Using DC Motor Commutation Spikes To Measure Motor Speed RPM

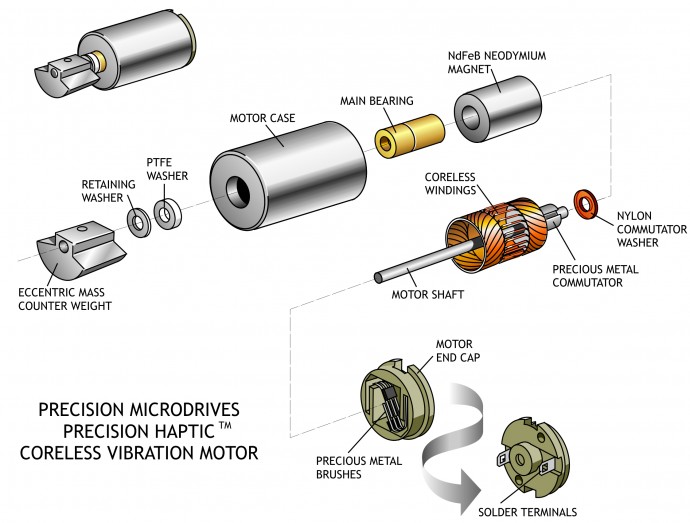

As the armature of a DC motor rotates, an electrical voltage spike is generated every time a brush moves from one commutator segment to the following. It’s called commutation spike and can be used to determine the speed that the motor is rotating at without an encoder. Referring to the diagram below might be useful to follow the rest of this discussion.

DC motor commutation spikes

The commutation spike is the interference on the motor supply voltage due to the quick discharge of the magnetic field stored in a motor winding. This happens when the brush breaks the contact with the commutator sector connected to the energized winding. Usually, this needs to be suppressed to avoid electromagnetic interference (EMI) with a capacitor, and avoid damage to switching semiconductors, usually with a flyback diode.

The number of spikes per revolution is equal to twice the number of sectors of the commutator. In the case of three-pole motors, six commutation spikes per revolution are generated, three per brush. These spikes are a problem for big DC motors, where the EMI causes a lot of problems, while they are almost negligible for very small motors.

The commutation spikes can be used to measure the motor speed. They can be picked up by an oscilloscope, while a high pass filter is usually needed to read them with a pulse counter. Knowing the frequency of the spikes (Fs) and the number of poles (P) of the motor, it’s easy to calculate the motor speed as: 𝑆𝑝𝑒𝑒𝑑=60×𝐹𝑠𝑃

In a real case, due to possible imperfections of the commutator symmetry, it’s preferable to measure the period (T) between 2*P number of spikes and calculate the speed as: 𝑆𝑝𝑒𝑒𝑑=60𝑇

In the figure above, there is an example of this time measurement; the waveform shown is the voltage across the motor. In this case, the motor had 3 poles, so the period measure was between six commutation spikes. All the spikes are clearly visible and looking at the voltage waveform it’s usually easy to verify the number of poles since every 2*P spikes the waveform repeats itself. 𝑆𝑝𝑒𝑒𝑑=600.00872=6880𝑅𝑃𝑀

The commutator spikes are often much easier to see when resistance is put in series with the motor because using a regulated power supply, this will try to keep a constant voltage, flattening out the spikes. The resistance instead will let the motor voltage vary depending on the current flowing through the series.

The measurement of the motor speed using the commutation spikes is also useful to calculate the gear ratio of a gear DC motor. The gear ratio is the relationship between DC motor speed and output shaft speed. The output shaft speed can be easily measured with a tachometer, while, the motor speed can only be known reading the commutation spikes, or adding a tacho to the rear shaft (assuming there is one!).

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.