Spur Versus Planetary (Epicyclic) Gear Types

Precision Microdrives offers two types of high-quality DC geared motors: spur and planetary gear trains. During the design phase, the designer must select the type of DC geared motor that is the best fit for their specific application. Due to the physical arrangement and construction of gear trains, each type has its own design criteria.

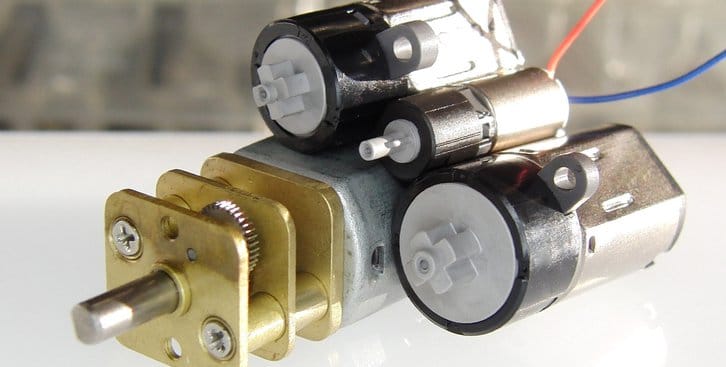

Constructed, typically, from steel or brass, a spur geared motor consists of straight-toothed gears that connect parallel shafts. This arrangement of gears provides high torque at a low speed. Depending on requirements, the designer should consider:

The size of the gears

The number of teeth on each gear – specifically the gear ratios for the output torque and speed of the shaft.

What are the differences between spur and planetary gearmotors?

Spur gearheads are usually cylindrical, in a form-factor similar to the motor they are attached to, though they can be other shapes as well. Use straight gear teeth gearboxes in low-speed applications. The gears, constructed from steel, create noise when they rotate and their teeth collide. This repeated collision can damage the teeth of the gears. You should take precautionary measures. If only one of the gear teeth is repeatedly stressed, this may lead to fracture failure. Another disadvantage is that the spur gear slips and does not apply the torque to the actuation object. From a manufacturing point of view, the spur gear motor has a lower production cost (compared to planetary gear types) as it needs fewer gears and requires a simpler manufacturing process. Precision Microdrives has a range of spur gear motors suited to your application requirements.

As a designer, you may also consider planetary geared motors. These come in a variety of power levels and sizes to fit your application needs. Planetary gear motors, usually cylindrical in form, are made of steel, brass, and plastics. It’s easy to get very low gearings in a small space using planetary gearings. They have a large amount of meshing tooth surface area. So, you can get large amounts of power transfer without worrying about stripping gears.

A planetary gear train consists of several planet gears, a sun gear and an outer gear or annulus. It also consists of a movable arm or a carrier that holds the planet gears. The carrier, along with the planet gears, rotates around the sun gear. In the gearing configuration, the outer gear or annulus rotates with the planet gears. In the planetary gear system, the axes of the gears are usually parallel to each other and are concentric. Disadvantages include high bearing load, inaccessibility, and design complexity. However, the advantages of planetary gears over parallel axis gears are compact size, higher efficiency, and low noise level. The gear train itself has a higher level of stiffness, along with its uniform mass distribution, making it highly stable. In planetary gear systems, the load is shared by two or more teeth.

Precision Microdrives is committed to providing high-quality planetary geared motors offering low noise, strong torque, long lifespan, and high efficiency.

Example Application 1:

Question: What type of DC gearmotor should you use for an application that moves an item between two states, e.g. a locked/unlocked latch, and why?

Answer: Spur DC gearmotors are very simple and low in noise. As the advantages of a planetary gear head (see below) are not essential, a higher efficiency spur geared motor can be selected.

Example Application 2:

Question: What type of DC gearmotor should you use for a kitchen appliance or a piece of medical equipment?

Answer: This can be device specific, it is likely the actuation for a kitchen appliance or a piece of medical equipment may have drive operation and that space is restricted. This would require a DC gearmotor with higher load capacity and smaller size. To meet this design requirement, a planetary gear system will be your best choice.

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.