A Guide to Reading PMD Motor Datasheets

How frustrating is it when you can’t find the information you need? It can even be worse when everything is in front of you, but somehow makes no sense – it may as well be in a foreign language. That sinking feeling that you’re wasting time, and everyone has their own solution too:

“I’ll make another cup of coffee!”

“I’ll just come back to it later”

or, my favourite –

“I know, I’ll read it slower! Concentrate…”

Sometimes you don’t understand what the data means, but often the problem is that the information in front of you lacks context. I understand the values, but do they affect my design? What information is relevant to me?

Help is at hand!

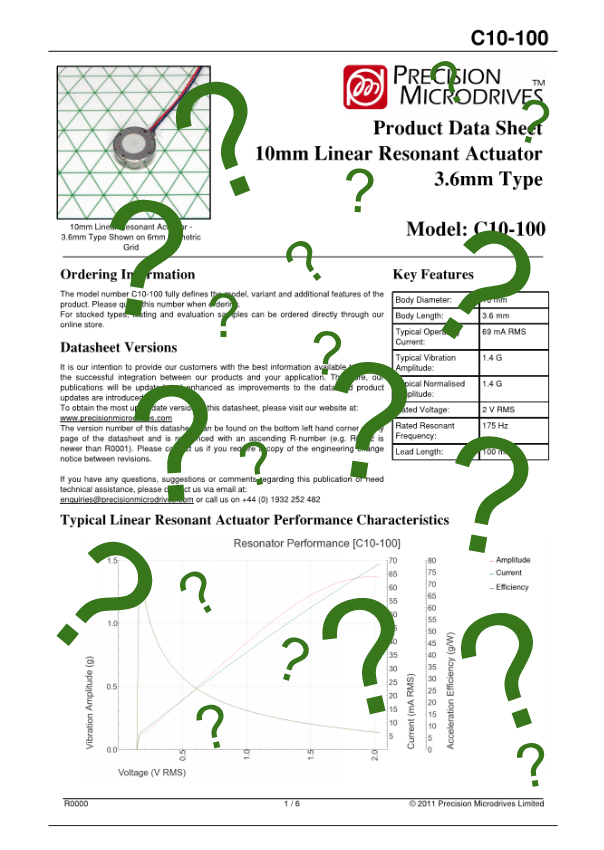

For each of our devices, we produce datasheets and product web pages packed full of specifications and results from our testing procedures. We even summarise key features and performance graphs on the front page for easy access and quick filtering. But wait, there’s more…

We have just released a help-guide to aid you through our datasheets. It can help you save time in understanding the data, and can be used as a quick reference if you are having troubles with a particular section.

So please take a look, you can click here (content has since been depreciated!), it’s a great resource designed to save you time and frustration. Part of our job at Precision Microdrives is to help you do your job as efficiently as possible, and of course, if there’s anything you still have questions about you can drop us a line at [email protected].

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Newsletter

Sign up to receive new blogs, case studies and resources – directly to your inbox.

Sign up

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.