Dynamic Dynamometers Upgraded to Support Advanced Application Torque Profiling

Here at Precision Microdrives, our motto is ‘On Time and To Spec’. To ensure we can fulfil this commitment to our customers we test each motor batch and we’re always looking to improve our test procedures (did you know we are ISO 9001 certified?).

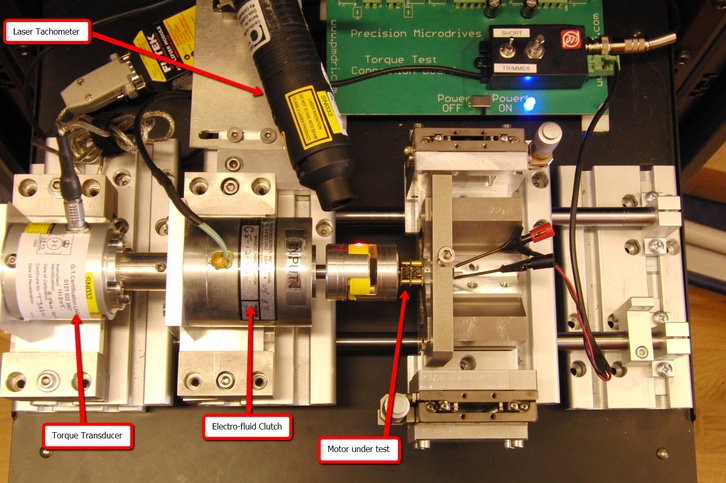

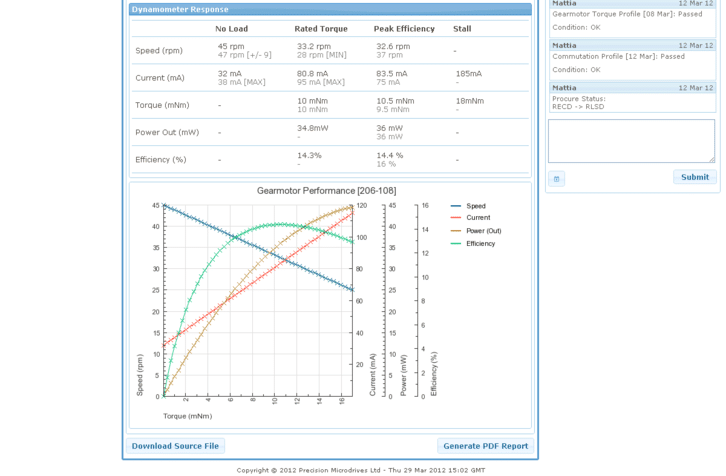

One of the tests we subject our DC gear motors to is our Gearmotor Torque Profile test. This uses a dynamic dynamometer to analyse how the motor performs with varying torque at its rated voltage. We have recently upgraded our dynamometer to ensure we gather a wide range of data from the motors we test.

This new improvement allows us to load the motor with application torque profiles. While previously we could fully test our gear motors with a sweep technique, which we still predominantly use, we can now simulate an application by electronically varying the dynamic torque over time… very useful for seeing how a gear motor will perform through its application lifetime.

We can even perform this type of test on our miniature 6mm gearmotors. We recently released the 206-108 which was one of the first to undertake the new test for a lock application. Although the 206-108 is small in size, you can see from the results below that it packs a punch with up to 20mNm of useful torque at 20 rpm through a 700:1 planetary gearbox.

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Newsletter

Sign up to receive new blogs, case studies and resources – directly to your inbox.

Sign up

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.