Precision Microdrives Motor mechanisms

Custom motor assemblies designed and manufactured in house

Expedite your motor and mechanism development

Trust Precision Microdrives to manage your development and manufacturing risks

Precision Microdrives offers a full turnkey service, to prepare design inputs, develop a manufacturable solution and mass produce

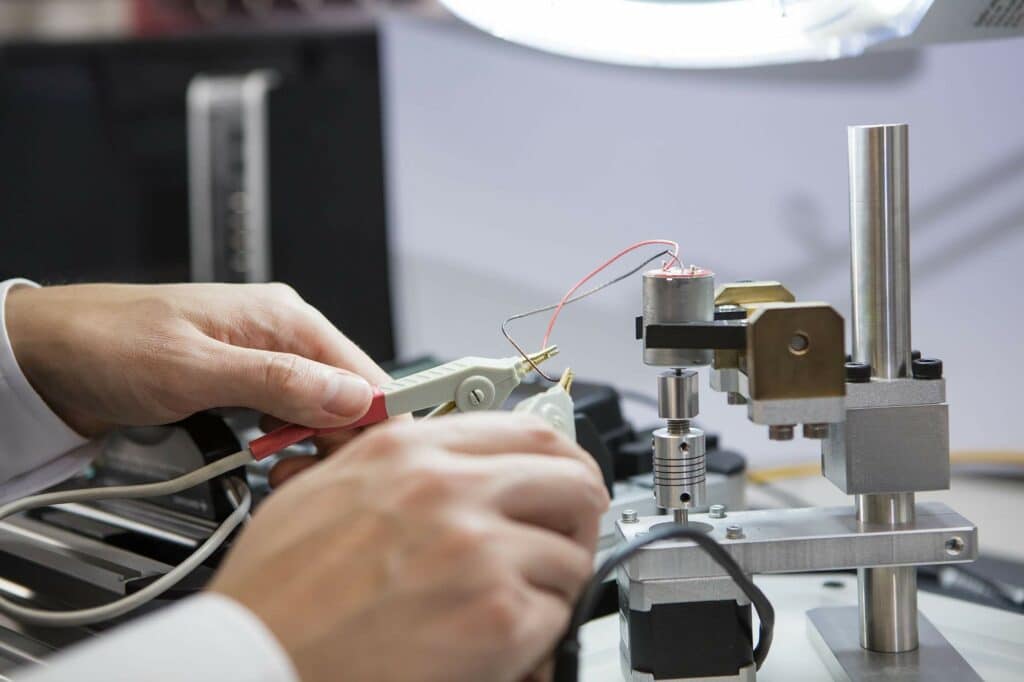

Motor mechanisms are easy enough to prototype. But with many moving parts, they soon become a real challenge to mass-produce both cost-effectively and to a consistently high-quality standard. Precision Microdrives is a domain expert in this niche discipline.

Speak to an engineer

We offer a full turnkey ODM service

Preparing design inputs, developing a manufacturable solution, and on-ramping into mass production. Our business is optimised for this very process.

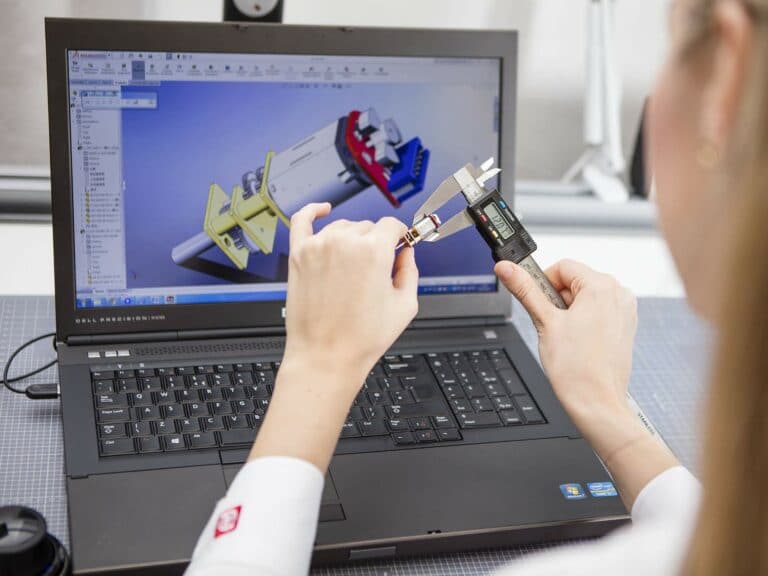

OUR ENGINEERS IN EUROPE:

Design for your application

Our design engineers in Europe are in the right place, timezone, and have the right language skills to work very closely with your engineering team. Together we’ll develop accurate specifications and design inputs.

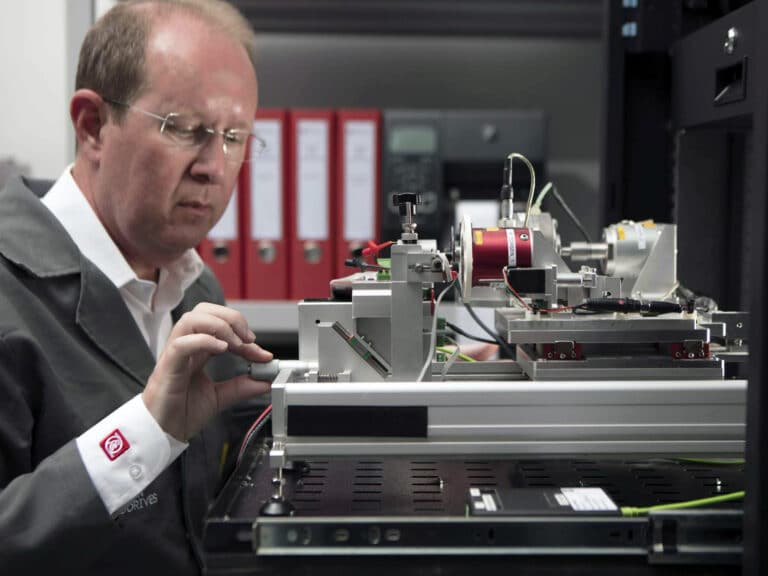

OUR PRODUCT ENGINEERS IN HONG KONG:

Develop and test

Our product engineering team in Hong Kong have the language skills, supplier relationships and necessary design-for-manufacture experience to develop complex assemblies. They are experts at sourcing individual sub-components from a lower cost Asian supplier ecosystem. They’ll work with our design engineers to implement a solution that we’re all proud of.

OUR IN-HOUSE MANUFACTURING LINES:

Produce and manufacture

Our in-house manufacturing lines are co-located with our Hong Kong engineering team. This is very unusual for Asia, but it makes manufacturing optimisations, process, quality controls, and ongoing production management significantly easier. This is where your mechanism will be built, tested and shipped from.

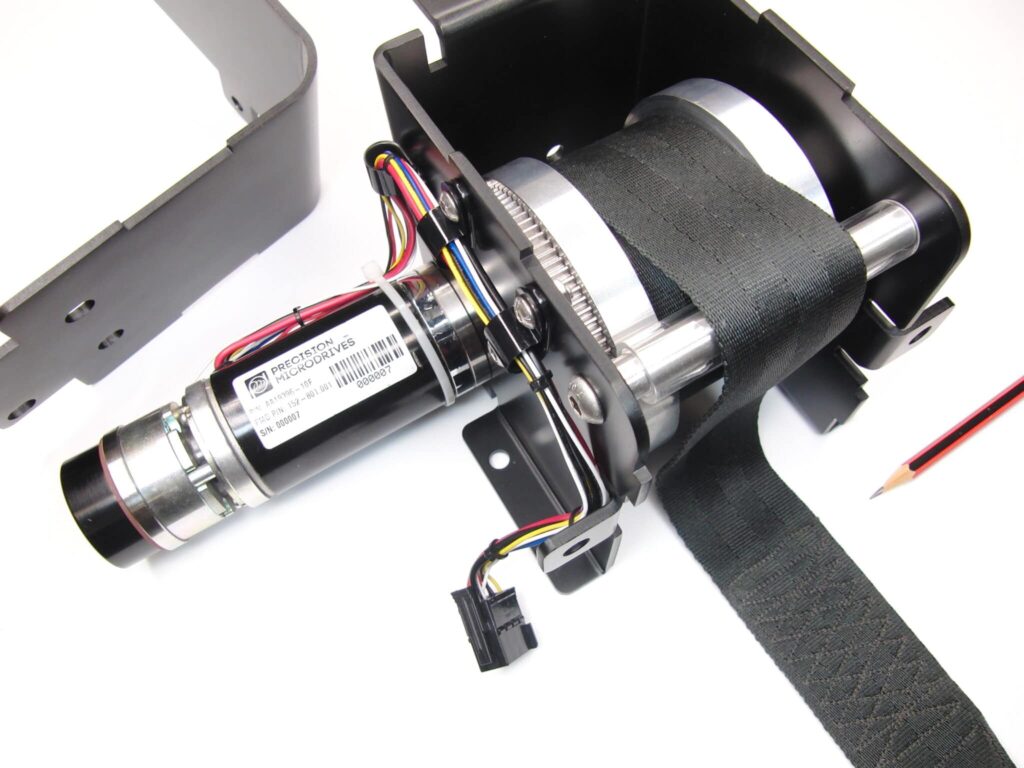

MECHANISM CASE STUDY

Medical diagnostics instrument

A robust and low-voltage healthcare mechanism manufactured in-house

- Hospital lift application, manufactured in the USA.

- The patient lift was required to lift 350 kgs from an overhead gantry.

- Mod 1 gear train, coupling 52mm high torque coreless motor to the lifting drum.

- Fitted with an encoder for motion control, and a fail-safe electro-magnetic brake.

- Introduced as part of a product lifecycle update, which lead to increased sales by 36%.

- Our customer’s engineering resources were freed up to work on new and more valuable future developments.

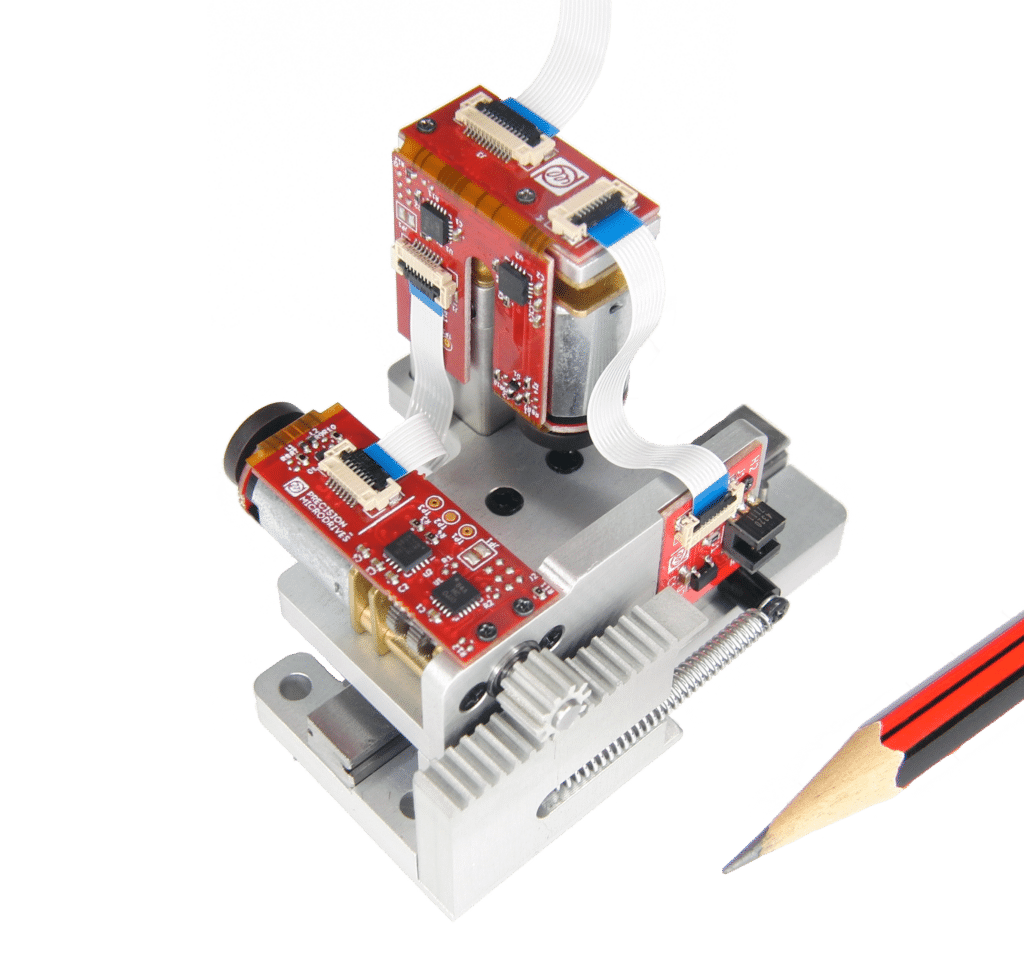

MECHANISM CASE STUDY

Heavy duty mechanism for hospital patient lift

A robust and low-voltage healthcare mechanism manufactured in-house

- Update of a bench-top medical diagnostics instrument, manufactured in Germany.

- The mechanism cost had to halve, whilst maintaining the same accuracy.

- X axis positional accuracy to 25 μm (½ of a human hair), and Z axis to 12.5μm (¼ of a human hair).

- We designed from our library of components, including integrated encoders, home sensors, and custom motion controllers.

- Our assembly interfaced mechanically directly into the customer’s instrument chassis.

- Our motion controllers interfaced directly to the instrument’s host processor, over SPI.

Specialised engineering services and capabilities

YOUR DC GEAR MOTOR ENGINEERING PARTNER

Why Precision Microdrives?

Trusted motors and mechanisms

Getting the core of your application correct, first time

Motors and mechanisms are likely one of the most expensive lines on your BOM and also the least likely to be noticed by your customers. Until they fail…

So, choose an engineering partner that has extensive domain expertise in mitigating the technical risks of these complex products.

Rely on a manufacturing partner with a presence on the ground, robust quality control processes, and a familiar approach to maximising your value-add.

Priced to deliver the best value

We engineer our products to be optimised for your application and delivered at a best value cost.

We don’t engineer our solutions to the highest possible standards, or the lowest possible costs.

That’s not the only way we help your profitability either.

Add a very technically experienced, cost effective addition to your development team. We will free up your internal resource to focus on more valuable R&D work, which will expedite your development cycles.

Working with Precision Microdrives

Manufacturable design

- We design solutions that are manufacturable and reliable.

- Tested and validated for longevity, performance and environment.

Technical expertise

- Absolute domain experts in motors and mechanisms.

- If we can help by sharing our expertise and experience, we will.

Robust quality controls

- Quality teams in Asia to control upstream component suppliers.

- QC methods developed specifically for motors and sub-components.

Precision manufacturing

- Uniquely (for Asia) co-locating design engineers and final assembly lines in Hong Kong.

- Specialisation in complex electromechanical assemblies.

- Motor / mechanism custom end-of-line testing.

Partnership

- We free up your resources and take away the pain of motor mechanisms for higher value R&D.

- Working as an extension of your business, at every stage.

- Pre and post sales support, in your time zone and language.

Managing your risk

- Unparalleled motor mechanism experience, enables us to predict problems and provide solutions.

- Competent skills and processes to mitigate risks from design through to mass production.

- A culture to get things right!

Key markets and applications

We provide motor and mechanism solutions to all sorts of industries, including:

Medical

- Point of care machines

- Lab analysis and diagnostics equipment

- Drug dispensers

- Automated test platforms

- Pumps

- Surgically implanted devices

Instruments

- Monitoring and measuring devices

- Lab sample preparation equipment

- Diagnostics equipment

- Sensors and gauge testing

- Bench-top dispensary equipment

- Electronics test equipment

Industrial

- Emergency services equipment

- Analysis and monitoring devices

- Transport and logistics

- Controllers

- Ticket kiosks and ATM’s

- Robotics and artificial limbs

Consumer

- Touchscreens and smart devices

- Video games and controllers

- Smart homes

- Automotive dashboards

- E-bikes

Security

- Sensors and alarms

- Handheld scanners

- Surveillance cameras and monitors

- Locks, security systems and safes

- Passport readers and ID scanners

Healthcare

- At home health monitoring

- Rehabilitation accessories

- Fitness trackers and smart watches

- Oral drug dispensaries and vapes

- Stairlift and mobility solutions

Case studies

Our DC Gearmotors are used throughout many applications and industries. Here are some of our recent gearmotor projects

-

Smart home

Precision motors for solar-powered, smart-enabled motorised control access system for operating home devices like locks, windows and blinds.

View Case Study

-

Medical laboratory DNA testing equipment

DNA Benchtop medical diagnosis machine redesign to support new commercialisation model.

View Case Study

-

Medical inhaled medication delivery device

Intelligent medical inhaler device, which was FDA Class III approved, required a gear motor mechanism to provide precise dosage for all users.

View Case Study

-

Mobility stairlift

Mobility solution, an indoor stairlift, required a new gear motor mechanism.

View Case Study

-

Swarm robot research linear actuator

Challenging technical and unique application for swarm robotics for a European robotic research Institution.

View Case Study