“Are Your Vibration Motors Variable?”

Simple answer: Yes!

Do you mean you haven’t been reading our Application Bulletins?! This is a common question that is answered, in part, within several ABs.

Basically, the vibration strength of a vibrating motor is dependent upon the speed of the motor, amongst other characteristics. The speed of the motor will vary with the voltage applied to the motor. Therefore you can increase or decrease the vibration strength by increasing or decreasing the voltage.

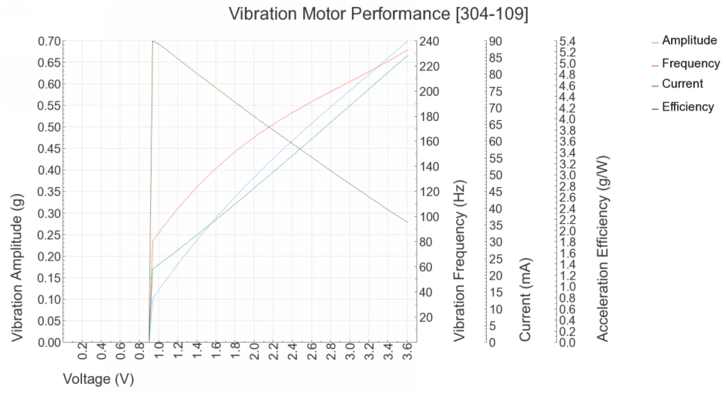

Our datasheets include a Typical Performance Characteristics graph, which is also visible on product web pages. We can easily see that as the voltage increases it is complemented by an increase in vibration amplitude. You will notice that the frequency increases (because it is a direct relation to motor speed) as does the current (it takes more energy to move things faster!):

So assuming you may want to adjust the vibration strength, but would like to power it with a constant voltage source, like a battery for example, how can you change the voltage to the motor? After all, varying vibration strengths are key to creating great haptic feedback and vibration alerting signals.

There are a couple of ways, ranging from very easy to quite complex. Here are two to get you started:

- Potential Divider and the Potentiometer/Variable Resistor

Dead simple. Place a variable resistor in series with the vibration motor. As the resistance is increased, there is a greater voltage drop across the resistor and therefore the voltage at the motor is reduced. Conversely, when the resistance is at zero, the full voltage of the supply is applied to the motor.

You can improve the performance by selecting the right value of maximum resistance for the variable resistor. Check out the Potential Divider section in AB-011: Electrical Techniques for Using Different Power Sources, and follow the calculation for \(R_{max}\).

These are also available with large knobs for user control, good for prototyping and adding customisation.

- Use PWM (Pulse Width Modulation) Signalling

This method is a bit more difficult to implement, but the theory behind it isn’t too complicated and it is the basis of creating great haptic feedback. Explaining PWM is a larger subject than this blog post, but thankfully we’ve already covered it in detail here:

AB-012: Driving Vibration Motors with Pulse Width Modulation (PWM)

It’s really that simple, you can use either of the above methods to vary the vibration strength of your vibrating motors. There are only a couple of? other points to keep in mind as you vary the voltage applied to the motor:

- Maximum Operating Voltage – this figure is found on the motor’s datasheet, do not go above it or you will dramatically reduce the lifetime or permanently damage the motor!

- Certified Start Voltage – also found on the datasheet, your motor will typically start to turn below this level but it is not guaranteed

- Brushless vibration motors – cannot use PWM signals! They often have an internal drive chip which requires a constant voltage, always check the datasheet

Pretty easy huh? If you disagree, you can always contact us for more advice!

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Newsletter

Sign up to receive new blogs, case studies and resources – directly to your inbox.

Sign up

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.