Eccentric Rotating Mass Vibration Motors – ERMs

Looking for our Haptics range? View our main Haptics hub here.

Eccentric Rotating Mass vibration motors, also commonly known as ERMs or pager motors, make up our main product lines and have been our core business since Precision Microdrives was founded. They shot to popularity with use in pagers and have grown alongside the mobile / cell phone industry, where they are still extremely popular in smartphones. Now there is a wide range of applications that use these tiny vibration motors to offer vibration alert notifications and haptic feedback.

Miniature DC vibration motors have the benefit of being easy to implement and are low cost, whilst dramatically augmenting how devices interact with users. For example, industrial equipment is often used in environments where seeing or hearing a visual or audio alert can be difficult – a small vibration motor can be integrated into a design so that equipment operators and users can rely on the sense of touch, no longer requiring line of sight or high volumes. This is one of the obvious benefits of mobile phones, you can receive notifications when the device is in your pocket without disturbing those around you.

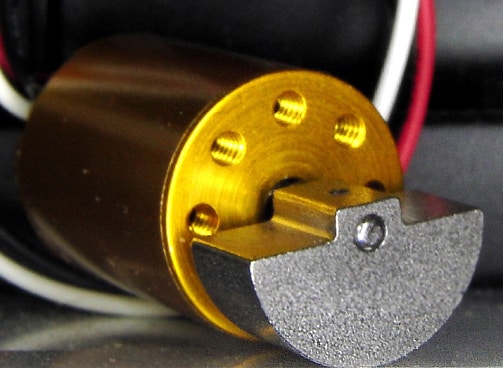

All pager motors use miniature Eccentric Rotating Masses, and hence they tend to be abbreviated ‘ERM motors’. ERM pager motors rely on the rotation of an unbalanced load to create vibration effects and are more recently being used for haptic feedback as well as vibration alerting:

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Our Pico Vibe™ range is designed to be used for handheld equipment in the weight range of around 25 ~ 200 g (1 – 7 oz.). Typically based on DC motors up to 6mm (although some are slightly larger, especially when encapsulated in housing), they normally range from 1.5V to 3V Rated Voltage – which makes them ideal for battery power supplies. The combination of voltages makes these motors suitable for single/double cell power buses of Alkaline, Zinc, Silver Oxide and single cell Lithium primary sources, NiCd, NiMH, Li-ion secondary rechargeable batteries.

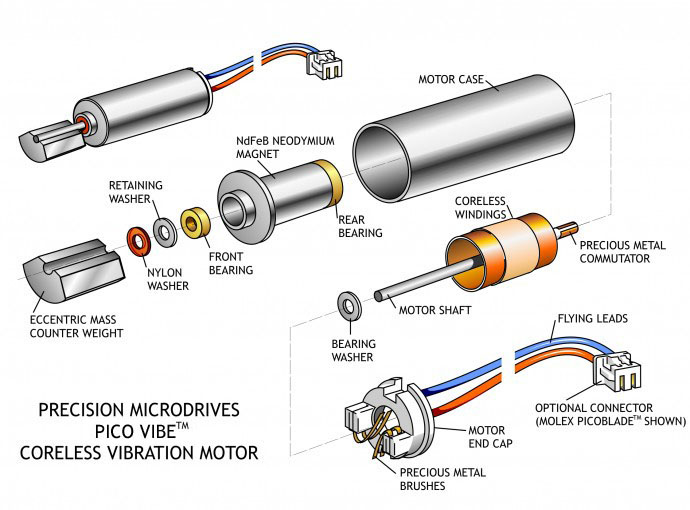

Pager motors in the Pico Vibe™ range are based on a brushed coreless cylinder design and contain powerful NdFeB Neodymium magnets for an improved magnetic flux circuit.

Electrical connections are most commonly made with flying leads, and for larger orders, we can customise lead lengths and add a range of connectors as specified. Our pager motors also come in a number of other form factors that make retrofit and design integration easier.

ERM Vibration Motor Advice

The eccentric rotating mass is the operating principle for most vibration motors, with the exception of linear resonant actuators. If you want to learn more we have lots of application bulletins that cover this in detail. A great starting point is our Video Application Bulletin 02: How do Vibration Motors Work?

ERMs are such a popular base design that we have made them available in a wide range of form factors to suit all kinds of applications. For example, although coin vibration motors look dramatically different externally, they still rotate an internal eccentric mass to create an unbalanced force. Their design makes them very low profile and the eccentric mass is protected, however, this means their vibration amplitude is limited. There are design trade-offs for each form factor, you can read about our most popular ones below:

Applications For ERM Pager Vibration Motors

Miniature ERM Motors are used almost exclusively for vibration alerting and haptic feedback. Therefore, in essence, any machine or application that uses sound or light to offer user/operator feedback could be further enhanced with a vibration motor.

Integrating pager motors into a design isn’t hard, but there are some tips and tricks that we’ve developed along the way which will save time and effort if you follow them – see our application notes page for all the titles. Also, bear in mind that our application engineers will be only too happy to help advise on the best way to introduce a vibration generation function or a haptic feedback feature to your products. You can reach them here.

Examples of recent projects that we’ve integrated vibration motors into include:

- Pagers

- In cell / mobile phones

- Tablet PCs

- Handheld medical instruments

- Industrial tools and industrial user interfaces

- Other personal notification devices, such as watches or wristbands

- Automotive displays/dashboards

Summary

We offer many different vibrating pager motors in a variety of different form factors to suit a very wide range of application usage scenarios. Their small size and low power requirements, allow them to be easily implemented in handheld devices. In addition, a wide range of simple motor drive circuits can be implemented, the addition of haptic feedback or vibration alert is an easy feature to create a competitive advantage over competitors.

Remember also that we sell 1+ quantities of stock pager motors shown below. If you’re looking for larger quantities, please contact us and with the part number and quantity and we’ll reply with a quote by return.

If you need vibrator motors that are a little larger, please follow this link for a full listing of our vibration motors.

Finally, remember that we can modify vibration motors and other parts to meet specifications and customised designs, if you can’t find what you are looking for then email or phone us!

Newsletter

Sign up to receive new blogs, case studies and resources – directly to your inbox.

Sign up

Discover More

Resources & Guides

Discover our product application notes, design guides, news and case studies.

Case Studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.