Using DC motors for Energy Harvest or LRAs for Vibration Detection

Here we’ll take a look at using our products in ‘reverse’.

It’s a fairly infrequent enquiry we receive where a customer is looking to use our motors or LRAs as the input to the circuit, but still, one we see from time to time. The two most common are turning our DC motors /gearmotors /vibration motors to produce a current (like a generator) and using linear resonant actuators as vibration detectors.

In principle, they both work. However practically speaking there are some limitations.

DC Motors as Generators

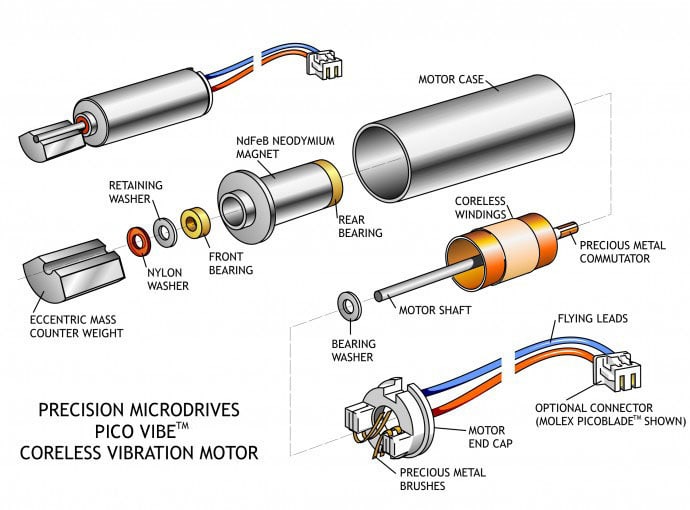

The most popular example is using one of our tiny DC motors in a modern windmill model, sometimes to demonstrate ‘green’ technology. Motors can work as generators, by turning the axle the metal windings move through the magnetic field thereby producing a current which is picked up from the commutator on the metal brushes. This is essentially the motor’s normal operation in reverse.

For DC motors (or vibration motors with the mass removed) the problem is achieving enough speed on the input. Consider our slowest DC motor, the 132-100, which has a Minimum Rated Speed of 1,800 RPM. That’s equivalent to 30 turns a second, which would be extremely difficult to achieve manually. Turning the 104-001 at its 28,000 RPM would equal 466 times a second! Due to the gearing mechanism in our DC gearmotors, you do not need to turn them as quickly, however, they are much harder to turn and require more torque.

This is where gearing can help, where lower speeds on the output shaft create a much higher speed on the motor’s shaft. However, with gearing a much higher level of torque is required – similar to riding a bicycle in high gears.

LRAs for Vibration Detection

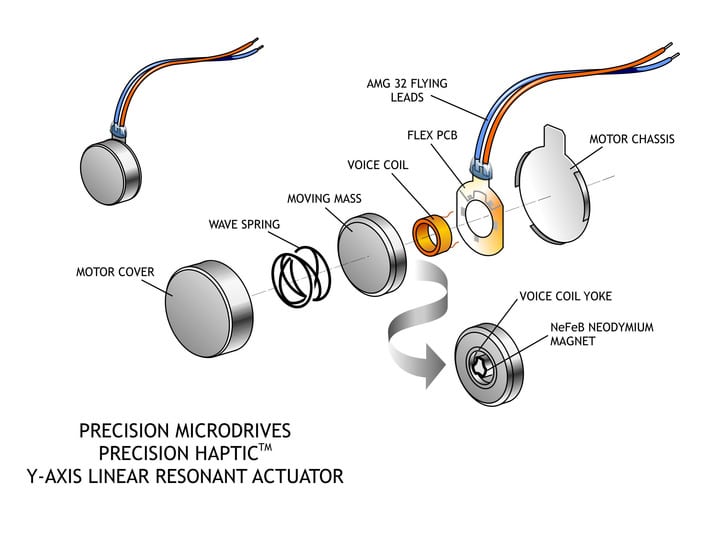

Quite a clever idea, the theory here is that vibrations would cause the LRA to displace, and the movement of the internal magnetic mass would produce a current through the voice coils. This electrical current could then be used either as a power source (as with the energy harvest idea above) or as a sensor input.

For those who have read our Application Bulletin on how linear resonant actuators work, they will know that they only vibrate at a specific resonant frequency (C10-100 175 Hz, C13-000 205 Hz). Therefore, to act as an input the vibrations exciting the LRA must be at that frequency or a harmonic. This would dramatically reduce the number of real-world applications.

Using it as a power source also has the same problem as DC motors – they are designed to be very efficient so the output would be very small. And although to use it as an impulse sensor may work, it is much more reliable to use an accelerometer.

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.