Mounting Vibration Motors to Flexible PCB

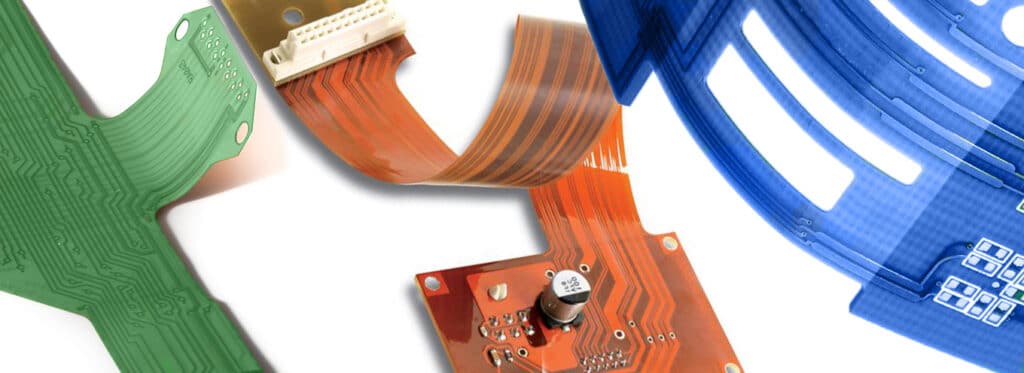

There are several design considerations when mounting vibration motors to flexible PCB, also known as FPCB, or just “flex”.

For mounting an SMD motor (with solder) to flex, you will require some kind of backing material around the motor to stabilise the joint (perhaps a circuit board base material such as 0.8mm FR4). Alternatively, you may be able to order your flex PCB with rigid sections.

If you choose to mount without solder, perhaps because you’ve chosen a spring-mounted motor such as the 310-105 then you need to ensure that there is sufficient pressure between the motor contacts and the PCB.

Also, if you choose an ERM motor with an exposed rotating mass such as the 304-008, then you’ll need to ensure your design prevents the mass from making contact with other components or the casing as the PCB flexes. This is because impeding the mass causes current spikes, reduces performance, and creates audible noise.

However you choose to mount the motor, there are a few additional design considerations:

- If you mount to flex PCB you may damp the vibration

- Depending on the mounting, there may be audible noise generated as the motor vibrates against the flex PCB

If you decide against using flex, we have application bulletins that will help you mount vibration motors to rigid PCB or bulkheads.

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Newsletter

Sign up to receive new blogs, case studies and resources – directly to your inbox.

Sign up

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.