Vibration Alerting for Industrial Protective Clothing

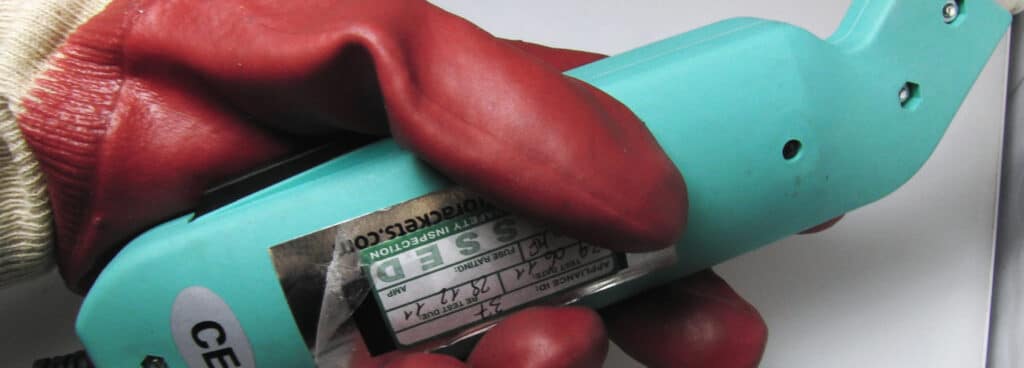

Many of the example applications we have offered for vibration alerting have centred around handheld tools and user interfaces that would be used on an industrial or construction site. The issue here is that often the operators will be wearing some form of protective clothing. For example, when working with handheld tools like a haptic electronic torque wrench the user will likely be wearing thick gloves.

To ensure the vibrations are felt through protective clothing, it’s not just a case of increasing vibration amplitude. Although this can work, you will end up sacrificing efficiency or size.

Instead of selecting a larger or faster motor to increase the vibration amplitude, consider using a slower motor. It may seem counter-intuitive given an increase in speed is complemented with an increase in vibration strength.

However, the speed also determines the vibration frequency, where:

$$ f_{vibration} = \frac{MotorSpeed(RPM)}{60}$$

The vibration frequency can play an important role because high frequencies suffer more from dampening, caused by the padding in the gloves or other clothing.

As an additional benefit, the low frequencies are less likely to be confused with the effects from Carpal Tunnel Syndrome (CTS) and other health complications that cause the tingling of nerves in the hand/wrist. Obviously, health and safety is a big concern for those working in industrial environments.

Try considering motors that produce vibration frequencies less than 200 Hz, that’s around 12,000 RPM. You can filter our vibration motors in our product catalogue.

Or alternatively, you can take a look at some of these suggested motors for adding or improving vibration alerting in industrial handheld products and control systems.

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.