Lifetime of Vibration Motors

We’re often asked about how long our vibration motors last. The industry standard is 100k cycles of 1 second on followed by 1 second off. The more mathematical of you will note that this is a cumulative on-time of 27 hours. Evermore customers are asking for FIT and MTBF information for these motors and no-one has ever done statistical analysis.

We’re leading the front on this with the introduction of a parallel longevity test which will come online in the next month, whereupon we’ll be collecting and analysing statistical lifetime information for certain parts. In the meantime, this post is about a longevity test that surpassed all our expectations.

Testing longevity takes a long time, obviously. In fact, this little experiment started back in August 2011! When performing the test on several different motors (including types and batches) we came across a very unexpected result. One of our motors just didn’t stop, and we were curious to see how long it would go on for, so we let it run…

A couple of weeks back, it finally gave up, and we thought it would be interesting to share our results. Readers should note that this is definitely not typical performance, and our motors should not be expected to achieve the same results but it is interesting none the less.

The Motor

Loyal followers will remember our product release of the 304-108 (since removed!), a 4mm spring-mounted vibration motor. The key feature for the purposes of this article is that the Pico Vibe™ vibrating motor is a brushed DC motor. The main cause of failure for these types of motor is the degradation of the internal precious metal brushes. The mechanical wear starts to fill the gaps in the commutator as the material is mechanically rubbed off from the brushes through attrition. Eventually, the commutator gaps fill and short, or brush fatigue causes them to break altogether. Both situations result in an eventual permanent failure to start/run.

The Setup

The motor was mounted on one of our vibration test sleds and powered at its rated voltage in repeated bursts – 2 seconds on, then 2 seconds off.

We measured both the operating current and the vibration amplitude of the motor, once every 20 seconds. The data and timestamps were all stored automatically on our engineering test database.

The Results

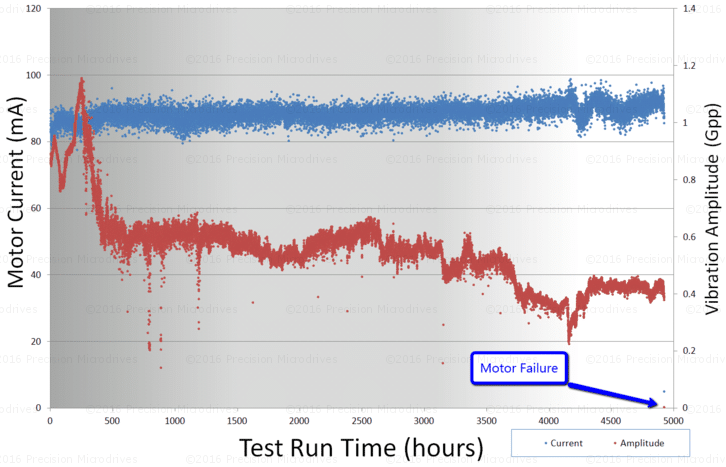

The graph below shows our results:

There’s a couple of interesting points. First is that the motor finally failed after close to 5000 hours, which is around 7 months. Of course, the motor spent half of this time switched off, but nearly 2500 hours of run time is still exceptional.

For many applications, the motor will actually spend most of its time switched off. This is particularly true for vibration alerting and haptic feedback applications where the users will not be working, or even awake, for the whole day. This means for some applications the vibration motor could outlast the product’s lifecycle.

We can also see how the motor’s vibration performance degrades over its lifetime. After it’s initial run-in phase, the motor performs reliably until it enters the latter stages of its life where there is another noticeable dip in performance before finally burning out.

Finally, we can see the motor enters the ‘burn out’ phase around the 3700-hour mark. The vibration strength declines and becomes a bit more erratic – although still at a level 10 times the sensitivity of human touch (0.04G by the way).

Another interesting note is the slight linear increase in Motor Current throughout the motor’s lifetime. It’s also fairly constant, with the exception of a blip around 4400 hours (likely due to brush plating material being worn through and metallic dust from brushes/commutator in the motor case). It’s worth remembering that if you intend to use the motors to the very end of their lifecycle, that your current control cannot be too strict or it may decrease performance in later life.

We’re going to follow-up on this with more information about motor lifetime testing, but for now, if you have any questions about the expected lifetime of specific motors, please feel free to contact us.

Get in touch

Speak to a member of our team.

Motor catalogue

Looking for our products?

Reliable, cost-effective miniature mechanisms and motors that meet your application demands.

Newsletter

Sign up to receive new blogs, case studies and resources – directly to your inbox.

Sign up

Discover more

Resources and guides

Discover our product application notes, design guides, news and case studies.

Case studies

Explore our collection of case studies, examples of our products in a range of applications.

Precision Microdrives

Whether you need a motor component, or a fully validated and tested complex mechanism – we’re here to help. Find out more about our company.