motors come with pre-fitted wires / leads that can be modified to length and fitted with a wide range of connectors.

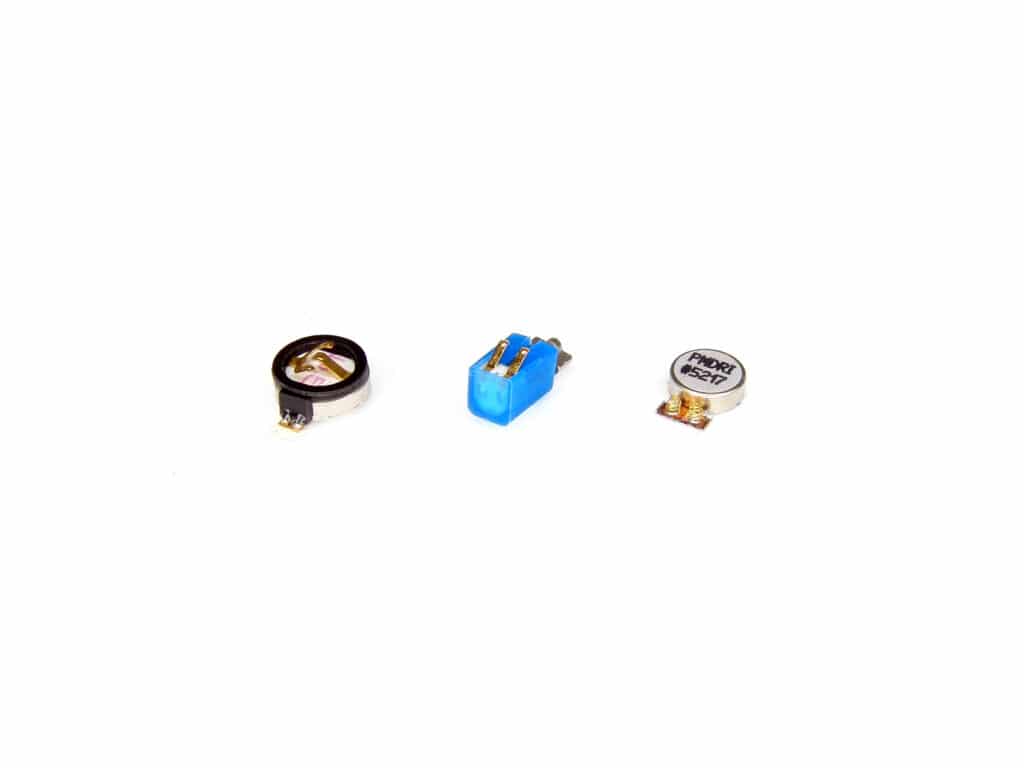

Through hole PCB vibration motors

Some vibration motors can be through-hole PCB mounted, and within this category, we can send power through pins or wires / leads

SMD reflow vibration motors

We offer a wide range of SMD reflowable vibration motors that are supplied on SMD pick and place reels.

Spring pad vibration motors

For cases where the motor should be integrated into the case, rather than PCB, spring pad motor designs are a good choice.

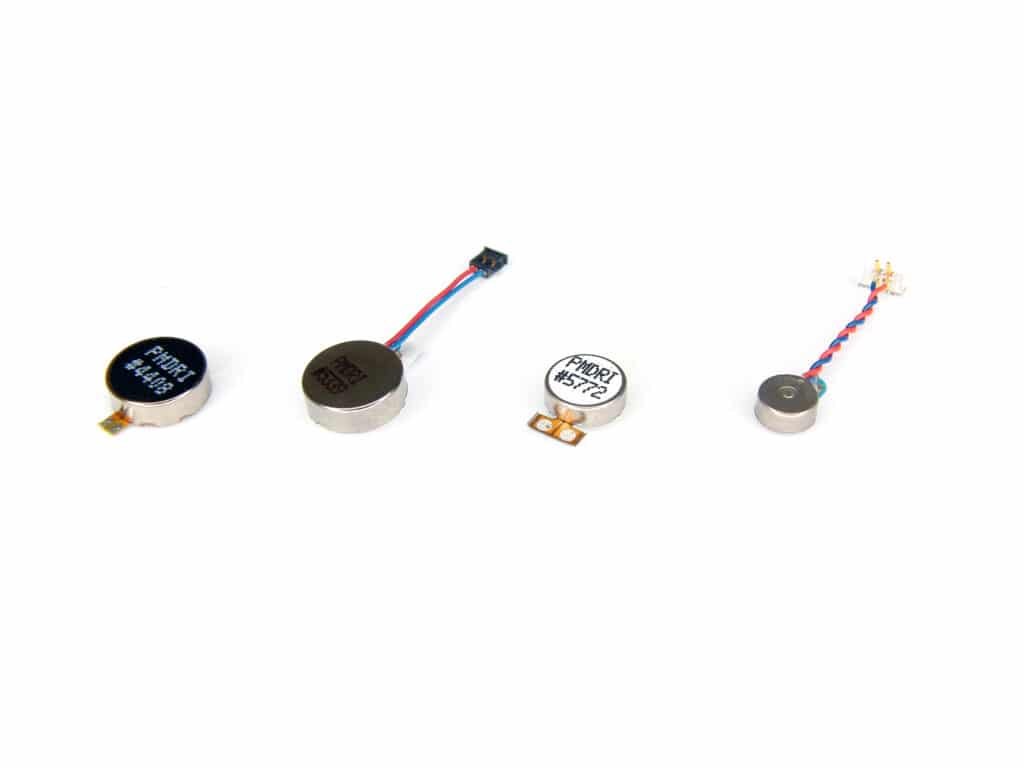

Coin and pancake vibration motors

We carry a wide range of ERM and LRA motors in both coin or ‘pancake’ designs. These can be leaded or fitted with pad springs.

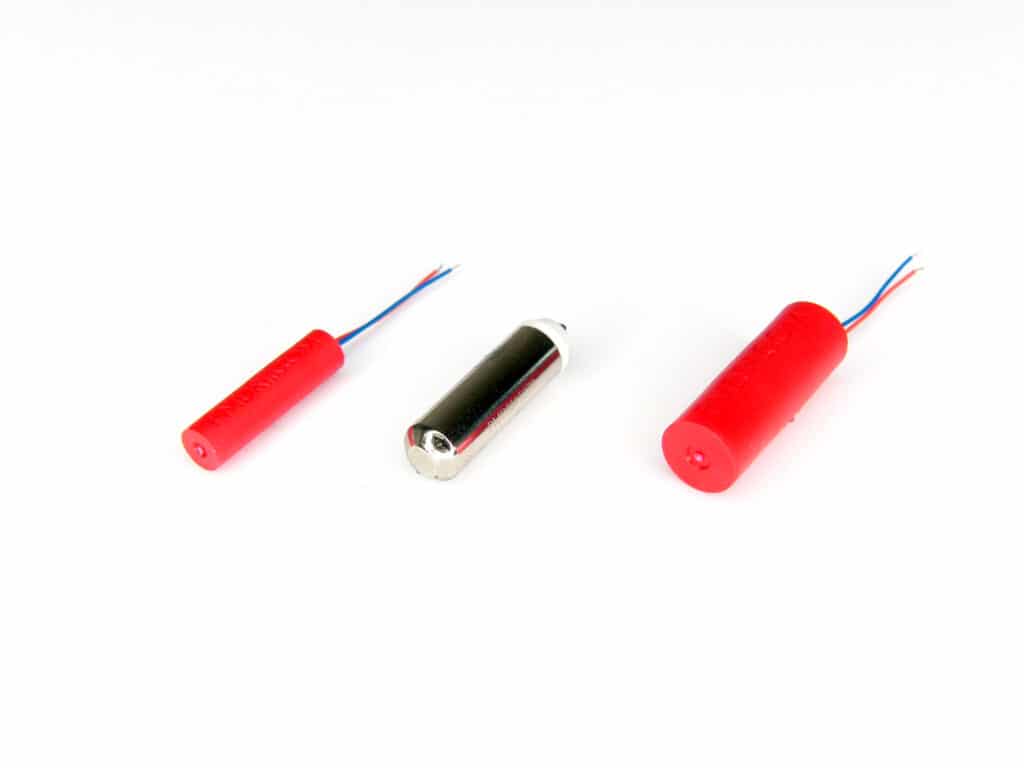

Encapsulated vibration motors

If ERM clearance is an issue, or over-moulding is desired, try our range of encapsulated vibration motors.

WHAT YOU NEED

Haptic feedback or vibration alerting?

Haptic Feedback

Haptic feedback uses very controlled vibration or actuated movement, to provide touch feedback or information to a user. It is a tactile user interface and enables a device to speak the ‘language’ of haptics, adding complexity.

The most obvious implementation of this is a touch screen, where haptic feedback takes the form of simulating the feeling of pressing a button.

A more complex example would be a glove with many haptic actuators on it to support training of a surgeon in a virtual reality environment.

Vibration alerting

Vibration alerting is a lot simpler. It’s a binary on / off signal to a user to grab their attention.

Think of an incoming phone call, vibration on a steering wheel to alert the driver that they have veered across a lane marking, or a vibrating crane control stick to signal that the attached load is too heavy.

Vibration alerting can also be quite elaborate – think of a belt with 12 integrated vibration motors to direct the wearer where to go. Most people call this haptics, but it’s actually just vibration alerting.

Why the big deal with semantics? Well in a nutshell, if you’re vibration alerting the project is going to be much simpler and cheaper.

Find out more about our range of vibration technology

MORE THAN YOUR AVERAGE MOTOR SUPPLIER

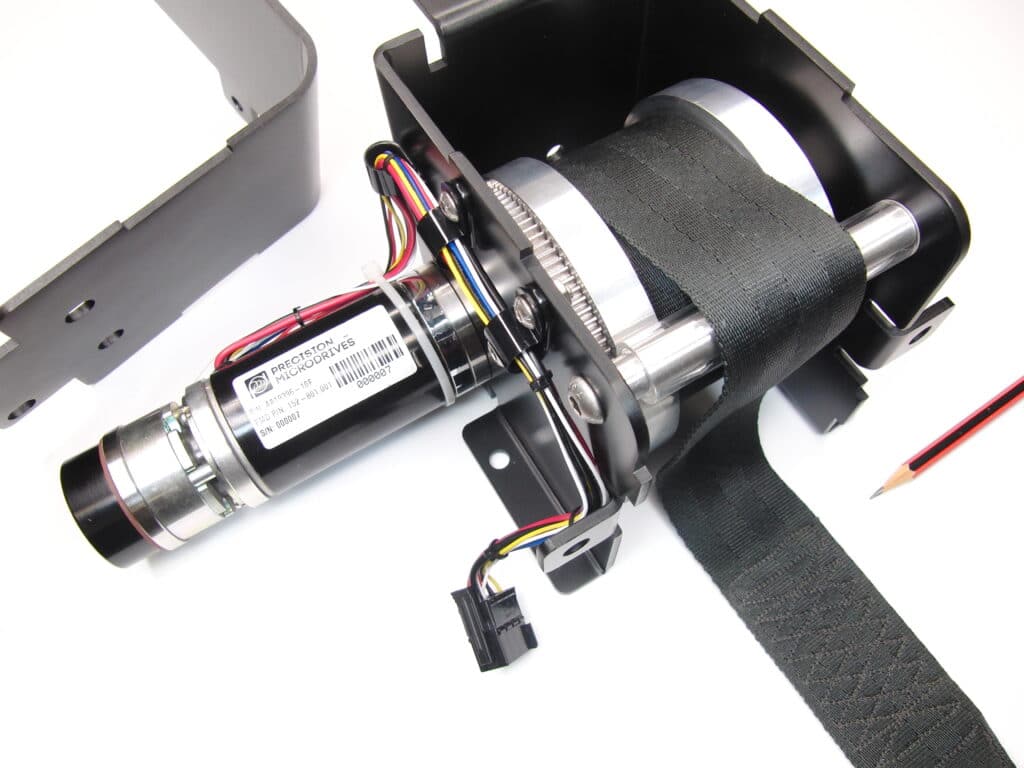

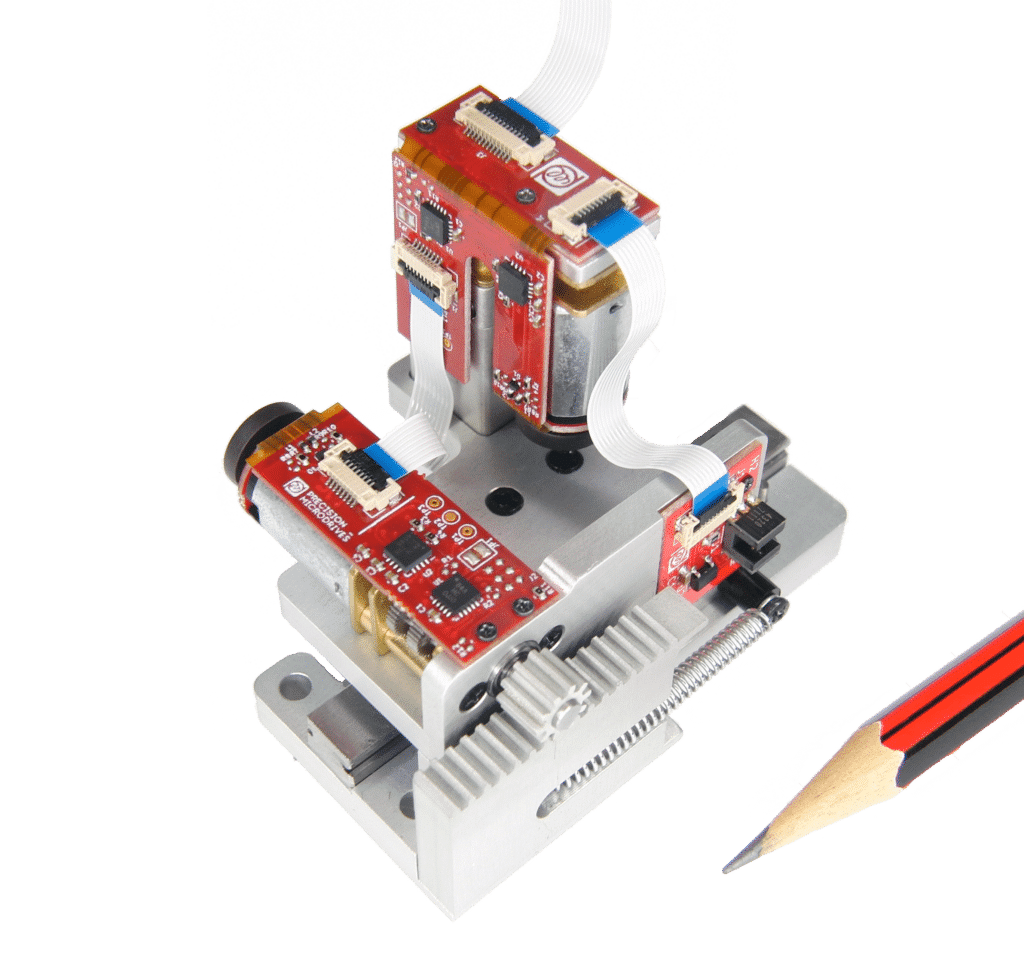

Specialised engineering services and capabilities from Precision Microdrives

YOUR MOTOR ENGINEERING PARTNER

Why Precision Microdrives?

Trusted motors and mechanisms

Getting the core of your application correct, first time

Motors and mechanisms are likely one of the most expensive lines on your BOM and also the least likely to be noticed by your customers. Until they fail…

So, choose an engineering partner that has extensive domain expertise in mitigating the technical risks of these complex products.

Rely on a manufacturing partner with a presence on the ground, robust quality control processes, and a familiar approach to maximising your value-add.

Priced to deliver the best value

We engineer our products to be optimised for your application and delivered at a best value cost.

We don’t engineer our solutions to the highest possible standards, or the lowest possible costs.

That’s not the only way we help your profitability either.

Add a very technically experienced, cost effective addition to your development team. We will free up your internal resource to focus on more valuable R&D work, which will expedite your development cycles.

Working with Precision Microdrives

Manufacturable design

- We design solutions that are manufacturable and reliable.

- Tested and validated for longevity, performance and environment.

Technical expertise

- Absolute domain experts in motors and mechanisms.

- If we can help by sharing our expertise and experience, we will.

Robust quality controls

- Quality teams in Asia to control upstream component suppliers.

- QC methods developed specifically for motors and sub-components.

Precision manufacturing

- Uniquely (for Asia) co-locating design engineers and final assembly lines in Hong Kong.

- Specialisation in complex electromechanical assemblies.

- Motor / mechanism custom end-of-line testing.

Partnership

- We free up your resources and take away the pain of motor mechanisms for higher value R&D.

- Working as an extension of your business, at every stage.

- Pre and post sales support, in your time zone and language.

Managing your risk

- Unparalleled motor mechanism experience, enables us to predict problems and provide solutions.

- Competent skills and processes to mitigate risks from design through to mass production.

- A culture to get things right!

Key markets and applications

We provide motor and mechanism solutions to all sorts of industries, including:

Medical

- Point of care machines

- Lab analysis and diagnostics equipment

- Drug dispensers

- Automated test platforms

- Pumps

- Surgically implanted devices

Instruments

- Monitoring and measuring devices

- Lab sample preparation equipment

- Diagnostics equipment

- Sensors and gauge testing

- Bench-top dispensary equipment

- Electronics test equipment

Industrial

- Emergency services equipment

- Analysis and monitoring devices

- Transport and logistics

- Controllers

- Ticket kiosks and ATM’s

- Robotics and artificial limbs

Consumer

- Touchscreens and smart devices

- Video games and controllers

- Smart homes

- Automotive dashboards

- E-bikes

Security

- Sensors and alarms

- Handheld scanners

- Surveillance cameras and monitors

- Locks, security systems and safes

- Passport readers and ID scanners

Healthcare

- At home health monitoring

- Rehabilitation accessories

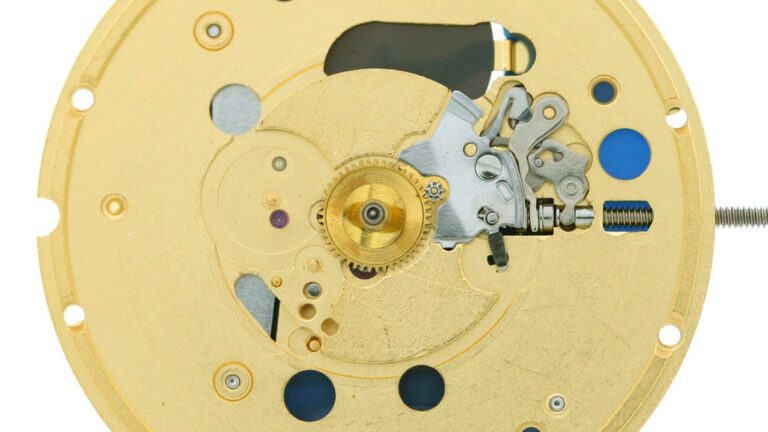

- Fitness trackers and smart watches

- Oral drug dispensaries and vapes

- Stairlift and mobility solutions

Case studies

Our vibration motors are used throughout many applications and industries. Here are some of our recent projects:

-

Handheld barcode scanner

Next generation, multi-purpose, handheld barcode scanner required a new vibration motor solution for alerting and haptic feedback

View Case Study

-

Haptic feedback for Vape

An LRA haptic feedback solution for a new range of vapes.

View Case Study

-

Insulin monitoring device

High quality, reliable Precision Microdrives vibration motor design for FDA Class II diabetic insulin pump.

View Case Study

-

Luxury European smart watch

Luxury consumer smart watch uses a Precision vibration motor to provide haptic feedback to the customer.

View Case Study

-

Road traffic crossing system

Our customer manufactures road traffic crossing systems, which in the UK, have a haptic feature for visually impaired users.

View Case Study

-

Wearable Cardioverter Defibrillator Vest

Our client required a fully encapsulated medium powered vibration motor for tactile vibration alerting FDA approved wearable cardioverter defibrillator (WCD) vest, for patients who are at risk of Sudden Cardiac

View Case Study

-

Wearable smart device

Our client designed and developed a wearable smart device using a vibration motor for alerting.

View Case Study

-

Medical patient simulator

Patient simulator for first-aid cardiac arrest training required a vibration motor to haptic simulate a heartbeat.

View Case Study

-

Bench-top pill counting machine

Bench-top medical instrument used a vibration motor to aid movement of pills through instrument pathways.

View Case Study

-

Surgically implanted pacemaker motor

Brushless vibration motor within a FDA Class III implanted medical pacemaker device.

View Case Study

-

Emergency services ruggedised radio

Emergency radios to withstand high temperatures, impacts, and vibrate through protective clothing

View Case Study