Surface Mount (SMD / SMT) Vibration Pager Motors

One of the biggest benefits of using PCB mounted vibration motors, is that assembling the motors into an application is often at least partially automated. They are also great for retro-adding haptic feedback or vibration alerting to products where modification of the enclosure (which is the only other place that you could mount a motor) isn’t practical or economically viable.

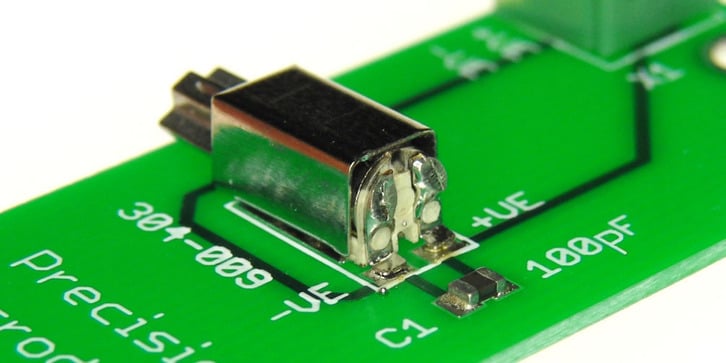

Of course, this assumes that there is enough PCB space to accommodate the motor foot-print, which is where our SMD reflow vibrator motors can be a good choice, with a minimal single-sided footprint. Generally, SMD vibration motors have two electrical connections on the back of the motor, and a rectangular over-casing with a large centre ‘pad’ that anchors the motor to the PCB.

In addition to their diminutive size, SMT pager motors are very labour efficient to assembly into an application. Motors come on reels and are designed to be suitable for pick and place machines, prior to reflow, which means they can be assembly automatically along with the rest of the host board’s components.

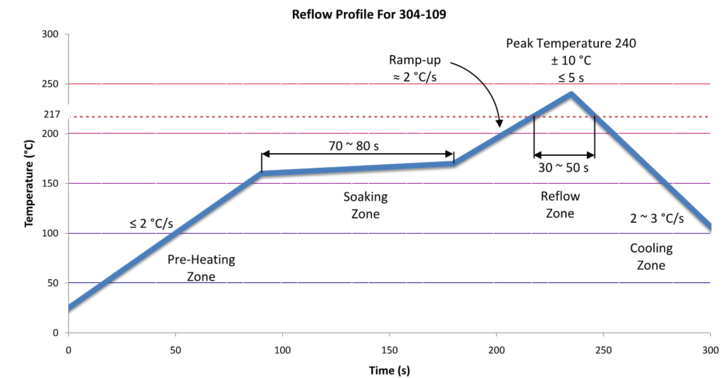

The only thing to remember from a manufacturing perspective is to adhere to the reflow temperature guide (below), and that the motors must not be exposed to any liquids (e.g. flux washes or conformal coatings).

A small extra benefit comes in the form of better EMC suppression performance. Like the through-hole vibration motors with thru-hole electrical pins, one can place an EMC suppression filter very close to the commutator circuit. A small ceramic capacitor will do the job, but it’s also possible to use a more exotic X2Y filter if necessary. Take a look at our application note about vibration motor EMI / EMC suppression to learn more about this.

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.