Tips for Powering Motors with Batteries

Many of our customers intend to use our motors with battery power supplies, which can range from the most simple of designs to complex handheld devices where the battery powers a multitude of electronics.

Here we’ll look at some of the common questions we see from battery users and highlight some of the potential pitfalls that need to be considered. Most of the article applies to all DC motors, including our gear motors and vibration motors, and we will point out any key differences. Note that help driving brushless motors and driving LRAs is better found in our Application Bulletins.

What do I need?

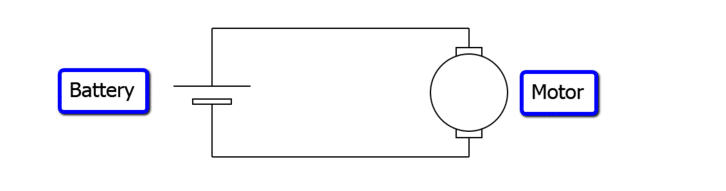

Other than the battery and the motor? Nothing.

Well, that may be a bit simplistic – you dramatically reduce your flexibility and options with so few components. However, there are many applications where the motor just needs to run in one direction at one speed and can be switched on / off by disconnecting the power:

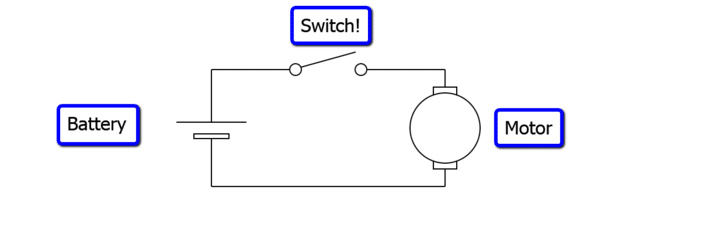

Don’t want to continually plug/unplug the battery? Try a simple switch:

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

We could look at even more complicated circuits and how they interact with the motor, but this article is focusing on using batteries as a power source. So to keep it simple we’ll use the circuit above.

How Long Will It Last?

To calculate how long a battery will last, we need two figures; the battery’s capacity and how much current will be drawn by the motor.

Batteries measure their capacity in milliamp hours, mAh. This states how many hours the battery can supply 1 mA of current, or how many mA of current it can supply for one hour.

The current draw depends on the motor, for this, we can refer to the datasheets found on the product pages. The Typical Performance Characteristics graph shows how the current varies with the input voltage (vibration motors) or with the torque load (DC and gearmotors, at rated voltage).

Then:

$$Running \: Time \: (h) = \frac{Battery \: Capacity \: (mAh)}{Operating \: Current \: (mA)}$$

This provides us with a good start, but in reality, there are several other factors that affect the operational lifetime.

Common Pitfalls

Battery Voltage

Not all batteries are created equal, make sure the voltage is at an appropriate level. For example, while a 3V motor will likely run from a 1.5V AA battery but you will get better performance connecting two AA batteries in series to create a 3V supply. Conversely, if the motor is rated at 1.5V using a 3V battery runs the risk of immediate damage to the motor (as would anything above the Maximum Operating Voltage).

The reduced voltage causes motors to turn slower. This reduces the torque handling capabilities for DC and gearmotors, whilst causing vibration motors to vibrate less.

Also, some battery designs have different voltages – even though classed as, for example, AA. Rechargeable batteries are the worst offenders for this, with the most popular types offering 1.2V.

Battery Capacity

The value of mAh is measured under very specific test conditions and is not representative of all scenarios.

In real applications, whilst the battery may perform to its rating with low and intermittent current draws, it will discharge much quicker with higher current draws. A battery with a 1600 mAh rating will provide 1 mA for close to 1600 hours, however, it will not provide 1.6A for a full hour.

Consider adding a second battery in parallel, this will keep the supply voltage the same but increase the capacity. Laptop batteries commonly use 4 cells in series to increase the voltage, and two parallel sets of the 4 series cells to increase the capacity.

Battery Voltage Shift

As batteries discharge, their voltage reduces. This effect will be more noticeable for certain types of batteries and is generally not a huge factor, but if your application is designed close to the limits it may cause failure.

Take particular note of the difference between the Typical Start Voltage (when the motor typically starts) and the Certified Start Voltage (where it is guaranteed). For DC and gearmotors the stall torque will reduce.

If you’re concerned about this, use a battery above the level you require (e.g. a 3.6V battery) and a voltage regulator set for your desired constant voltage (e.g. 3YV).

Start Current

Motors draw more current when they start (to overcome the inertia of the mass or friction in gears) than during normal operation, therefore they will reduce the battery life more than normal operation.

The datasheets include the value Maximum Start Current, but the time taken for the current draw to reduce to normal operation varies between each motor. This makes calculating the exact running time very difficult.

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.