Reducing Audible Noise in Vibration Motors

DC motors don’t just produce electrical noise, they can also create audible noise. The perceived level of noise is extremely dependant upon the motor’s environment. For example, in an anechoic chamber, the sound of a motor running (or any noise at all) would appear very loud, but in our office, we wouldn’t notice due to our ears adjusting to the ambient level.

For normal DC motors and gearmotors, the sound is likely to be a high pitched ‘whir’ as the motors rotate. However, some users will be familiar with a vibration motor that appears to ‘rattle’. It’s a common complaint on mobile phone and tablet forums, although of course, it can happen to any product using a vibration motor. It may be present right from the start, gradually appear over time, or sometimes after a specific incident.

In some instances, the motor has some sort of fault and is generating the noise internally, but the most common issue arises due to the motor’s mounting. The rattling comes from the motor being allowed to move against the surface it is mounted to.

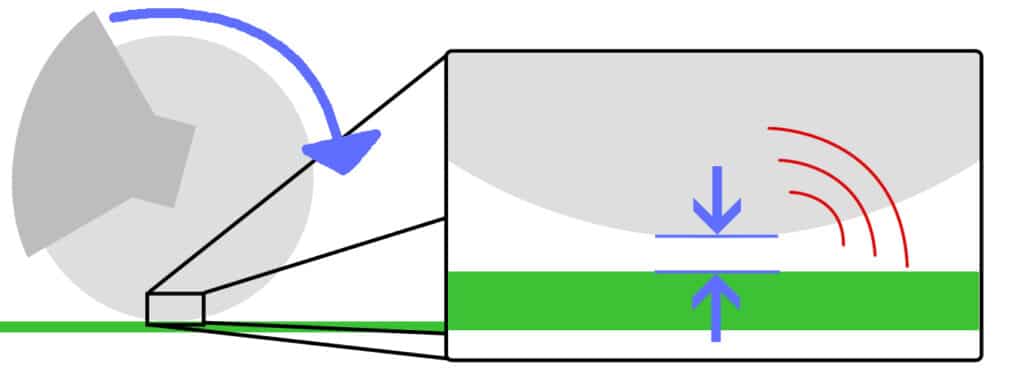

As outlined in our Application Bulletins and recent blog post on how vibrations are transferred, vibrations are a small displacement being repeated at a high frequency. The displacement is caused by the unbalanced force produced by the motor’s eccentric rotating mass. When attached (securely) to another object, like a PCB, the motor’s force is transferred across the entire system as the whole PCB starts to displace. It is for this reason that the target mass plays an important role in the resulting vibration strength, a heavier mass will require more force to move it.

Now, if there is any movement between the motor and the mounting surface it is being attached to then it will generate a noise every time it ‘hits’ the surface. It can also happen between two surfaces, such as between the PCB (which holds the vibration motor) and the outer casing.

A great example of this is comparing a mobile phone in your hand and on a table. The vibration motor is securely mounted to the phone internally, ensuring when the motor creates a force the entire phone displaces. When held, the phone creates no (or very little) noise because your fingers are soft and help absorb the displacement of the phone. However, when placed on a hard surface like a table, the phone hits the surface causing a noise. Repeat with high frequency and the result is an audible rattle.

It’s also worth noting that if using a leaded vibration motor the leads are also subject to vibration. These too can hit off surfaces and the PCB to produce audible noise.

Therefore if you are experiencing noise with your design, look for areas where there may be an opportunity for movement. The most common can be:

- Between motor and clip (if used)

- Between motor/clip and PCB or bulkhead

- Between PCB and casing

- Between connection leads and any surfaces

- Other components and surfaces that are subject to the vibration

A rattling product is not a sign of quality, so it’s an important consideration. Especially if you are looking at high-end haptic feedback. It’s also worth noting that the resulting vibration strength is also reduced as the force of the motor is not fully transferred.

For help, we have a series of Application Bulletins dedicated to mounting techniques. You can find best practices here:

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.