735-400 – 35mm Brushless Motor

Slotted (outrunner) Ø35 x 15mm / with gimball mount / hall sensors

Request a volume quotation

For higher (production) volumes, we offer highly competitive pricing. Please click on the ‘Request a quote’ button, and complete our volume quotation form. We will respond within 1 business day.

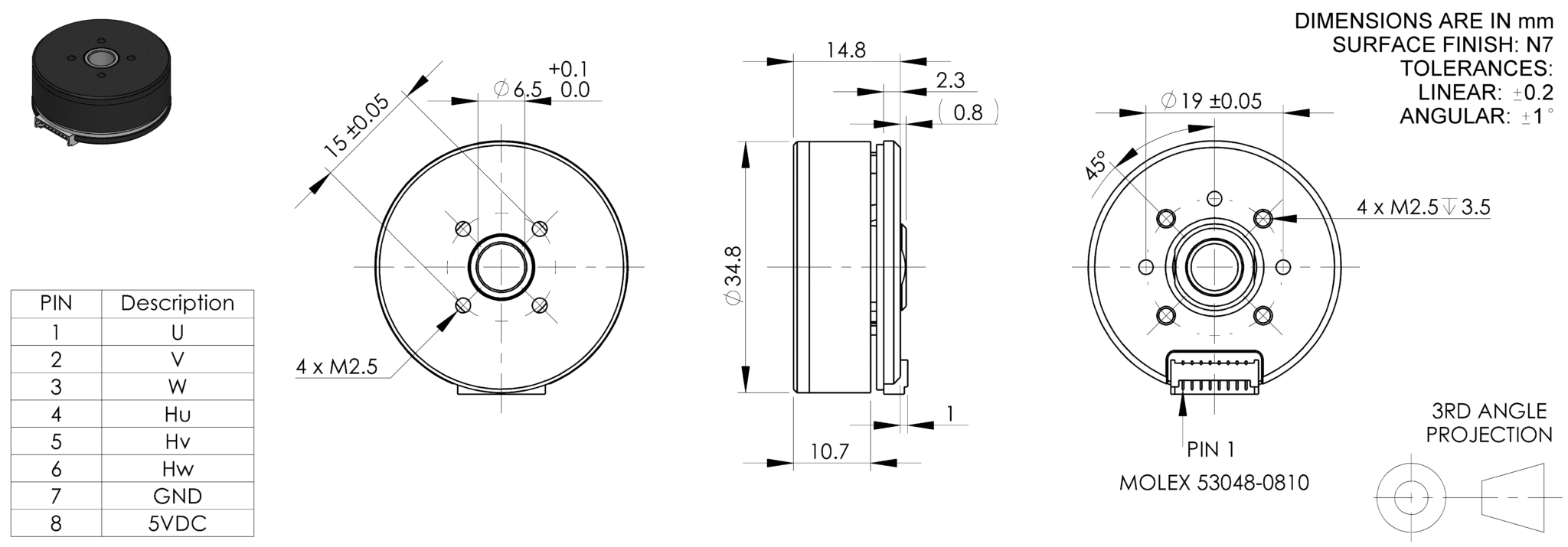

Drawing

Key Features

| Model No. | 735-400 | ||

| Motor Type | Gimball [Slotted] | ||

| Diameter | mm | 35 | |

| Length | mm | 15 | |

| Voltage | V | 12 | |

| No-load Current | A | 0.04 | |

| No-load Speed | rpm | 2360 | |

| Stall Torque | mNm | 102.31 | |

| Stall Current | A | 2.14 | |

| Nominal Torque | mNm | 48.70 | |

| Nominal Speed | rpm | 1210 | |

| Nominal Current | A | 1.06 | |

| Sensor Commutation | Sensor |

Performance characteristics

| Nominal voltage | V | 12 | |

| No load speed | rpm | 2 360 | |

| No load current | A | 0.04 | |

| Nominal speed | rpm | 1 210 | |

| Nominal torque | mNm | 48.70 | |

| Nominal current | A | 1.06 | |

| Stall torque | mNm | 102.31 | |

| Stall current | A | 2.14 | |

| Maximum efficiency | % | 74.00 |

Design and accessories

| Availability | Stocked design | ||

| Motor Type | Brushless | ||

| Commutation | Digital Hall | ||

| Shafts | Not fitted | ||

| Encoder | Not fitted | ||

| Gearbox | Not fitted | ||

| Connections | JST B8B PH1.25 | ||

| Cable | Not fitted | ||

| Housing Material | Aluminium alloy | ||

| Body diameter | mm | 35 | |

| Body length | mm | 15 | |

| Weight | g | 39.1 |

Motor body characteristics

| Thermal resistance housing-ambient | °C/W | 10.0 | |

| Thermal resistance winding-housing | °C/W | 4.5 | |

| Thermal resistance winding-housing | s | 9 | |

| Thermal time constant motor | s | 307 | |

| Ambient temperature | min | °C | -30 |

| max | °C | +100 | |

| Max. permissable winding temperature | °C | +150 | |

| Max. permissable rotor speed | rpm | 12 000 | |

| Radial play | Preloaded | ||

| Max. axial load (dynamic) | kN | 0.8 | |

| Number of pole pairs | 7 | ||

| Number of winding phases | 3 |

Winding specific characteristics

| Terminal resistance | Ω | 5.60 | |

| Terminal inductance | mH | 1.40 | |

| Torque constant (Kt) | mNm/A | 47.75 | |

| Speed constant (Kv) | rpm/V | 200 | |

| Speed / torque gradient | rpm/mNm | 23 | |

| Mechanical time constant | ms | 5.8 | |

| Rotor inertia | g.cm² | 23.9 |

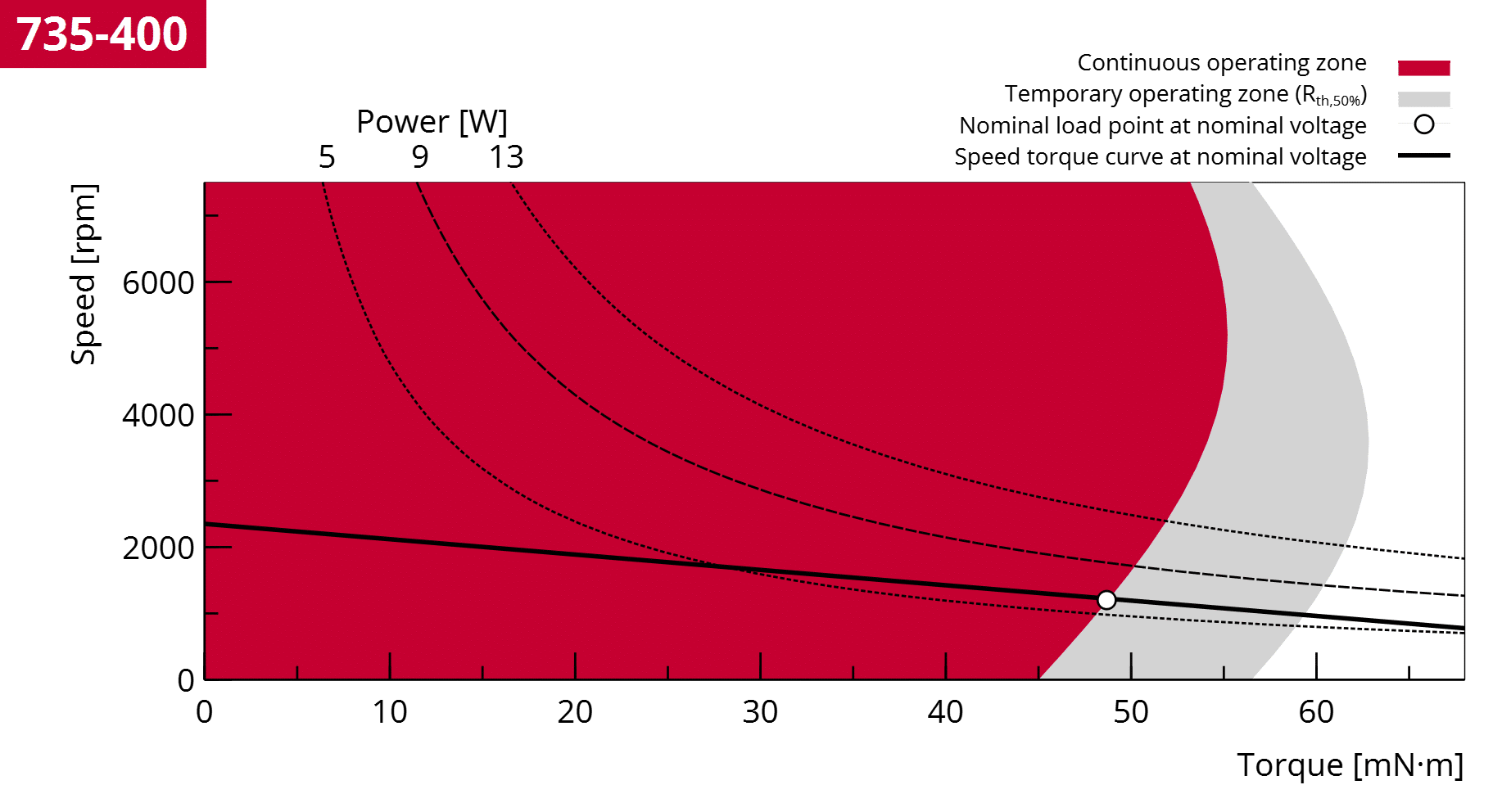

Operating range (based on on ambient 25°C)

For each motor frame size (diameter / length), we present the operating range diagram that relates to the winding of the stock sampleable part. The part number of the stock sampleable part is shown in the diagram below, and the product page of the stock sampleable part, can be found in the ‘related products’ section towards the bottom of the page.

Sample request

We aim to get you up and prototyping as quickly as possible. We stock off-the-shelf samples for each motor size, to support commercial development.

Our application engineers can advise on motor design and selection, mechanism design, and support the development of high performance motor drivers. They can also assist to validate the in-application performance and longevity suitability of a down-selected motor or mechanism design.

Contact our application engineering team to discuss your project, using the form, or email [email protected].