Example Haptic Feedback Applications

Looking for our Haptics range? View our main Haptics hub here.

Below are some example applications that could benefit from the addition of haptic feedback. The specific products suggested are representative of the overall category, if you want any advice on your specific application please don’t hesitate to get in touch using our contact details. You can continue to read about haptic feedback using the chapter navigation and the bottom of the page.

Portable Devices – TETRA Radios

In a similar way that mobile phones and pagers moved beyond the simple ringing alerts, now a variety of handheld and body-worn portable devices are benefiting from vibration features. With the advancement in controllers and bandwidth, small portable devices are now required to process high volumes of complex data but still rely on visual or basic audible outputs.

There are other catalysts for including vibration technology too. Some require their product to be more discreet, others need to be noticeable in loud environments, and many are looking to innovate with haptic feedback to effectively convey more information to their users.

One of the most difficult design constraints for portable devices is balancing the size and weight of the unit to fit all the necessary components. Consider the TETRA radio example above, in addition to having a rugged external construction the unit houses the antenna, screen, keypad, electronics, and a large battery. However to maintain its portability the unit must be able to fit in the user’s hand and as light as possible.

Adding tactile feedback is much easier than first anticipated, many drivers will use the data standards as the existing controller (I2C / CMOS logic and PWM) and have PCB footprints under 1.5 x 1.5 mm. We have a wide range of high-performance vibration motors to fit different mounting techniques, including our Precision Haptic™ 308-102 that produces 5.5 G and is only 8mm in diameter.

With a new tactile feedback feature, users of the TETRA radio can benefit from discreet personal notifications and can be alerted through vibration technology. Improving your products through the addition of new features demonstrates your company has the technical expertise to stand above your competitors.

For help in positioning the vibration motor to maximise the effect of the vibration, we have a series of Application Bulletins that cover mechanical mounting. We also have a larger guide to tactile feedback for more information or contact us with any questions.

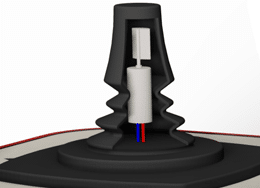

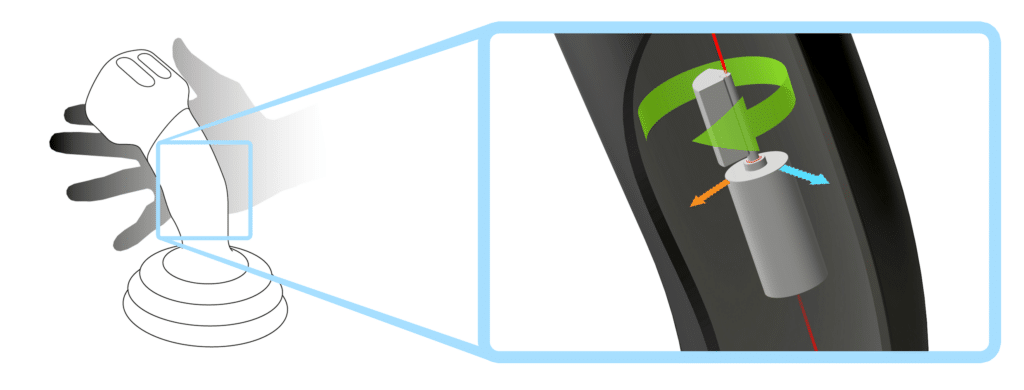

Control Stick Interfaces – Crane Controllers

Controlling large industrial equipment, particularly those that need accurate placement, can be difficult using a remote control. Part of the reason is that the equipment can be too large or complex for the operator to easily see everything they need to. Not only is positioning important but there is a range of dangers present with large machinery. A sensor can be installed for detecting overloading, proximity warnings, etc., but using LEDs or sounds can be distracting for the user.

Whether the operator is located inside the machine (e.g. construction vehicles) or remotely (e.g. crane controller example below) haptic force feedback can help convey information directly to the user through the control panel, leaving them to concentrate on the task in hand.

Early examples of vibrotactile feedback can be found in gaming controllers, historically referred to as ‘force feedback’. Joysticks, car wheels, aeroplane yokes, and gamepads all used haptics to either add to the in-game experience or convey information to the gamer.

These game controllers are based on real-life input systems for vehicles and machines. Adding a vibration motor and driver can enable some of the same benefits, except instead of making a game more fun they improve worker productivity and the aid product/worksite safety.

Many of these input components, like the joystick in the crane controller example, benefit from good mechanical isolation so the entire mass of the unit doesn’t affect the vibration strength of the motor. The advanced vibration patterns available through haptic force feedback help the crane operator understand positioning through varied vibration amplitude and frequency, similar to the audible beeps in car parking sensors. They can also serve as early warning systems through intense vibration strength.

With haptic force feedback directly into the operator’s hand, they now are able to process information whilst continuing to look at what they’re focusing on. Improving your products through the addition of new features demonstrates your company has the technical expertise to stand above your competitors.

For help in positioning the vibration motor to maximise the effect of the vibration, we have a series of Application Bulletins that cover mechanical mounting. We also have a larger guide to haptic feedback for more information or contact us with any questions.

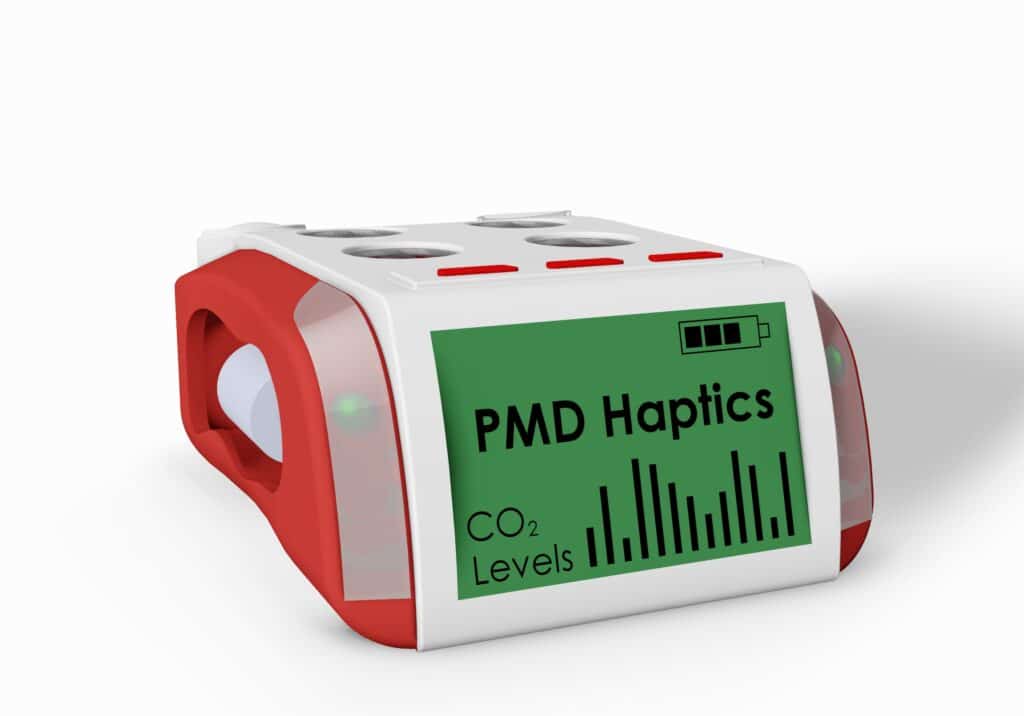

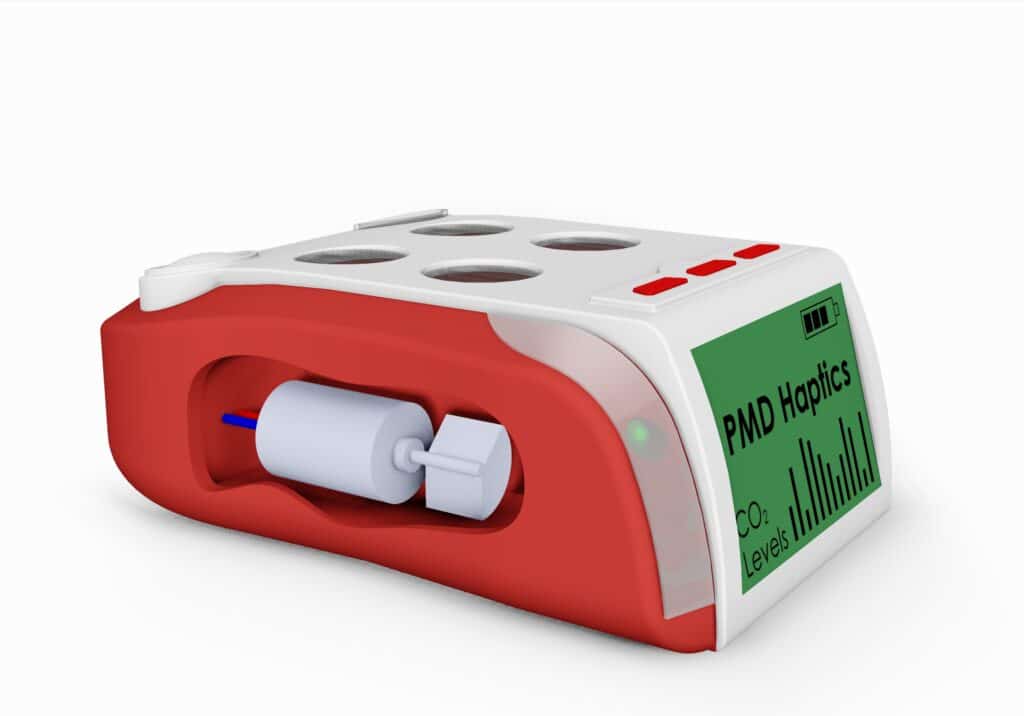

Body Worn Devices – CO2 Gas Monitor

People who work in dangerous environments often have to concentrate on a variety of important tasks, and their attention may not be always focused on reading the status/levels of their safety equipment. It is the reason they are often fitted with other audible or visual cues like speakers and LEDs.

There are situations where these alerts may not be suitable, such as loud areas or where the equipment isn’t in the line of sight. Using vibrations, haptic feedback is an innovative feature that can augment the safety equipment, making it more effective and ultimately increase the safety of the user.

Using a CO2 gas monitor as an example application, we can see that safety equipment needs very little work to add vibrotactile feedback. As the device is specifically designed for measuring aspects of its surrounding environment, in this case, levels of CO2, the input is already installed. The monitor processes this information and displays it on the screen to give the user detailed information.

In the event of high CO2 levels, the monitor may produce a beeping sound or change the colour of LEDs. A simple addition to the code of the controller can produce an additional warning signal through tactile feedback. With many haptic drivers supporting I2C or PWM signals the programming and electronics are simple.

The user can now benefit from an additional early warning system that they neither need to see or hear in noisy environments. Improving your products through the addition of new features demonstrates your company has the technical expertise to stand above your competitors.

For help in positioning the vibration motor to maximise the effect of the vibration, we have a series of Application Bulletins that cover mechanical mounting. We also have a larger guide to haptic feedback for more information or contact us.

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Handheld Devices – Barcode Scanner

Tactile feedback can be used as a great alternative to replacing annoying audible alerts. Anyone who has spent any length of time at a supermarket checkout can relate to the annoyance of the repetitive monotone beep. Similarly, with touchscreens, they are now more commonplace in white goods, but many still use sounds to notify the user it has registered the input.

This can be easily removed by using simple vibration technology to interact with the user. Electric torque wrenches, medical instruments, and barcode scanners (like the example below) are just some of the light handheld devices that can benefit from adding tactile feedback.

As barcode scanners are usually quite light and the operator doesn’t need protective clothing, the vibration strength does not need to be very strong. This opens up a wide selection of vibration motors to meet different product weights, voltage/haptic-feedback supplies, or other design constraints.

Easily mounted in the handle, a cylindrical ERM vibration motor like is perfect for creating vibrations directly into the grasp of the operator. Now when scanning codes the user will receive feedback for a successful scan, or unsuccessful, along with a variety of other notifications like low batteries, errors, etc.

When coupled with an LED the tactile feedback augments the design to make using the product much more pleasant, not just for those using the product but also for those in the vicinity. Improving your products through the addition of new features demonstrates your company has the technical expertise to stand above your competitors.

For help in positioning the vibration motor to maximise the effect of the vibration, we have a series of Application Bulletins that cover mechanical mounting. We also have a larger guide to haptic feedback for more information or contact us with any questions.

Touchscreens – CNC Control Station

One of the major benefits of touchscreen technology is the increased operating speed where other input peripherals are not suitable. At supermarket self-serve checkouts, it is simply not practical to use a mouse and keyboard. Similarly with industrial machines, like the CNC mill example below, control terminals are best replaced with a mixture of touchscreens and other control knobs/joysticks.

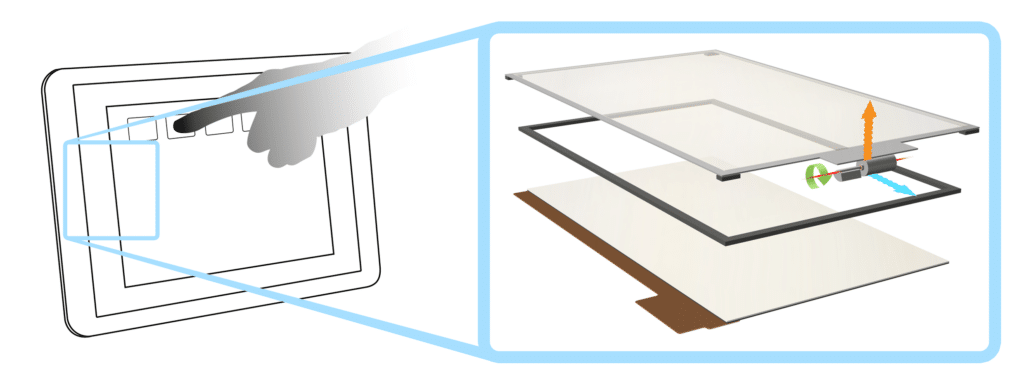

Touchscreens offer a huge range of benefits, including a compact size and the ability to quickly work with a varying graphical user interface. However their biggest drawback is the loss of tactile response for the user, they no longer feel the ‘click’ of pressing buttons. This leads to user uncertainty (“did that register?”) and ultimately frustration with the product. Adding haptic touch feedback is the most effective way to solve this.

Taptic touch feedback in touchscreens is one of the most well-known examples of the technology. With mobile phones and tablets leading the charge, the added benefits to the user now make touchscreens without haptic touch feedback seem odd.

Using advanced drive signals you can use a variety of patterns to convey information to the operator. Different effects can be used in different situations, like a ‘double-click’ sensation for a ‘long press’ to access additional menus or a strong ramp up for cancelling/starting a procedure. These patterns can be easily created or accessed through different driver chips.

Although eccentric rotating mass vibration motors can be used, the benefits of linear resonant actuators are highlighted in touchscreen applications. With very quick response times and vibrations produced in only one axis, directly towards the user, they are the perfect solution for implementing haptics. Their low profile and self-adhesive backing make them easy to mount.

The inclusion of haptic feedback demonstrates to your customers you understand how they work and you cater to their needs. For help in positioning the vibration motor to maximise the effect of the vibration, we have a series of Application Bulletins that cover mechanical mounting. We also have a larger guide to haptic feedback for more information or contact us below with any questions.

For help in positioning the vibration motor to maximise the effect of the vibration, we have a series of Application Bulletins that cover mechanical mounting. We also have a larger guide to haptic feedback for more information, or contact us with any questions.

Newsletter

Sign up to receive new blogs, case studies and resources – directly to your inbox.

Sign up

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.