MTTF published results for vibration motors 307-103 and 307-104

Introduction

At PMD we not only manufacture high-quality miniature motors and mechanisms, but we also design and make our own testing equipment. This means that we have a wide range of proprietary dynamometers, and environmental and longevity testing equipment so that we can have confidence in the reliability of our parts. One of the instruments is a dedicated MTTF (Mean Time to Failure) testing machine, designed for vibration motors.

Our vibration motor longevity testing machine can test 48 motors at the same time, which is enough to provide a statistically reliable sample for measuring motor lifetime. Our vibration motor MTTF machines are run at 720-hour testing intervals. However, often this is not long enough to produce sufficient failures, and the more failures we can produce, the more confident our MTTF figure will be. So often a second interval of testing is needed due to the low quantity of failed motors in the first interval. Typically completing an MTTF normally takes over two months, except in the case of brushless motors were trying to get a statistically significant number of failures within a ‘reasonable’ amount of time, is a real challenge.

Motors in our MTTF testing machine are typically run with an operating cycle of 2s On / 2s Off.

MTTF for vibration motors is more broadly explained in our Application Note 19, in addition to the wear mechanisms that are typically observed.

MTTF tests on 307-103 and 307-104

So for the purposes of this blog post, we have currently finished an MTTF test for two more of our vibration motors. Both the 307-103 and 307-104 are exactly the same motor, however, the 307-103 comes with a plastic encapsulation. They are coreless brushed motors with a vibration amplitude of 7G. They are usually included in medium size devices (>100 grams) to provide a crisp and strong haptic feedback.

We are excited to publish the results of the latest MTTF test conducted on these motors. The results show these two motors to have a high longevity, even more, interesting considering that we are talking about brushed motors. As a rule of thumb, most of our more demanding customers usually ask the motor to last for 1 million haptic cycles. So these tests confidently demonstrate that these two motors meet these kinds of requirements.

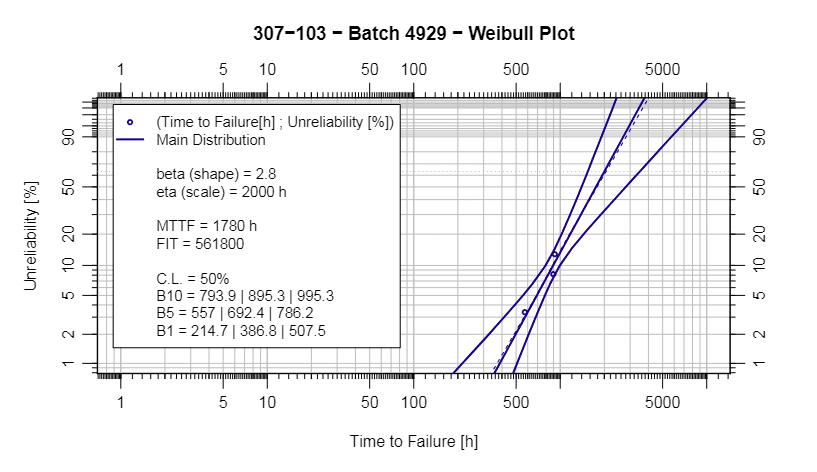

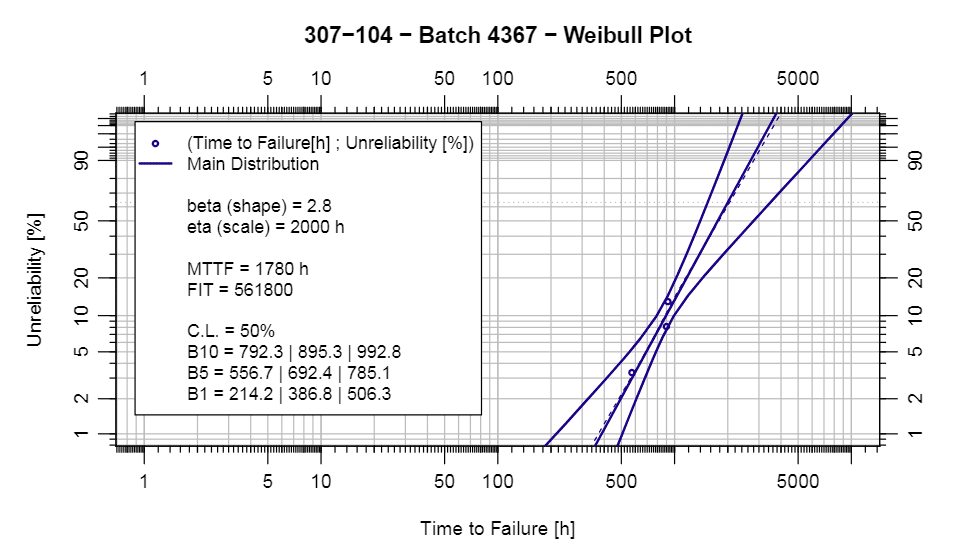

The output of these tests is presented in a Weibull plot. The graph shows how many failures you could expect in terms of a percentage (unreliability %) from a lot of parts, at various part lifetimes. Since it’s a statistical measurement, there is a lower and upper bound, which represents the left and right lines respectively. The line in the middle is the best fit.

In addition, we publish an MTTF figure which for these motors is ~1780 hours mean time to failure with an operating cycle of 2s On / 2s Off.

Summary

There is more information about what MTTF ‘actually means’ in our Application Note 19. However, in summary, both the 307-103 and 307-104 motors can endure a large number of haptic events or vibration alerts, before the inevitable increase in the likelihood of failure.

Our MTTF testing programme continues, and you can expect to see more of our parts featuring MTTF data over the coming months!

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Newsletter

Sign up to receive new blogs, case studies and resources – directly to your inbox.

Sign up

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.