Why Use ‘Maximum’ Start Voltages?

You can use the voltage to adjust the speed of a motor, commonly with vibration motors this is used to vary the vibration amplitude. But just how low can the voltage be whilst ensuring the motor still operates?

We previously included the Certified Start Voltage on our datasheets. This has since been updated in the Operational Specification to the ‘Maximum Start Voltage’.

This change has confused some customers who question why we have a ‘maximum’ value, instead of a minimum.

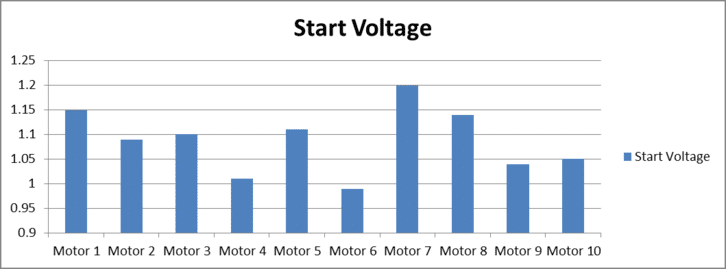

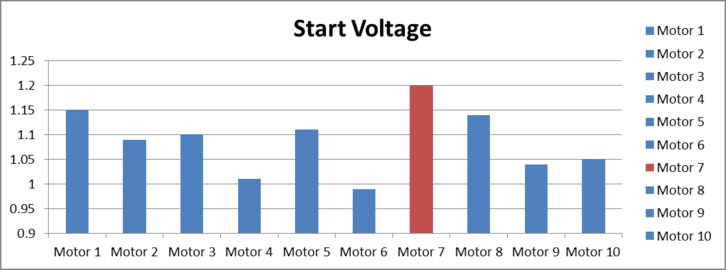

To explain, let’s walk through an example. Say we have 10 vibration motors, in turn, we connect them to a voltage source which is slowly increased from 0V, recording the voltage at which they start.

Now, mixing the motors into a bag and picking one at random – what is the lowest voltage can we absolutely guarantee it starts at? To be sure the motor will start, we must assume we have selected the motor with the highest start voltage.

Our datasheets must accurately specify hundreds of batches with thousands of motors each. It’s like an extreme version of the above scenario.

Regardless of the test sample’s size – we always base the guaranteed start voltage at the highest value (with a margin of error). Therefore, in the Operational Specification, we are specifying the maximum start voltage.

We changed from the old ‘Certified Start Voltage’ because we felt ‘Maximum Start Voltage’ highlighted the fact that motors may start at lower voltages, however, practically speaking they are the same value.

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.